SPC Flooring Wholesale - Durable & Affordable Composite Core Click Flooring

Jul . 29, 2025 11:00

Explore the latest industry trends, technical specifications, and comparative analysis of spc flooring wholesale, including key factors for specification, sourcing, and custom solutions. With the global composite stone flooring market projected to grow at an impressive CAGR of 6.2% from 2023 to 2028 (Source: MarketsandMarkets), now is the optimal moment to optimize your procurement strategy.

1. Global Market Trends in SPC Flooring Wholesale

The spc flooring wholesale market is experiencing rapid expansion due to urbanization, commercial renovation, and environmental policies. Leading demand drivers include the hospitality, healthcare, and educational sectors, with bulk buyers seeking durability, customization, and minimal VOC standards.

Key 2023–2024 Statistical Highlights:

Key 2023–2024 Statistical Highlights:

- Annual global market size (2023): $4.8 Billion

- Estimated CAGR (2023–2028): 6.2%

- Top wholesalers by volume: USA, Germany, China

- Most requested specification: 4-6mm thickness, EIR surface, click-lock installation

2. Comprehensive Technical Overview of SPC Flooring

Stone Plastic Composite (SPC) flooring, a type of composite core click flooring, features a high-density core composed of calcium carbonate (limestone powder), polyvinyl chloride (PVC), and stabilizers. Its layered technology ensures top-level resilience for heavy-traffic environments.

Structure Layers (from top to bottom):

- UV Coating: Advanced scratch, stain, and fade resistance.

- Wear Layer: 0.3–0.7 mm transparent layer protects patterns.

- Decorative Film: Realistic wood/stone designs via digital print.

- SPC Core: Rigid core with stone-polymer blend for strength.

- IXPE/EVA Foam: Acoustic absorption, added comfort, optional.

| Specification | SPC Flooring | WPC Flooring | Laminate |

|---|---|---|---|

| Core Material | Stone Polymeric Composite | Wood Plastic Composite | HDF Board |

| Waterproof | 100% | 95% | ✘ |

| Dimensional Stability | Excellent | Good | Average |

| Fire Resistance | B1 (EN 13501-1) | B1 | Cfl-s1/B1 |

| Wear Layer Thickness | 0.3-0.7mm | 0.3-0.5mm | 0.2-0.4mm |

| Acoustic Properties | High (IXPE/EVA) | Medium | Low |

| Installation | Click-Lock | Click-Lock | Lock/Glue |

| Formaldehyde | None (FloorScore/ISO) | Low | Medium |

| Applications | Commercial/Residential | Residential | Residential |

Key Performance Index:

Flexural Strength: ≥ 15 MPa (ISO 178)

Dimensional Stability: ≤ 0.06% (EN ISO 23999)

Impact Resistance: ≥ 2000mm (ISO 24335)

Slip Resistance: R10–R12 (DIN 51130/EN 13893)

Fire Rating: B1 (EN 13501-1) - Flame retardant

Eco Certification: FloorScore, CE, ISO 9001, ISO 14001

3. SPC Flooring Wholesale Manufacturing Process Flow

SPC Flooring Production Process:

Below is a flowchart illustrating the end-to-end manufacturing workflow for spc flooring wholesale products in modern facilities:

Notes:

Below is a flowchart illustrating the end-to-end manufacturing workflow for spc flooring wholesale products in modern facilities:

- Raw materials—calcium carbonate, PVC resin, stabilizers—are accurately blended to AAA standards.

- Latest generation extrusion lines and high-precision CNC profiling ensure perfect tongue-and-groove for composite core click flooring systems.

- UV-curing and quality control processes conform to ISO 9001/14001, ASTM F3261, and EN standards.

| Manufacturing Step | Key Equipment | Certification | Quality Control |

|---|---|---|---|

| Raw Material Blending | Precision Mixer | ISO 9001 | Material Ratio Check |

| Extrusion | Twin-Screw Extruder | CE, ANSI | Continuity/Thickness |

| CNC Profiling | Profiling Machine | EN 16511 | Lock System Accuracy |

| UV Coating | Roller, UV Curing | B1 Fireproof, FloorScore | Surface Hardness Test |

| Packing & Inspection | Automated Line | ISO 14001 | Sampling / Full Inspection |

4. Technology Advantages of SPC Flooring Wholesale Versus Major Alternatives

- Dimensional Stability: Rigid core prevents warping/swelling under humidity (tested: <0.07% expansion, SGS 2023).

- Installation: Click-lock channel reduces labor cost by 30–55% versus glue/floating floors.

- Wear Resistance: Passes 20,000 taber revolutions (EN 13329 AC4–AC5).

- Environmental: 100% formaldehyde-free; compatible with underfloor heating up to 80°C.

- Maintenance: Chemical- and stain-resistant; suitable for harsh cleaning protocols (ASTM D4060).

5. SPC Flooring Wholesale Supplier Comparison (2024 Edition)

| Supplier | Main Product | Click System | Certifications | MOQ | Warranty | Lead Time |

|---|---|---|---|---|---|---|

| Sothink Decor | SPC Flooring | UNICLIC 4-side | ISO, FloorScore, CE | 1000 sqm | 20 Years | 15-30 days |

| Tarkett | SPC Click | 2G Clic | Floorscore, ISO | 500 sqm | 15 Years | 30-45 days |

| Shaw Floors | SPC Core Plus | Fold Down | CRI Green, ANSI | 2000 sqm | Lifetime | 25-40 days |

| Armstrong | Rigid Core | Valinge 2G | EN, ISO | 1000 sqm | 10 Years | 20-30 days |

Note: Choose suppliers with third-party certified products (ISO/FloorScore), transparent warranty policies, and a minimum 10-year service record for optimal risk control.

6. Customization & Value-added Solutions for Distributors

Sothink Decor offers flexible spc flooring wholesale customization including:

- Thickness: 3.5mm, 4.0mm, 5.0mm, 6.0mm

- Wear layer: 0.3/0.5/0.7mm

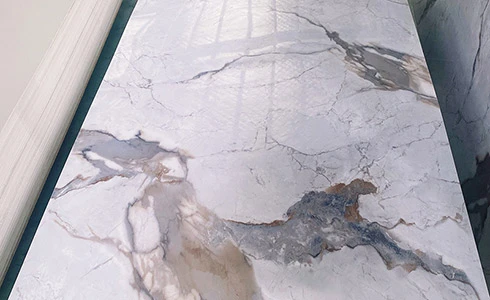

- Surface finish: Embossed-in-Register (EIR), crystal, hand-scraped, high-gloss

- Sizes: 6"x36", 7"x48", 9"x60", custom available

- Acoustic layer: IXPE/EVA (1.0–2.0mm)

- Print design: 280+ wood & stone patterns or OEM artwork

- Antibacterial or ESD coatings upon request

OEM/ODM service: Personalized packaging, barcoding, and marketing support included.

Logistics: Support for DDP, FOB, EXW terms; worldwide shipping integration via Maersk/MSC.

Logistics: Support for DDP, FOB, EXW terms; worldwide shipping integration via Maersk/MSC.

7. Application Scenarios & Selected Project Cases

- Hotels & Resorts: Adopted for lobbies, ballrooms, and suites due to high-traffic resilience.

- Hospitals & Clinics: Hygienic, seamless, easy-to-disinfect composite stone flooring for corridors and wards.

- Schools & Educational Facilities: Durable, anti-slip, and safe for classrooms/hallways (research shows 21% improved slip safety).

- Retail & Commercial Stores: Fast installation, extreme wear for showcase/checkout zones.

- Residential: Kitchens, bathrooms, basements—no water damage even under flooding (tested via ISO 4760 method).

Renovation: 4-Star Hotel, Munich

Product: 5.5mm SPC, EIR finishScope: 3700 sqm, ballrooms/lobbies

Performance: 25% lower maintenance vs wood

Retail Chain: Automotive Showrooms, USA

Product: 6mm SPC, anti-slipScope: 18 stores (average 950 sqm)

Result: Maintains shine under vehicle/foot traffic

Feedback consistently lists spc flooring wholesale for dramatically cutting cost of ownership and standing up to rigorous cleaning and foot traffic—see testimonial data on FloorCovering Weekly.

8. SPC Flooring Technical Parameters Table

| Property | Value | Method |

|---|---|---|

| Thickness | 3.5mm – 6.5mm | Digital Caliper |

| Wear Layer | 0.3–0.7mm | Gravimetric/Optical |

| Density | 1950–2150 kg/m³ | ISO 1183-1 |

| Dimensional Stability | <0.06% | EN ISO 23999 |

| Residual Indentation | <0.08 mm | EN 433 |

| Slip Resistance | R10–R12 | DIN 51130 |

| Fire Resistance | B1 | EN 13501-1 |

| VOC Emission | <0.005 mg/m³ | ISO 16000-9 |

Professional FAQ on SPC Flooring

-

Q1: What core material is used in SPC flooring?

SPC flooring features a rigid Stone Plastic Composite core: approximately 50–65% calcium carbonate (limestone), 30–35% PVC, and stabilizers. This dense composite ensures waterproof and improved dimensional stability. -

Q2: What are the common specifications for spc flooring wholesale?

Typical thicknesses are 3.5mm–6.5mm; wear layer 0.3–0.7mm; sizes: 6"x36", 7"x48", 9"x60". All support click-lock edge joint. -

Q3: What installation standards apply?

Composite core click flooring follows ASTM F3261 for rigid core floors, EN 16511 for lock system precision, and mandates subfloor moisture & flatness checks. -

Q4: How long is the warranty period and what are support terms?

For wholesale contracts, standard commercial warranty is 10–20 years. End-to-end shipping, tech support, and product liability insurance are included. -

Q5: How does SPC compare to traditional vinyl or laminate?

SPC flooring is fully waterproof, more stable against temperature or humidity shifts, and offers higher fire rating (B1 vs lower). It's more rigid than classic LVT, and more scratch-resistant than most laminates due to the dense core and tough wear layer. -

Q6: Are there environmental or health certifications?

Yes, quality spc flooring for sale carries FloorScore, ISO 14001, CE, and low-VOC certifications (in compliance with UL Greenguard or equivalent). -

Q7: What is the usual delivery time and how is quality ensured?

For most spc flooring wholesale orders, lead time is 15–30 days subject to contract volume. Each batch undergoes ISO/EN random sampling, full-thickness check, and joint click-fit test before shipment.

9. Order Delivery, Warranty & Trust

Typical Lead Time: 15–30 days from order.

Warranty: 10–25 years for residential/commercial use, with documentation.

Support: Free product samples, installation guidance (onsite/video), aftersales hotline, compensation for non-conforming batches per ISO/EN contracts.

Certifications: Each batch accompanied by ISO, EN, FloorScore, and fire rating/CPC inspection reports.

Authorized Partners

Warranty: 10–25 years for residential/commercial use, with documentation.

Support: Free product samples, installation guidance (onsite/video), aftersales hotline, compensation for non-conforming batches per ISO/EN contracts.

Certifications: Each batch accompanied by ISO, EN, FloorScore, and fire rating/CPC inspection reports.

Authorized Partners

-

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >Mar 17 2025

-

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >Mar 13 2025

-

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >Mar 13 2025

-

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >Mar 13 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com