Premium Decorative External Cladding Solutions for Stylish & Durable Exteriors

- Introduction to decorative external cladding

and its industry relevance. - Material innovations and technical advantages influencing cladding choices.

- Comparative analysis of top manufacturers: performance, warranties, and certifications.

- Exploration of custom solutions and design flexibility for diverse building types.

- Practical application cases, including both residential and commercial projects.

- Key considerations for installation, maintenance, and lifecycle value.

- Conclusion: The future outlook for decorative external cladding in sustainable architecture.

(decorative external cladding)

Innovations in Decorative External Cladding Materials

The façade of a building delivers more than just aesthetic appeal; it acts as a protective skin, influencing thermal efficiency, durability, and long-term maintenance needs. Decorative external cladding systems have evolved significantly in recent years, blending cutting-edge materials with advanced finishes. According to a 2023 industry survey, the global cladding market surpassed USD 80 billion, with decorative solutions accounting for approximately 36% of the total volume. This surge is driven by architectural demand for visually striking exteriors, increased regulatory requirements for insulation, and longevity. Technological innovations—such as self-cleaning nano-coatings, UV-resistant surfaces, and ventilated rain screen construction—have redefined the performance benchmarks for modern cladding. Notably, new composite panels and high-density slate configurations rival traditional stone in both appearance and structural resilience, all while reducing installation times by up to 25%.

Technical Advantages: Enhancing Performance and Value

Superior decorative cladding for external walls is defined by multiple performance criteria: weatherproofing, fire resistance, insulation properties, and design versatility. Modern solutions utilize multi-layer composites—ranging from aluminium honeycomb panels to fibre-cement boards—coupled with digital print technology for bespoke surface effects. A critical benefit is weather adaptability; for instance, engineered slate external wall cladding provides outstanding freeze-thaw stability, making it suitable for harsh climates. Data from the International Building Council reveal that buildings retrofitted with advanced cladding materials experience up to 22% improvement in thermal performance and up to 30% savings in annual maintenance costs. Cutting-edge systems also prioritize modular assembly, enabling rapid installation with minimal environmental impact. Customers emphasize aesthetic flexibility—matte, textured, or metallic finishes—ensuring any design vision can be realized without compromising structural function.

Comparative Analysis of Leading Decorative Cladding Manufacturers

Selecting the right cladding supplier is critical to maximize project ROI and long-term satisfaction. The table below contrasts renowned manufacturers specializing in decorative external cladding and slate solutions. Criteria include material range, certifications, warranty terms, and notable technologies.

| Manufacturer | Material Range | Certifications | Standard Warranty | Technical Differentiation |

|---|---|---|---|---|

| Rockpanel | Mineral wool, HPL, Composite | BREEAM, CE, EN13501-1 | 20 years | UV & graffiti protection, low weight, high impact resistance |

| Cupa Pizarras | Pure Slate | CE, NF, ASTM C406 | 100 years (slate) | Automated quarrying, traceable origin, dimensional stability |

| Trespa | HPL, Fibre-cement | ISO 14001, PEFC, EPD | 10 years | Proprietary laminate layering, weather-fast finish |

| Equitone | Fibre-cement | EN12467, BES 6001 | 10 years | Through-coloured panels, monolithic appearance |

| Cembrit | Fibre-cement, Slate | EN13501, ISO 9001 | 30 years (slate) | Multiple colour/texture options, enhanced durability |

As the comparative data suggests, natural slate led by Cupa Pizarras offers unmatched longevity, while composite and fibre-cement alternatives from Rockpanel and Trespa present diverse finish options and ease of installation. Certifications such as CE and ISO reflect commitments to regulatory performance, sustainability, and safety.

Customization and Design Flexibility

A defining quality of contemporary decorative cladding for external walls lies in the near-limitless customization offered. Architects and developers can specify panel dimensions, corner details, perforation patterns, and colour palettes to align with corporate identities or contextual aesthetics. Digital fabrication permits intricate graphic overlays, enabling project branding or the mimicry of rare natural stones. Notably, modular systems can accommodate complex building geometries—such as curved façades or dynamic assemblies—which was previously challenging with traditional materials. Many manufacturers now supply integrated fixing systems, insulation layers, and surface treatments to streamline design-to-installation processes. During the project specification stage, detailed 3D renderings and mock-ups enable previsualization, further reducing design risk and revision cycles. This level of adaptability has catalysed cladding’s role in bespoke, landmark architecture where both identity and performance are paramount.

Application Cases: Decorative External Installations in Action

The impact of advanced cladding solutions becomes evident in built environment case studies. For instance, a London-based mixed-use development utilized ventilated slate external wall cladding to achieve a BREEAM Excellent rating while echoing the site’s historic context; the façade system provided Class A1 fire-rating and required zero remedial maintenance within the first five years. In a Scandinavian office campus, fibre-cement panels with high-contrast textures delivered resilience against snow and freeze-thaw cycles, reducing energy needs by an estimated 19%. In Sydney, a retail centre employed digitally printed composite panels, enabling vibrant, art-like facades that attracted over 20% more pedestrian traffic in the first year of operation. Residential complexes increasingly deploy decorative cladding for external walls to improve curb appeal and resale value, often reporting an uplift of 8-12% in final sale prices relative to non-upgraded comparables.

Installation, Maintenance, and Lifecycle Considerations

Installation efficiency is a crucial factor in the adoption of decorative cladding. The latest panelized systems support rapid mounting directly onto sub-frames, often reducing on-site installation time by up to 30% compared to legacy methods. Prefabrication ensures dimensional accuracy and minimizes on-site waste, contributing to LEED and other green building certifications. Lifecycle durability varies by material: natural slate is virtually inert and retains its integrity for over a century, while advanced composites deliver 20-30 years of low-maintenance performance. Maintenance typically involves periodic washing and, for some metallic finishes, reapplication of protective coatings. According to a recent facilities management survey, buildings equipped with high-quality decorative cladding report 35% fewer water ingress or efflorescence incidents over a 10-year period. Considering both aesthetic longevity and operational cost savings, lifecycle value strongly favors high-performance systems from reputable manufacturers.

The Future of Decorative External Cladding in Sustainable Architecture

Decorative external cladding stands at the forefront of sustainable architectural evolution. Adoption is accelerating globally, aligned with initiatives promoting energy efficiency, material circularity, and enhanced urban environments. With technical advancements, custom fabrication, and a proven track record across diverse climates, decorative cladding systems—including slate external wall cladding—are positioned to dominate future façade design. Stakeholders are increasingly prioritizing carbon footprint reduction and cradle-to-cradle certifications, ensuring benefits from reduced embodied energy and recyclability. As policy and market forces intensify, investment in robust and aesthetically versatile cladding will become not only a creative choice but also an operational and ecological imperative. Architects, developers, and building owners seeking to secure long-term value and environmental compliance will find in decorative external cladding an essential ally for years to come.

(decorative external cladding)

FAQS on decorative external cladding

Q: What is decorative external cladding?

A: Decorative external cladding refers to materials added to a building's outer walls to improve appearance and provide extra protection. It’s available in various finishes and styles. This enhances both aesthetics and durability.Q: Why choose decorative cladding for external walls?

A: Decorative cladding for external walls boosts your property’s curb appeal and value. It also provides a layer of insulation and weather resistance. Many materials, including stone, metal, and composites, are available.Q: What are the benefits of slate external wall cladding?

A: Slate external wall cladding is known for its natural, elegant look and longevity. It is highly resistant to weather, fire, and pests. Plus, it requires minimal maintenance over time.Q: Is decorative external cladding easy to install?

A: Many cladding systems are designed for quick and straightforward installation. Professional installers can complete most projects within a few days. Some materials even offer DIY-friendly options.Q: Can decorative cladding be customized for unique designs?

A: Yes, decorative external cladding comes in numerous textures, colors, and patterns. Customization helps match the cladding to your specific architectural style. This allows for completely unique exterior designs.-

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >Aug 05 2025

-

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >Aug 05 2025

-

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >Aug 05 2025

-

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >Aug 05 2025

-

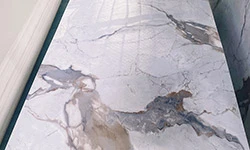

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >Aug 05 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com