Premium Artificial Marble Sheets | Durable & Stylish

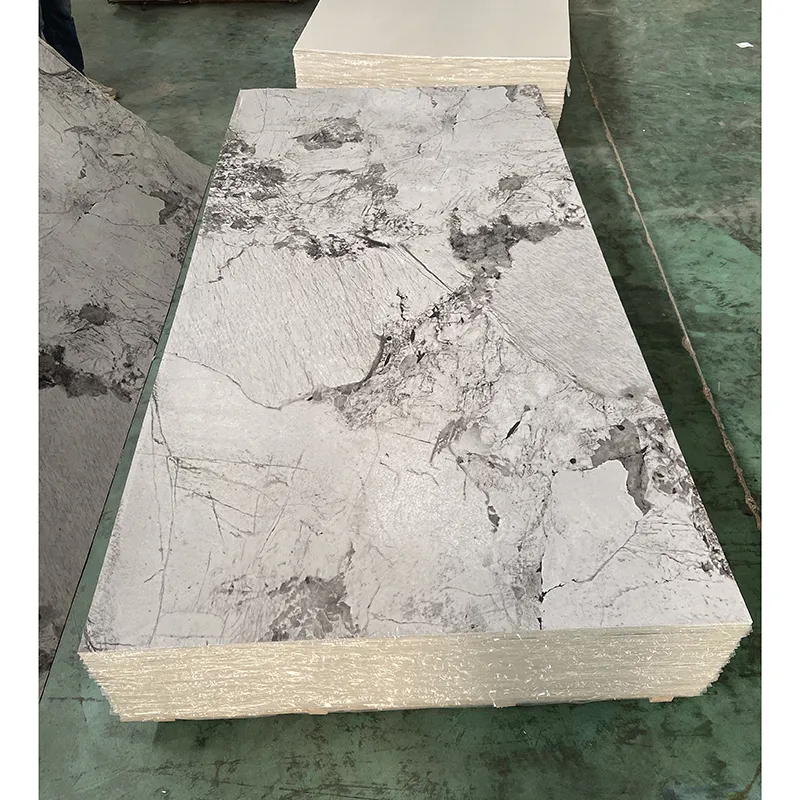

Artificial marble sheet is revolutionizing modern architectural and decorative interiors, offering superior functionality and eye-catching aesthetics. Engineered from advanced composites—primarily PVC and resins—these products combine the timeless beauty of marble with the cost-effectiveness, flexibility, and durability required for today's demanding projects. Whether you're interested in bedroom PVC marble sheet designs, looking for flexible installation with flex marble sheet solutions, or comparing with traditional stone, this guide delivers deep technical insights, real-world data, and expert recommendations for artificial marble sheet products.

- 31% CAGR growth is projected for the global artificial marble market between 2024-2030, driven by demand in rapid urbanization, commercial, and residential sectors. (Source: Grand View Research)

- Eco-friendly and cost-efficient fake marble sheet alternatives are gaining traction, particularly among hospitality, health care, and retail fit-outs.

- Flex marble sheet and flex PVC marble panels are enabling innovative curved and complex installations.

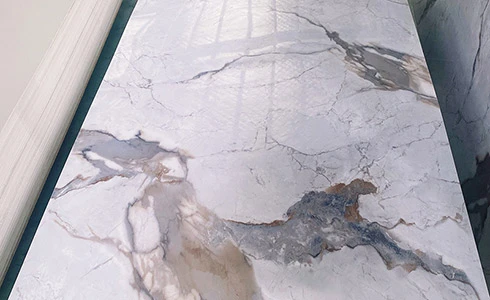

- Emergence of high-definition printing, advanced surface textures (satin, high gloss), and improved anti-fungal properties.

| Specification | Artificial Marble Sheet | Natural Marble | Other Plastics Panels |

|---|---|---|---|

| Thickness | 2mm, 3mm, 4mm, 6mm, 8mm | 20mm, 30mm | 1mm — 12mm |

| Sheet Size | 1220×2440mm, 1560×3050mm, Custom | 600×1200mm, 900×1800mm, Cut-to-size | Standard/Custom |

| Water Absorption | ≤0.05% | ~0.2–0.5% | 0.08–0.2% |

| Bending Radius | Flex: 12–30cm | N/A | Limited |

| Surface Finish | Glossy, Matt, Texture, 3D, Custom | Polished, Honed | Glossy, Matt |

| ISO/ANSI Test Standard | ISO 9001, ANSI/ICPA SS-1 | ISO 14001 | ISO 9001 |

| Lifespan | ≥20 years | 50+ years (susceptible to cracking/staining) | 5–10 years |

| Flame Retardant | Class B1 | Non-flammable | Varies |

| Price Range | $9–$25/m2 | $65–$170/m2 | $5–$20/m2 |

(PVC Resin, Calcium Powder, Stabilizer, Pigments)

(Advanced twin-screw extruder or casting line)

(UV film, Decorative layer, Protective coating)

(Computerized edge trimming, custom shaping)

(ISO 9001 QC, fire/flame test, gloss, adhesion test)

- PVC Core: Polyvinyl chloride (PVC) provides the structural base, resistant to moisture and chemicals.

- Decorative Layer: Colorful high-res print mimics natural stone; available in classic, modern, and bedroom PVC marble sheet designs.

- UV Protective Layer: Prevents fading and increases scratch resistance.

- CNC Machining: Ensures precise dimensions and seamless joinery, simplifying installation even with flex marble sheet types.

| Parameter | PVC Marble Sheet (Artificial Marble Sheet) |

|---|---|

| Thickness | 2mm / 3mm / 4mm / 6mm / 8mm |

| Density | 1.9–2.1 g/cm3 |

| Flexural Strength | 40–60 MPa |

| Bending Radius | 120–300 mm (flex types) |

| Impact Resistance | >3.5 kJ/m2 |

| Flammability | GB/T 8624-2012 B1 (ISO 11925-2, EN 13501-1) |

| Surface Hardness | ≥3H (pencil test) |

| Water Absorption | <0.05% |

| Standard Size | 1220×2440mm, Customizable |

| Surface Options | High Gloss, Matt, Embossed, Metallic, 3D |

- Residential: Walls, ceilings, bedroom PVC marble sheet designs, wardrobes, TV backgrounds, bathrooms.

- Commercial: Shopping malls, hotels, restaurants, hospitals, educational institutions.

- Industrial: Cleanrooms, control rooms, lab equipment enclosures (due to chemical resistance).

- Custom Projects: Flex PVC marble allows for wrap-around counters, columns, arched structures, and bespoke art displays.

- Classic Fake Marble Sheet Trends: Common in quick renovations and budget-sensitive decorative upgrades.

Project: Replacement of natural marble panels in lobbies and guest suites.

Why Artificial: Lightweight (2 area).

Result: Achieved B1-level fire standards, improved acoustic insulation, received 4.7/5 from guests on TripAdvisor for modern style and hygiene.

Chosen for anti-microbial, anti-mildew, non-toxic properties (FDA certified). No VOC emissions. Maintains color and gloss after 1500+ cleaning cycles. Reduced shutdown time by 50% compared with natural stone refurbishment.

“Flexible installation of artificial marble sheet made complex column wrapping feasible. Zero visible joints—clients and tenants impressed!”

| Company | Location | Major Certifications | Main Products | MOQ | Delivery Leadtime |

|---|---|---|---|---|---|

| Sothink Decor | China | ISO 9001, SGS, CE | PVC Marble Sheet, Flex Marble Sheet | 150 sheets | 7-15 working days |

| Alstone | India | ISO 9001, FSC | PVC Laminated Panels, Artificial Marble Board | 100 sheets | 15-22 working days |

| Profine Group | Germany | ISO 14001, EPD | PVC Panels, Laminated Sheet | 200 sheets | 20-30 working days |

- Design Customization: Pattern, color, and size per order; deep-embossed, 3D or metallic surface for premium projects

- Surface Protection: Add UV or anti-bacterial layers depending on installation location

- Bespoke Shaping: CNC finishing for arched, curved, or irregular surfaces, supporting flex marble sheet solutions

- Accessory Matching: Integrated trims, end-caps, and adhesives for seamless finish

- Fast Prototyping: 7-10 day sample delivery by most market leaders

- OEM/ODM Services: Logo printing, packaging customization, export certifications (SGS, BV, Intertek)

(Residential 52%, Commercial 36%, Industrial 12%)

- Lead Time: Standard sheets ship within 7-15 working days after confirmation; custom projects vary with complexity.

- Warranty: Product warranty covers defects, color fastness, and core integrity for up to 10 years.

- Quality Certification: Each batch tested for ISO 9001 quality, EN 13501 fire, and surface hardness before shipment.

- Support: 24/7 online assistance, technical consultation, and on-site team for large-scale installations.

- Packaging: Shock-proof, moisture-resistant, export-grade packaging.

-

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >Mar 17 2025

-

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >Mar 13 2025

-

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >Mar 13 2025

-

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >Mar 13 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com