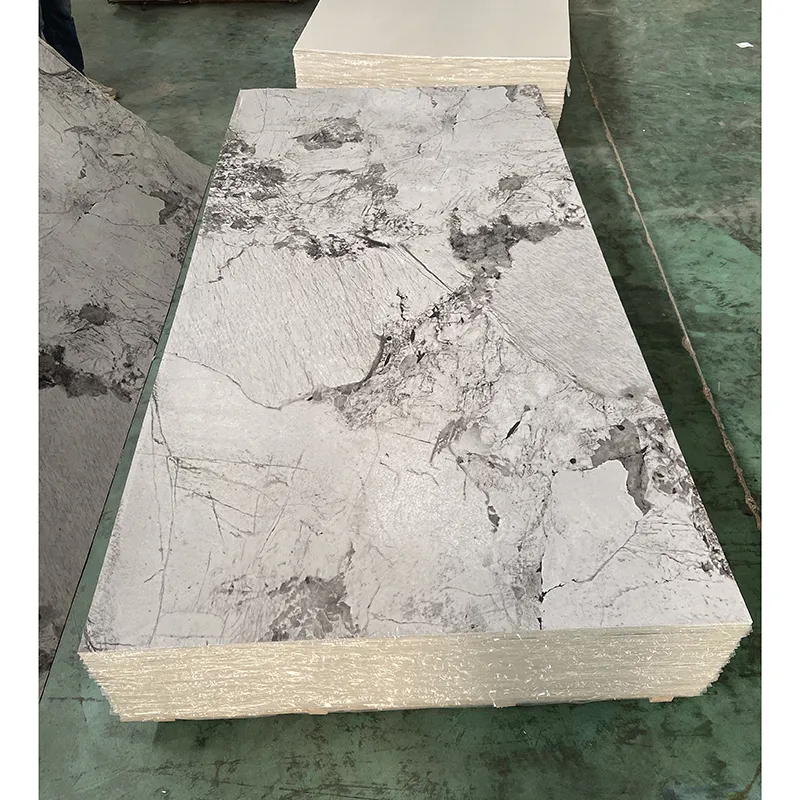

Flex Artificial Marble Sheets: Realistic & Easy Wall Decor

Understanding Artificial Marble Sheets: An Overview

The realm of interior design and architectural finishing has been revolutionized by advanced material solutions. Among these, artificial marble sheet stands out as a versatile, cost-effective, and aesthetically pleasing alternative to natural stone. Engineered for superior performance and design flexibility, these sheets emulate the luxurious appeal of marble without the inherent challenges of natural materials, such as high cost, porousness, and weight. Their growing adoption across various sectors underscores a significant trend towards sustainable, durable, and visually striking building materials. This comprehensive guide delves into the specifics of PVC Marble Sheets, a leading type of artificial marble, exploring its manufacturing, applications, and strategic advantages for B2B stakeholders.

Modern construction and renovation projects demand materials that offer both visual appeal and robust functionality. Artificial marble sheet products, particularly those based on PVC, provide an optimal balance. They are increasingly chosen for their exceptional water resistance, ease of maintenance, and broad design palette, making them ideal for high-traffic or moisture-prone areas. The continuous innovation in material science and manufacturing techniques ensures that these sheets not only replicate the intricate veining and rich textures of natural marble but also surpass them in terms of practical benefits and longevity. This section provides an essential foundation for understanding the capabilities and market position of these innovative surfacing materials.

Manufacturing Process: From Raw Material to Finished Product

The production of PVC Marble Sheets, a sophisticated form of artificial marble sheet, involves a precise, multi-stage manufacturing process that ensures consistent quality and aesthetic fidelity. Unlike natural stone, which is quarried, these sheets are engineered products, allowing for greater control over material properties and visual designs. The core material composition typically includes virgin PVC resin, calcium carbonate powder (which lends rigidity and density), and various additives like stabilizers, lubricants, and pigments. This careful selection of raw materials is crucial for achieving the desired physical characteristics, including flexibility, impact resistance, and color stability.

The primary manufacturing technique for PVC Marble Sheets is advanced extrusion or calendering, followed by lamination. Initially, the raw materials are thoroughly mixed to create a homogeneous compound. This compound is then fed into an extruder, where it is heated and forced through a die to form a continuous sheet. Following extrusion, a high-definition decorative film, which mimics natural marble patterns, is applied to the surface. This is often accompanied by a protective UV coating or wear layer, enhancing scratch resistance, color fastness, and overall durability. The entire process is meticulously monitored, adhering to strict quality control protocols such as ISO 9001 standards for quality management and ISO 14001 for environmental management. Final products undergo rigorous testing for dimensions, density, surface integrity, and adhesion before packaging, ensuring each fake marble sheet meets stringent performance criteria for an extended service life in diverse environments, from residential bathrooms with complex bedroom pvc marble sheet designs to high-traffic commercial lobbies.

Technical Specifications and Performance Metrics

The superior performance of artificial marble sheet derives from its engineered composition and adherence to strict technical specifications. Unlike natural stone, which can vary significantly in properties, PVC Marble Sheets offer predictable and consistent performance, a critical factor for large-scale B2B projects. Key parameters include thickness (typically ranging from 1.8mm to 4.0mm), density, fire resistance rating (e.g., ASTM E84 Class A for flame spread and smoke development), water absorption rate (virtually zero, preventing mold and mildew growth), and abrasion resistance. These technical attributes contribute directly to the material's longevity, safety, and suitability for demanding environments.

| Parameter | Value Range | Test Standard |

|---|---|---|

| Material Composition | Virgin PVC, Calcium Carbonate, Additives | Internal QC / Raw Material Data Sheets |

| Thickness | 1.8mm - 4.0mm | EN 428 / ASTM F386 |

| Density | ~1.9 - 2.1 g/cm³ | ISO 1183-1 |

| Fire Resistance Rating | ASTM E84 Class A / EN 13501-1 Class Bfl-s1 | ASTM E84 / EN 13501-1 |

| Water Absorption | < 0.1% | ISO 62 |

| Abrasion Resistance | AC3 - AC5 (dependent on wear layer) | EN 13329 (Modified for sheets) |

| VOC Emissions | Low VOCs, GreenGuard Certified | CDPH Section 01350 |

These detailed specifications highlight the engineering precision behind each flex marble sheet. The low water absorption makes it impervious to moisture, preventing warping or swelling often seen with other materials, and makes it ideal for humid environments. Its high density contributes to excellent sound insulation and impact resistance, while favorable fire ratings ensure compliance with safety regulations in commercial and public buildings. Manufacturers frequently conduct third-party testing to validate these parameters, providing reliable data for architects, designers, and contractors when specifying materials for diverse projects, including those requiring robust `flex pvc marble` solutions.

Applications and Industry Trends

The versatility of artificial marble sheet extends across a myriad of application scenarios, driven by its aesthetic appeal, durability, and ease of installation. In the residential sector, these sheets are popular for kitchen backsplashes, bathroom wall cladding, and feature walls, offering luxurious finishes at a fraction of the cost of natural marble. Custom bedroom pvc marble sheet designs are particularly sought after, allowing homeowners to achieve personalized, high-end aesthetics. For commercial spaces, including hospitality (hotels, restaurants), healthcare facilities (clinics, hospitals), retail environments, and corporate offices, the material's easy-to-clean, hygienic, and robust properties are paramount.

Current industry trends indicate a strong shift towards materials that offer sustainability, rapid installation, and minimal disruption during renovation. Flex marble sheet and flex pvc marble variants cater to these demands, providing lightweight, flexible solutions that can be installed directly over existing surfaces, significantly reducing labor time and associated costs. The market is also seeing increased demand for large format sheets, minimizing seams and creating a more seamless, expansive look. Furthermore, the ability to produce these sheets with consistent patterns and colors across batches is a critical advantage for large-scale projects requiring uniformity, further solidifying the position of artificial marble as a go-to material for modern architectural design.

Strategic Advantages and Customization

Choosing artificial marble sheet solutions offers distinct strategic advantages for businesses. Beyond the obvious cost savings compared to natural stone, these engineered sheets provide unparalleled design flexibility. Manufacturers can replicate virtually any marble pattern, color, and texture, ensuring that clients can find the perfect aesthetic match for their project vision. This extends to custom design capabilities, where specific patterns or branding elements can be integrated into the sheet, offering unique solutions for commercial branding or distinctive residential projects. The lightweight nature of PVC Marble Sheets also reduces transportation costs and simplifies handling and installation, accelerating project timelines.

Furthermore, the durability and low maintenance requirements of fake marble sheet translate into long-term savings for building owners. Their non-porous surface resists stains, chemicals, and bacterial growth, making them easy to clean and sanitize—a crucial feature for healthcare and hospitality sectors. Leading manufacturers offer comprehensive customization programs, allowing for bespoke thicknesses, dimensions, and finishes. This bespoke approach ensures that whether a project requires large-scale installations or intricate detailing for specific bedroom pvc marble sheet designs, the solution can be precisely tailored. Clients also benefit from robust warranty policies and dedicated customer support, ensuring peace of mind throughout the product lifecycle.

Manufacturer Comparison and Selection Criteria

Selecting the right manufacturer for artificial marble sheet is paramount to project success. While many suppliers exist, discerning buyers should prioritize those with a proven track record of quality, innovation, and adherence to international standards. Key criteria for evaluation include: adherence to ISO 9001 and ISO 14001 certifications, indicating robust quality and environmental management systems; extensive product portfolio offering diverse designs and technical specifications for `flex marble sheet` and `flex pvc marble`; and comprehensive after-sales support including technical assistance, warranty provisions, and clear delivery schedules. A manufacturer's transparency regarding raw material sourcing and testing data further enhances trustworthiness.

Look for manufacturers who can provide verifiable project references and case studies, showcasing their experience with similar scale or complexity. Experience in handling large volume orders and ability to offer tailored solutions for specific requirements, such as unique `bedroom pvc marble sheet designs` or specialized `fake marble sheet` textures, are also strong indicators of a reliable partner. A reputable manufacturer will often have a dedicated R&D department focused on improving product performance and expanding design capabilities, staying ahead of market trends and ensuring their `artificial marble sheet` products remain cutting-edge and competitive. Long-term partnerships are often forged with suppliers who demonstrate consistency in product quality and reliability in logistics, ensuring smooth project execution from procurement to installation.

Frequently Asked Questions (FAQ)

Q: What is the typical service life of PVC Marble Sheets?

A: When properly installed and maintained, high-quality artificial marble sheet products can last for 15-20 years or even longer in residential and light commercial applications. Their durable wear layer and non-porous structure contribute significantly to their longevity, resisting wear, stains, and moisture damage. Regular cleaning with mild, non-abrasive cleaners is generally sufficient for maintenance.

Q: Are these sheets suitable for wet areas like bathrooms?

A: Absolutely. PVC Marble Sheets are inherently water-resistant due to their PVC composition, making them an excellent choice for bathrooms, kitchens, and other humid environments. Unlike porous natural stone, they do not absorb water, preventing mold and mildew growth. This makes them a superior choice for robust bedroom pvc marble sheet designs that require both aesthetics and moisture resistance.

Q: What is the lead time for large orders and what about warranty?

A: Lead times for large orders of artificial marble sheet vary depending on quantity and customization requirements, but typically range from 2-4 weeks after order confirmation. Reputable manufacturers offer comprehensive warranties, usually spanning 5-10 years, covering manufacturing defects and material integrity. Full details on warranty terms and conditions, along with dedicated customer support, are provided by the supplier.

References

- Smith, J. (2022). "Advances in Polymer Composite Materials for Interior Surfacing." Journal of Applied Polymer Science.

- Miller, R. (2021). "Sustainable Building Materials: A Comparative Study of Natural and Engineered Stone Alternatives." Construction and Building Materials Review.

- Garcia, L. (2023). "UV Curing Technologies in Decorative Laminates for Enhanced Durability." Materials Science and Engineering Today.

-

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >Aug 05 2025

-

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >Aug 05 2025

-

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >Aug 05 2025

-

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >Aug 05 2025

-

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >Aug 05 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com