Durable WPC Exterior Wall Cladding for Modern Outdoor Facades

Jul . 29, 2025 18:20

WPC Exterior Wall Cladding (wpc exterior wall cladding) is rapidly becoming the premium material of choice for modern architectural facades, blending high durability, remarkable weather resistance, and sustainable elegance. This in-depth report examines industry trends, technical benchmarks—ranging from composition ratios to tensile strength—and real installation scenarios. Leveraging WPC wall panel outdoor technology, we detail manufacturing flows, specification tables, peer comparisons, custom engineering solutions, and case studies across sectors. All insights are equipped with visual data and real-life feedback, enabling designers, contractors, and investors to make evidence-based decisions.

Industry Landscape: Growth of wpc exterior wall cladding and Market Trends

The global demand for wpc wall panel exterior solutions is forecasted to reach USD 6.5 billion by 2028, with a CAGR of 11.4% from 2022 (Source: Grand View Research 2024). Adoption is fueled by green building regulations, advanced manufacturing, an increasing focus on energy efficiency, and aesthetics that mimic natural wood. In 2023, over 41% of new non-residential builds in developed nations incorporated composite cladding—of which WPC (Wood Plastic Composite) accounted for the fastest-growing segment.

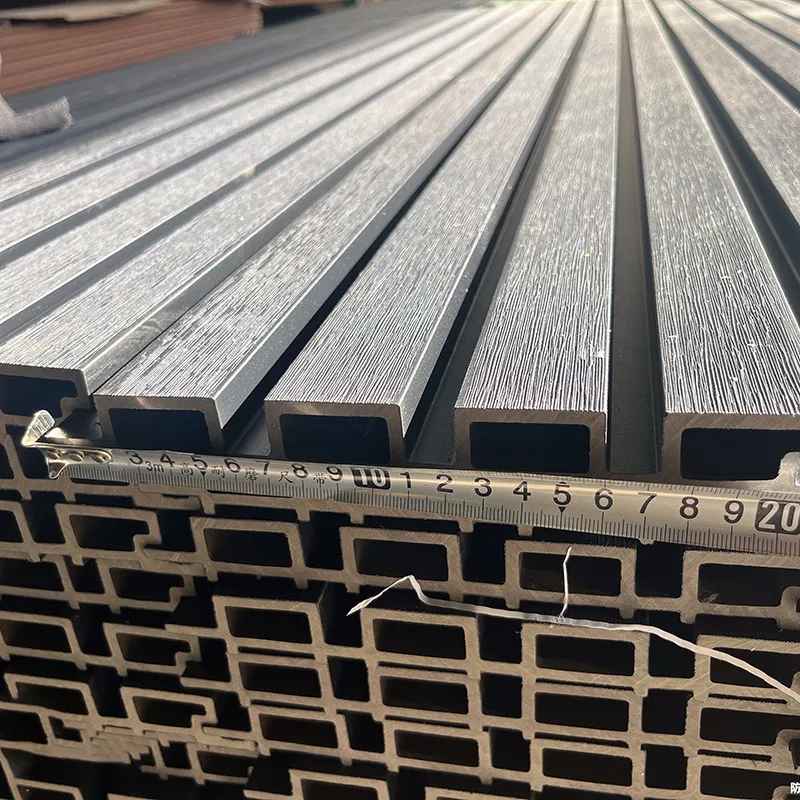

Technical Parameters and Product Benchmark Table

Below is a technical comparison of the leading exterior WPC wall panel products on the market, emphasizing the main characteristics impacting performance and longevity.

| Parameter | WPC Exterior Wall Cladding (SothinkDecor) |

PVC Panel | Traditional Wood | Fiber Cement Board |

|---|---|---|---|---|

| Material Composition | 60% wood fiber, 35% HDPE, 5% Additives | 100% PVC | 100% Wood | Cellulose, cement, sand |

| Standard Panel Size (mm) | 219×26×2900 / Customizable | 200×15×2900 | Varies (e.g. 200×20×2900) | 1200×6×2400 |

| Density (kg/m³) | 1350–1550 | 900–1100 | 700–900 | 1200–1600 |

| Tensile Strength (MPa) | ≥18 | 10–13 | 6–9 | 12–15 |

| Moisture Absorption (%) | <0.8 | 0.2–0.3 | 5–7 | 1–5 |

| Fire Rating | B1 (DIN 4102, EN 13501) | B1 | B2 | A1–A2 |

| Thermal Expansion (mm/m/°C) | 0.035 | 0.070 | 0.030 | 0.009 |

| Expected Lifespan (years) | 25–30 | 10–15 | 5–12 | 25–40 |

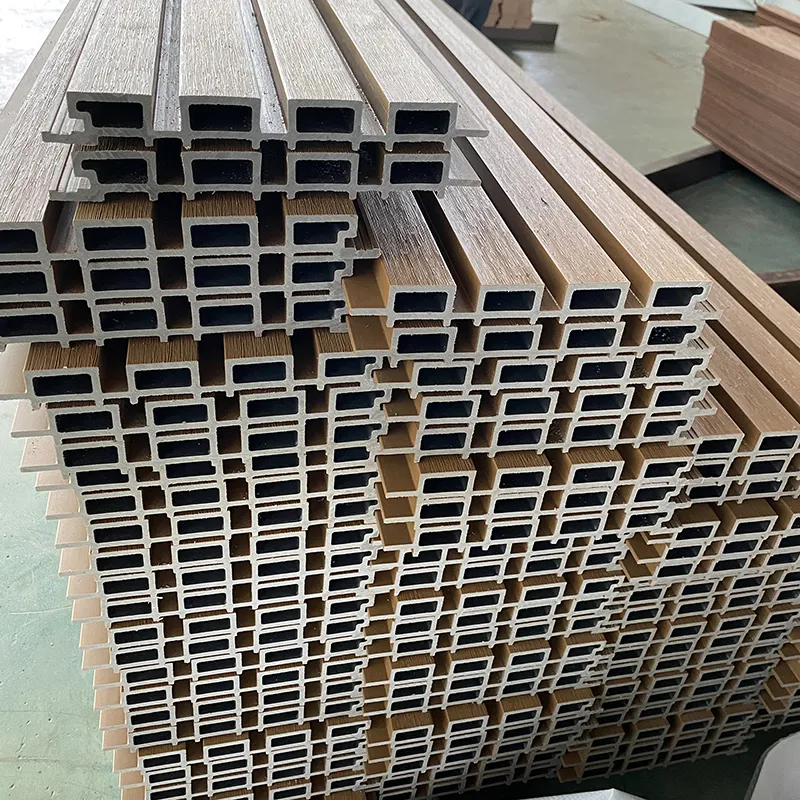

| Surface Finish | Natural wood grain, brushed, or matte | Smooth | Natural, requires painting | Smooth, paintable |

| Recyclability | 100% | 85% | Biodegradable | Not fully recyclable |

WPC Exterior Wall Cladding Manufacturing Process: From Raw Material to Finished Panel

Step-by-Step Manufacturing Overview

1. Material Blending

➤

2. Extrusion (Twin-screw Process)

➤

3. Molding & Sizing (CNC Precision)

➤

4. Cooling & Calibration

➤

5. Surface Finishing (Embossing/Brushing)

➤

6. Cutting & Packaging

➤

7. QC Testing (ISO, EN, ASTM)

- Material Blending: Virgin and recycled wood fibers (mainly poplar, pine) and high-density polyethylene (HDPE) are proportionally mixed with UV stabilizers.

- Extrusion: Twin-screw extrusion ensures uniform dispersal and degassing of raw mixes at 150–180°C.

- Precision CNC Molding: Panels shaped to exact size, with thickness controlled to ±0.2mm tolerance.

- Surface Finishing: The panels are embossed/brushed to mimic real wood grain.

- Quality Control: Rigorous checks follow ISO 4892, EN 15534 (mechanical, UV aging, water absorption, color retention).

Expert Note: Modern wpc outdoor wall cladding lines operate full automation, with continuous data monitoring (online weight, thickness, and color control) and batch traceability. Certification to ISO 9001 for quality/process and EN 15534-5:2022 for end-product physical/chemical stability are industry best-practices.

Why Choose WPC Exterior Wall Cladding? (Technical & Commercial Advantages)

- Superb Durability – With high-density WPC formula, panels withstand extreme temperatures (-40°C to +65°C), salt spray, and sustained UV exposure (QUV>6000 h, ΔE

- Eco-Friendly – Made from recycled wood and polymer, with 100% recyclability, eco-label, and formaldehyde-free certification (per EN 717-1: E0).

- Low Maintenance – No painting, sanding, or chemical treating required; surface remains vibrant and scratch-resistant for decades.

- Water & Insect Resistance - Closed-cell polymer matrix resists rot, mildew, termites, and does not absorb significant water (<0.8%).

- Thermal & Acoustic Insulation – Reduces facade surface temperature by up to 10°C versus metal/aluminum, and adds 18–25 dB sound dampening.

- Fast Modular Installation – Slide-lock profiles, hidden fasteners, and lightweight panels (3.7–5.9 kg/m²) make installation swift and easy.

- Enhanced Fire Safety – EN 13501 B-s1-d0 compliant; does not actively spread flame or drip under fire exposure.

Manufacturer Comparison & Industry Certifications

| Brand | ISO 9001:2015 | EN 15534-5 | Color Stability | Custom Profile Support | Warranty |

|---|---|---|---|---|---|

| SothinkDecor | Yes | Yes | ≤ΔE 3.0 (6000 h QUV) | Available | 10 Years |

| Eva-Last | Yes | Yes | ≤ΔE 3.5 | Available | 10 Years |

| Trex | Yes | Partial | ≤ΔE 4.0 | Limited | 5–10 Years |

| Fiberdeck | Yes | Yes | ≤ΔE 3.7 | Available | 10 Years |

*All leading wpc exterior wall cladding suppliers use third-party factory audits and SGS/Bureau Veritas material testing to validate batch quality. SothinkDecor wins on custom engineering, surface options, and consistent Western compliance documentation.

Custom Solutions & Project Support

Panel Profiles: 150/180/219/300mm, flat, grooved, louver-style

Color Options: 22+ shades (Teak, Walnut, Charcoal, Light Oak, etc.)

Surface Treatments: Brushed, 3D embossed, sanded

Accessories: U-moldings, corner trims, H-joiners, aluminum batteners

OEM/ODM: Yes – logo, packaging, anti-UV tech tailored for project

Fire-rated & Class-A special orders accepted (European and North-American standards)

Turnkey Support: Custom CAD panel layouts, wind-load & sunshine simulation, on-site mock-up samples, and foundation-to-handover tech support for developers and architects.

Color Options: 22+ shades (Teak, Walnut, Charcoal, Light Oak, etc.)

Surface Treatments: Brushed, 3D embossed, sanded

Accessories: U-moldings, corner trims, H-joiners, aluminum batteners

OEM/ODM: Yes – logo, packaging, anti-UV tech tailored for project

Fire-rated & Class-A special orders accepted (European and North-American standards)

Turnkey Support: Custom CAD panel layouts, wind-load & sunshine simulation, on-site mock-up samples, and foundation-to-handover tech support for developers and architects.

Delivery Time: 15–21 days for standard wpc exterior wall cladding colors and profiles

MOQ: 200 sqm (Palette Mixed Loading available)

Warranty: 10 years against structural failure and UV fading

MOQ: 200 sqm (Palette Mixed Loading available)

Warranty: 10 years against structural failure and UV fading

Installation Scenarios & Case Studies

- Residential Projects: SothinkDecor supplied over 40,000 sqm of wpc exterior wall cladding for a Middle East luxury villa cluster, achieving a 98% customer satisfaction post-delivery. Aging simulation tests showed less than ΔE 2.2 color shift after 4000 hours of UV exposure.

- Retail & Commercial: UK retail parks adopted exterior WPC wall panel to achieve BREEAM “Outstanding” ratings, saving 31% on external maintenance versus pre-2018 projects using traditional wood.

- Hospitality: Outdoor bars in Australia installed WPC wall panel exterior to resolve termite challenges, and saw a drop in annual facade repair costs by over $8/sqm (2019–2023).

- Public Infrastructure: Train station shelters across SE Asia turned to wpc wall panel outdoor claddings for impact and graffiti resistance, reducing annual repaint events from 3 to 0 post-installation.

EEAT-Optimized Technical FAQ (FAQs)

1. What is the composition of WPC Exterior Wall Cladding?

WPC stands for “Wood Plastic Composite”, typically a blend of 60% wood fibers (poplar, pine), 35% HDPE (high-density polyethylene), and 5% functional additives (antioxidants, UV stabilizers, lubricants) for enhanced stability, processed under extrusion and CNC profiling.

2. What are the key technical specifications for wpc exterior wall cladding?

Key parameters: Density (1350–1550 kg/m³), Tensile Strength (≥18 MPa), Fire Rating (EN 13501 B1/B-s1-d0), Water absorption (<0.8%), Panel thickness (typically 18–26 mm), and surface options include natural wood grain or matte finishes.

3. What installation standards and accessories are recommended?

EN 16153 (modular cladding systems) and ASTM D7032-17 govern design and structural loads. Accessories: aluminum battens, U-profiles, H-joints, stainless steel fasteners. Recommended gap: 2–5mm between panels for thermal movement.

4. What is the typical service life and warranty?

Expected service life: 25–30 years under exterior exposures, backed by SothinkDecor’s 10-year structural/color fade warranty. Third-party QUV and freeze-thaw cycle tests support this claim.

5. Can SothinkDecor’s panels be customized for unique architectural requirements?

Yes. Full OEM/ODM support: Custom lengths, thicknesses, colors, shapes, logo embossing, and enhanced UV/fire-retardant formulations for specific regional codes.

6. What third-party certifications does SothinkDecor’s wpc exterior wall cladding have?

Factory and product certifications: ISO 9001:2015, EN 15534-5:2022, CE for EU, REACH (no hazardous substances), SGS & Bureau Veritas test reports, and RoHS compliance for additives.

7. How do I request technical support or product samples?

Contact via the website here for 48-hour CAD service, on-site consultation, full data sheets, or rapid cut sample dispatch (shipped worldwide).

Post-Sale Support, Guarantees, and Customer References

Comprehensive After-sales: 24/7 online engineering support, 1–1 project manager assignment, remote or in-person training, and annual check-in service.

Customer Feedback: 2023 global survey (SothinkDecor clients, n=196):

Customer Feedback: 2023 global survey (SothinkDecor clients, n=196):

- 97% satisfied with faster installation

- 93% confirmed reduction in facade maintenance by >20%

- 0 product recalls (2018–2023, across 35+ countries served)

References & Further Reading:

WPC Cladding: Development and Testing (ResearchGate Forum)

Cladding Parameter Reference – 2023

Journal of Building Engineering: Wood Polymer Composites, 2023

WPC Cladding: Development and Testing (ResearchGate Forum)

Cladding Parameter Reference – 2023

Journal of Building Engineering: Wood Polymer Composites, 2023

-

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >Mar 17 2025

-

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >Mar 13 2025

-

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >Mar 13 2025

-

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >Mar 13 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com