Modern PVC Ceiling Board Design Ideas for Stylish Interiors Durable & Easy Installation

- Introduction to the market and significance of pvc ceiling board design

- Material innovations and technical advantages of pvc ceiling boards

- Vendor and product comparison with key specifications table

- Popular pvc board ceiling design trends and aesthetic strategies

- Custom solutions and considerations for specific environments

- Real-world application cases: Residential, commercial, institutional

- Conclusion: The evolving role of ceiling board design in modern spaces

(pvc ceiling board design)

Introduction to the Market and Significance of PVC Ceiling Board Design

The global construction industry has embraced pvc ceiling board design as a pivotal element in both residential and commercial interiors. The demand for functional and aesthetically pleasing ceiling finishes has grown rapidly, with the US, Southeast Asia, and the Middle East driving a market forecasted to reach USD 2.1 billion by 2027, growing at a CAGR of 6.4%. PVC, or polyvinyl chloride, ceiling boards have revolutionized traditional ceiling options due to their high durability, water resistance, and cost-effectiveness. Their lightweight structure and flexible design possibilities offer architects and interior designers an unprecedented scope to redefine overhead spaces. Moreover, sustainability trends push manufacturers to improve the recyclability and eco-friendliness of their boards, aligning their offerings with modern environmental standards. The surge in smart homes, acoustically engineered environments, and modular office spaces positions pvc ceiling board design as a core architectural feature for decades to come.

Material Innovations and Technical Advantages

Technological advancements distinguish contemporary PVC ceiling boards from earlier materials. Modern ceiling board designs are manufactured with advanced co-extrusion techniques, enhancing resistance to humidity, fire, and microbial growth. Comparative lab tests reveal that PVC ceiling panels offer 35% higher resistance to moisture than gypsum boards and maintain structural integrity at temperatures up to 60°C. Their surface coatings employ nanotechnology to repel dust, thereby reducing maintenance frequency by up to 50%. Furthermore, the acoustic performance of premium PVC boards, registering a Sound Transmission Class (STC) rating of 29-31, demonstrates superior noise reduction compared to conventional alternatives. Innovations such as click-lock installation systems reduce onsite labor by over 40%, enabling faster project turnovers. These advantages position PVC as a material of choice for ceiling board design that must meet stringent technical requirements without compromising visual appeal.

Vendor and Product Comparison with Key Specifications Table

The variety in ceiling board design options extends across brands and providers. Leading PCV board vendors compete by offering unique blends of durability, finish, size, and environmental attributes. Below is a comparative table highlighting key technical and aesthetic aspects from prominent manufacturers in the global market:

| Vendor | Max Size (mm) | Finish Options | Fire Rating | Moisture Resistance | Warranty | Environmental Certifications |

|---|---|---|---|---|---|---|

| Royal Decor Panels | 600 X 600 | Glossy, Matte, Wooden | B1 | High (ISO 6270-2) | 10 Years | CE, RoHS |

| Decorative Ceiling Systems | 250 X 4000 | Laminated, Metallic | B2 | Moderate | 7 Years | EcoLabel, REACH |

| Everest Plastics | 300 X 3000 | Textured, Plain | B1 | High | 12 Years | FSC, Greenpro |

| CEILICO Solutions | 200 X 6000 | 3D, Metallic, Wood Grain | A2 | Very High | 15 Years | ISO 14001 |

Product decisions should be guided by a balanced consideration of fire rating, sustainability certifications, finish diversity, and warranty period. The above vendors demonstrate leadership in combining technical robustness and compliant design innovations.

Current PVC Board Ceiling Design Trends and Aesthetic Strategies

The sophistication of pvc board ceiling design has grown beyond utilitarian function to embrace decorative versatility. Minimalist and geometric patterns dominate new builds, reflecting demand for clean, contemporary interiors. Hybrid installations combining recessed lighting and 3D ceiling arrays have gained traction in luxury hospitality and entertainment venues. Faux wood finishes using advanced photo-lamination processes create the illusion of natural timber without the associated maintenance or environmental impact. Color varieties have expanded, with over 38 shades now readily available, opening creative potential for customized interiors.

Patterned tiles, perforated motifs for acoustic enhancement, and concealed indirect illumination via cove-mountable PVC profiles are highly sought after by architects and project managers. Ceiling board design today balances aesthetic values with practical integration into HVAC, lighting, and automated systems. The rise of biophilic design, inspired by organic forms and natural materials, is leading to softer curves, leaf textures, and softly reflective surfaces in PVC ceiling products.

Custom Solutions and Considerations for Specific Environments

Customization is a defining characteristic of premium ceiling board design. Detailed client consultations are employed to specify dimensional tolerances, installation logistics, integrated lighting requirements, and brand-compliant color matching. In high-humidity environments such as spas and kitchens, closed-cell PVC boards with anti-fungal treatments are specified to prevent mold outbreaks, reflecting a 30% reduction in wall and ceiling refurbishments over five years compared to untreated products.

Healthcare facilities require boards with antimicrobial coatings and low volatile organic compound (VOC) emissions, supporting cleaner air and patient safety. In transport hubs and retail stores, impact-resistant PVC panels are selected to manage accidental knocks and ease ongoing cleaning. Manufacturers collaborate closely with architects to create perforated panels that optimize acoustic comfort in cinemas, lecture halls, and auditoriums. Incorporating branding, signage recesses, and dramatic lighting integrations further individualizes ceiling board design for commercial environments.

For residential clients, bespoke domed ceilings, tray designs, and multilevel arrangements are increasingly popular. Digital printing and laser-cutting technologies allow for the seamless translation of complex artistic visions into functional, manufacturable elements.

Real-world Application Cases: Residential, Commercial, and Institutional

Multiple case studies exemplify the adaptability of pvc ceiling board design. In residential apartments in Southeast Asia, PVC boards reduced installation times by 40% compared to traditional plaster, saving costs and minimizing tenant disruption. Projects such as the Rosewood Hotel in Dubai deployed high-gloss gold-toned PVC ceiling tiles alongside fiber optic lighting, creating a striking luxury guest experience with minimal ongoing maintenance.

In schools and universities, high STC-rated PVC boards achieved a 5dB reduction in classroom noise levels, facilitating improved learning environments. Healthcare clinics in Scandinavia utilized antimicrobial-finished PVC to exceed national infection control guidelines while maintaining comforting, clean aesthetics. Retail giants in North America modernized over 40,000 square meters of ceiling in flagship stores, achieving both LEED certification and dramatic seasonal rebranding via interchangeable printed panels. Such examples underline ceiling board design's impact on functionality, brand identity, and long-term facility management.

Conclusion: The Evolving Role of Ceiling Board Design in Modern Spaces

As architecture continues to prioritize flexibility, wellness, and energy efficiency, ceiling board design with PVC materials is set to play a foundational role in 21st-century interiors. Its unparalleled blend of technological sophistication, customizability, and cost efficiency answers the diverse demands of residential, commercial, and institutional markets. With ongoing innovations in material composition and installation techniques, PVC ceiling boards ensure architects, designers, and property owners remain well-equipped to shape functional and visually compelling environments. The competitive landscape fosters further development, guaranteeing that this ubiquitous material will continue to adapt to the evolving challenges of global construction and interior trends.

(pvc ceiling board design)

FAQS on pvc ceiling board design

Q: What are the latest trends in PVC ceiling board design?

A: Trending PVC ceiling board designs include 3D geometric patterns, wood-grain textures, and integrated LED lighting. These styles add modern and elegant touches to interiors. Minimalist and easy-to-clean designs are also popular in contemporary spaces.Q: Can PVC board ceiling designs be customized for different room shapes?

A: Yes, PVC board ceiling designs can be tailored to fit various room shapes and sizes. Custom panels can be cut and arranged for unique layouts. This flexibility makes them suitable for any residential or commercial project.Q: What are the main benefits of using PVC ceiling boards for ceiling board design?

A: PVC ceiling boards are lightweight, water-resistant, and easy to install. Their durability and low-maintenance requirements make them ideal for both homes and businesses. They also come in a wide range of colors and patterns.Q: Are PVC ceiling board designs suitable for humid areas?

A: Absolutely, PVC ceiling boards are moisture-resistant and perfect for bathrooms, kitchens, and basements. They prevent mold and mildew buildup. This makes them reliable for high-humidity environments.Q: How do I maintain and clean my PVC board ceiling design?

A: Cleaning PVC board ceiling designs is simple—just wipe them with a damp cloth and mild detergent. They do not require painting or polishing. Regular dusting will help maintain their fresh appearance.-

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >Mar 17 2025

-

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >Mar 13 2025

-

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >Mar 13 2025

-

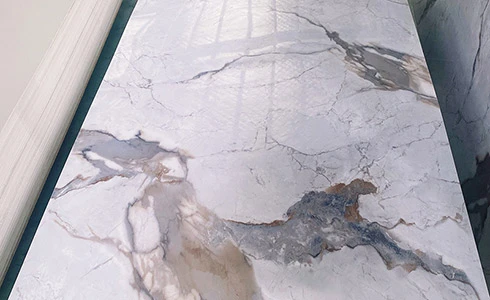

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >Mar 13 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com