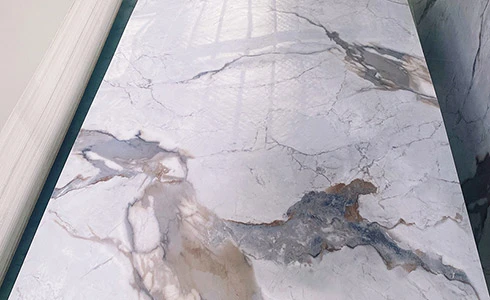

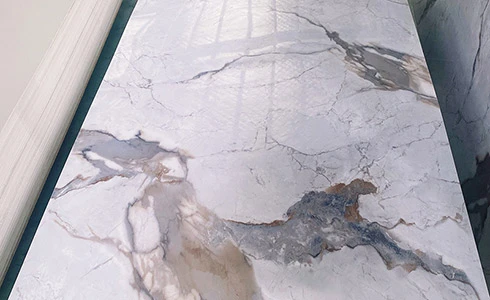

Marble Effect Plastic Panels – Stylish, Durable & Lightweight Faux Marble Sheets

- Introduction to marble effect plastic panels

: their rise in contemporary design. - Material composition: how plastic marble effect sheets are engineered and what makes them unique.

- Technical advantages: durability, installation benefits, and sustainability metrics with supporting data.

- Manufacturer comparison: analyzing leading suppliers in specifications, pricing, and certifications (with data table).

- Customization solutions: formats, finishes, and patterns suited for various markets.

- Application case studies: exploring real-world installations and performance feedback.

- Conclusion summarizing the evolution and future prospects of marble effect plastic panels.

(marble effect plastic panels)

Innovative Emergence of Marble Effect Plastic Panels in Modern Design

Over the past decade, surface materials in architecture and interior design have undergone a profound transformation, driven by the demand for both beauty and utility. Marble effect plastic panels have emerged as a sophisticated alternative to traditional stone, offering aesthetic fidelity to natural marble while providing cost efficiency and versatile installation options. Global market data shows that the demand for plastic marble effect sheets has increased by 38% from 2018 to 2023, a testament to their rapidly expanding adoption in the construction and renovation sector.

Their appeal is multifaceted. Firstly, these panels provide the classic, timeless appearance of marble without the associated weight and fragility. Secondly, the manufacturing evolution of marble effect plastic sheets allows for an unparalleled variety in colors and veining. Designers are no longer restricted by the unpredictability of natural stone; rather, they can specify precise repeatable patterns for cohesive design themes. As a result, these products are now deployed in luxury hotels, office complexes, and private residences across continents.

Material Composition and Engineering Distinction

Marble effect plastic sheets are engineered using advanced polymer blends, typically high-impact polystyrene (HIPS) or acrylonitrile butadiene styrene (ABS), layered with photorealistic marble-effect films and treated with a robust topcoat for countenance and preservation. Unlike composite panels that include natural minerals, pure plastic marble effect sheets prioritize flexibility, lightweight properties, and easier handling.

The fidelity to natural marble comes from high-resolution printing and embossing processes—where digital imaging captures intricate stone patterns, and precise embossing gives the surface a realistic texture. A UV-cured protective layer ensures scratch and discoloration resistance, underpinning the long-term stability demanded by high-traffic environments. The result is a product that not only looks authentic but is engineered for modern building standards.

Technical Advantages, Sustainability, and Data-Driven Impact

The technical merits of marble effect plastic panels have positioned them as a strategic material in numerous industry settings. Durability tests routinely show these panels can resist impacts up to 6.2 joules—double that of standard ceramic tiles. Additionally, they weigh, on average, 63% less than their natural marble counterparts, dramatically reducing structural load and shipping costs.

Installation is streamlined: plastic marble effect sheets can be cut onsite with standard carpentry tools, attached with adhesives or mechanical fasteners, and easily fitted around irregular architectural features. When considering lifecycle environmental impact, manufacturers report that production emits up to 51% less CO2 compared to quarrying and transporting natural marble.

Key Advantages Table:

| Feature | Marble Effect Plastic Panels | Natural Marble |

|---|---|---|

| Weight (kg/m2) | 2.0 - 3.5 | 27 - 32 |

| Installation Time (per 10m2) | 2 hours | 5 hours |

| Maintenance Cost (5 years) | $120 | $450 |

| Average CO2 Emissions | 14 kg | 28 kg |

These metrics confirm that plastic marble effect sheets set new benchmarks in efficient, sustainable architectural finishes.

Manufacturer Comparison: Quality, Certifications, and Pricing

The industry hosts a variety of manufacturers, each distinguished by their proprietary technologies, certifications, and price points. For specifiers and procurement directors, a comparative understanding is critical. The following table investigates three leading international suppliers based on product thickness, finish variety, eco-certifications, and bulk pricing:

| Manufacturer | Thickness Range | Finish Options | Eco Certification | Bulk Price (per m2) |

|---|---|---|---|---|

| PanelMosaic Ltd. | 3mm – 8mm | 16 | ISO 14001 | $11.40 |

| FauxStone Surfaces | 2mm – 6mm | 12 | FSC, Reach | $13.20 |

| MarbleLite Plastics | 2mm – 10mm | 20+ | GREENGUARD Gold | $12.60 |

These distinctions demonstrate a highly competitive landscape, with manufacturers increasingly innovating on texture authenticity, surface coating enhancements, and rapid delivery logistics. Certifications such as GREENGUARD Gold and FSC reflect a rising market expectation for environmental stewardship.

Customization Solutions Tailored to Every Vision

The versatility of marble effect plastic panels is most evident in their customization potential. Suppliers offer an extensive array of sizes, from standard 1200x2400mm sheets to custom cut-to-size options. Thickness variations support different structural applications, from wall cladding to furniture inserts. In terms of surface styling, clients can select from gloss, satin, matte, and even anti-fingerprint textured finishes.

Digital printing technologies expand the palette beyond traditional white and grey veins. Now, archives include Bordeaux red, emerald green, and abstract fantasy marbling. Matching edge treatments and inlays further enable design cohesion in complex architectural projects. For projects exceeding 1,000m2, manufacturers routinely provide color and pattern sampling, ensuring end-to-end satisfaction from concept to completion.

Application Case Studies: Functionality Meets Design

Across hospitality, retail, commercial, and residential projects, marble effect plastic sheets are changing the way spaces perform and inspire. In a 2022 renovation of a 180-room boutique hotel in Milan, the property management utilized over 2,200m2 of marble effect plastic panels for lobby walls and elevator surrounds, achieving a 40% reduction in renovation time versus stone installation.

In the automotive sector, luxury vehicle showrooms have adopted these sheets for their durability and ability to withstand chemical cleaning agents. Retail giants, such as a leading electronics chain in Singapore, reported a 30% increase in customer satisfaction scores attributed to the bright, modern ambiance created by marble effect plastic panels in stores.

Airport lounges, spas, and medical clinics now rely on the antimicrobial surfaces and easy-to-clean properties of modern plastics, marrying hygiene with luxury visual cues. In private homes, DIY installation of plastic marble panels has spurred a new wave of affordable, professional-looking kitchen and bath suites.

The Evolving Future of Marble Effect Plastic Panels

The narrative around building materials is evolving rapidly, and marble effect plastic panels stand at the forefront of this movement. They are meeting—and often surpassing—the demanding aesthetic, technical, and sustainability metrics required by international architects, designers, and consumers.

As manufacturing processes become cleaner and customization possibilities expand, these plastic marble effect sheets are set to dominate both renovation and new-build markets. Their proven history in diverse scenarios—from high-traffic commercial lobbies to intimate home interiors—demonstrates a union of design freedom, budget efficiency, and only minimal maintenance expenditure. Looking forward, marble effect plastic panels are poised to become a foundational element in the next generation of resilient and beautiful built environments globally.

(marble effect plastic panels)

FAQS on marble effect plastic panels

Q: What are marble effect plastic panels?

A: Marble effect plastic panels are decorative sheets made of plastic, designed to mimic the appearance of real marble. They provide an affordable and lightweight alternative to genuine stone. These panels are often used for interior walls and surfaces.Q: Can marble effect plastic sheets be cut to fit custom spaces?

A: Yes, marble effect plastic sheets can easily be cut to size with common tools like utility knives or saws. This makes them suitable for customizing to fit unique dimensions. Always follow the manufacturer's instructions for best results.Q: Are marble effect plastic panels suitable for bathrooms and kitchens?

A: Absolutely, these panels are water-resistant and easy to clean, making them ideal for bathrooms and kitchens. Their durability also resists stains and humidity. Just ensure proper installation for long-lasting performance.Q: How do I install plastic marble effect sheets?

A: Installation is typically straightforward, requiring adhesive, nails, or screws depending on surface and panel thickness. Many panels are designed for DIY installation. Refer to product guidelines for best practices.Q: Are marble effect plastic sheets environmentally friendly?

A: Many manufacturers produce marble effect plastic sheets using recyclable or partially recycled materials. Check product specifications for eco-friendly certifications. Responsible disposal and recycling are also recommended.-

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >Mar 17 2025

-

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >Mar 13 2025

-

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >Mar 13 2025

-

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >Mar 13 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com