WPC Wall Panel Expansion Gaps

Professional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance. Whether working with WPC wall panel systems or comprehensive WPC cladding projects, understanding and properly implementing expansion principles is critical for successful outcomes. This detailed guide examines all aspects of expansion gap management for wood-plastic composite wall systems.

Critical Importance of Expansion Gaps in WPC Wall Cladding

- Essential for accommodating thermal expansion and contraction of WPC wall panel materials during temperature fluctuations

• Prevents unsightly buckling, warping, and structural damage in WPC cladding installations

• Allows for natural material movement caused by humidity and weather changes

• Maintains proper ventilation and drainage behind panels to prevent moisture buildup

• Preserves structural integrity and load-bearing capacity of the entire system

• Ensures long-term dimensional stability and prevents premature aging

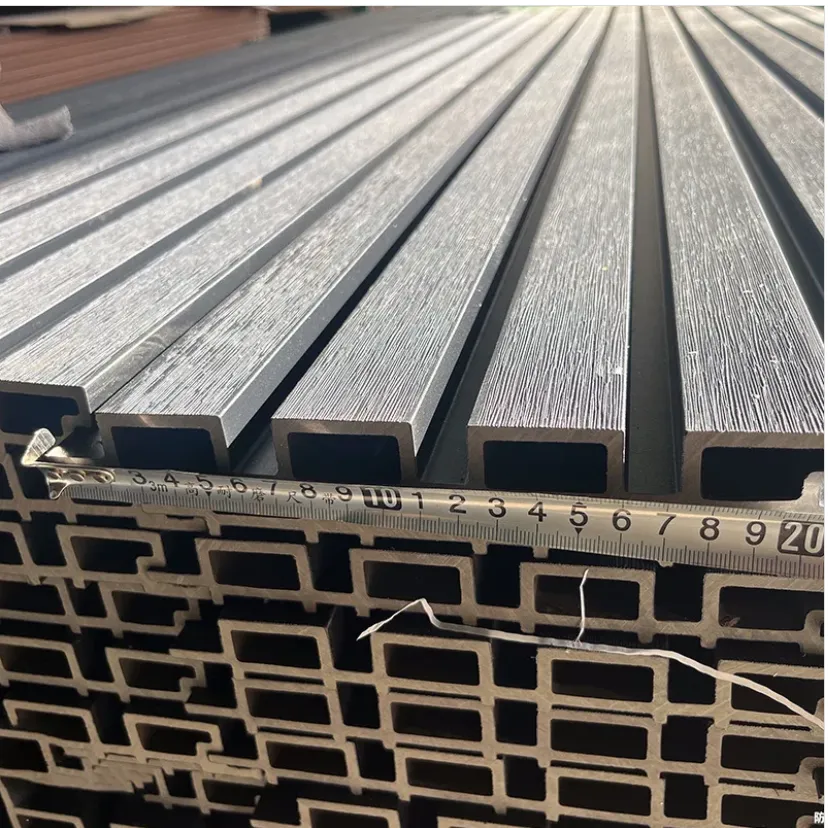

Precise Gap Specifications for WPC Wall Panel

- Standard 6-8mm side gaps between adjacent WPC wall claddingpanels

• 10-12mm perimeter gaps required at all walls, ceilings, and fixed obstacles

• 3-5mm end joints recommended for WPC claddingplank connections

• Increased gap sizes of 10-15% necessary in extreme climate zones

• Manufacturer-specific recommendations that may vary by product line

• Special considerations for south-facing installations with greater sun exposure

• Additional spacing requirements for installations over 15 linear meters

Professional Installation Techniques for Proper Gaps

- Use calibrated spacer tools specifically designed for WPC wall panelinstallations

• Clearly mark gap measurements on substrate before beginning installation

• Maintain perfectly consistent spacing throughout entire WPC claddingproject

• Adjust gap sizes based on ambient temperature during installation

• Account for future building movement and settling in gap planning

• Implement sequential installation patterns to distribute movement evenly

• Use laser levels for maintaining straight gap lines over long runs

Specialized Materials for Gap Management in WPC Wall Cladding

- High-quality, color-matched silicone sealants formulated for WPC wall panelsystems

• Durable expansion trim profiles in matching colors

• Ventilated closure strips that maintain airflow while concealing gaps

• Backer rod insulation for large perimeter gaps in WPC cladding

• Protective edge trims with built-in expansion capabilities

• UV-resistant gap filler compounds for exterior applications

• Specialized joining accessories for corner and transition areas

Climate-Specific Considerations for WPC Wall Panel

- 15-20% larger gaps recommended in desert climates with extreme temperature swings

• Moisture expansion factors critical for WPC claddingin tropical environments

• Special calculations required for seasonal movement in continental climates

• Northern vs. southern exposure differences in gap requirements

• Coastal environment adjustments for salt air and humidity

• High-altitude considerations for increased UV exposure

• Wind load factors affecting gap stability

Long-Term Maintenance of Expansion Gaps

- Annual inspection schedule for WPC wall claddinggap integrity

• Cleaning procedures for gap areas to prevent debris buildup

• Sealant refreshment timeline (typically every 3-5 years)

• Monitoring for signs of insufficient gaps (buckling, warping)

• Seasonal checks before extreme weather periods

• Professional assessment recommendations

WPC Wall Cladding FAQS

Q: How does WPC wall panel installation differ from WPC wall cladding for interior walls?

A: WPC wall panels often feature interlocking or tongue-and-groove systems, making them quick to install on flat surfaces, ideal for accent walls or room dividers. WPC wall cladding, meanwhile, may require additional framing or battens for support, especially in uneven areas, and is better suited for covering large exterior or interior surfaces. Panels typically prioritize aesthetics, while cladding emphasizes durability and weather resistance for long-term use.

Q: What factors should buyers consider when choosing between WPC wall cladding and WPC cladding for outdoor applications?

A: Both WPC wall cladding and WPC cladding are suitable for outdoor use, but focus on product specifications. Look for WPC wall cladding with enhanced UV resistance and waterproof coatings for vertical surfaces exposed to rain and sun. WPC cladding (a more general term) might include horizontal or decorative options; ensure it has proper drainage channels to prevent moisture buildup. Also, check for anti-fungal treatments to avoid mold growth in humid environments.

Q: Can WPC cladding be customized to match the design of WPC wall panels in a renovation project?

A: Yes, WPC cladding and WPC wall panels can be customized for cohesive designs. Manufacturers offer a range of colors, textures (like wood grain or smooth finishes), and profiles. For a unified look, request samples to match shades and patterns across both materials. Some suppliers even provide CNC cutting services for custom shapes or logos, allowing you to blend cladding on exteriors with panels on interior feature walls seamlessly.

Q: How does the maintenance of WPC wall panel compare to WPC cladding in high-traffic areas?

A: WPC wall panels in interior high-traffic zones may require more frequent cleaning to remove scuffs and stains, but they generally resist scratches well. Use a soft cloth and mild detergent for upkeep. WPC cladding, especially outdoors, needs periodic checks for weather damage (e.g., fading or warping). Hose down regularly to remove dirt and debris, and inspect joints for any signs of water infiltration. Both materials benefit from avoiding abrasive cleaners to preserve their protective finishes.

Q: Are there eco-friendly options available for WPC wall cladding and WPC wall panel?

A: Many WPC wall cladding and WPC wall panel products are eco-friendly, as they’re typically made from recycled wood fibers and plastics, reducing waste. Look for certifications like FSC (Forest Stewardship Council) for sustainable wood sourcing or GreenGuard for low chemical emissions. Some manufacturers also use bio-based plastics in production, further minimizing environmental impact. Choosing these options ensures both functional benefits and a reduced carbon footprint in your projects.

Welcome to Shijiazhuang Sothink Trading Co., LTD! Since 2011, we've been a leading force in the building and decoration materials industry. Located in Shijiazhuang, just 300km from Beijing, our strategic position supports seamless global trade. With over a decade of experience, we've successfully expanded our reach, exporting products to North America, South America, Europe, the Middle East, and Africa.

Our all - round services spanning product development, production, and sales ensure high - performance products and top - notch service. Our rich experience and advanced technical expertise have earned us the trust of customers worldwide. Explore our wide range of products like PVC marble sheets, WPC panels, and SPC flooring at https://www.sothinkdecor.com/ and discover quality solutions for your projects.

-

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >Aug 05 2025

-

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >Aug 05 2025

-

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >Aug 05 2025

-

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >Aug 05 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com