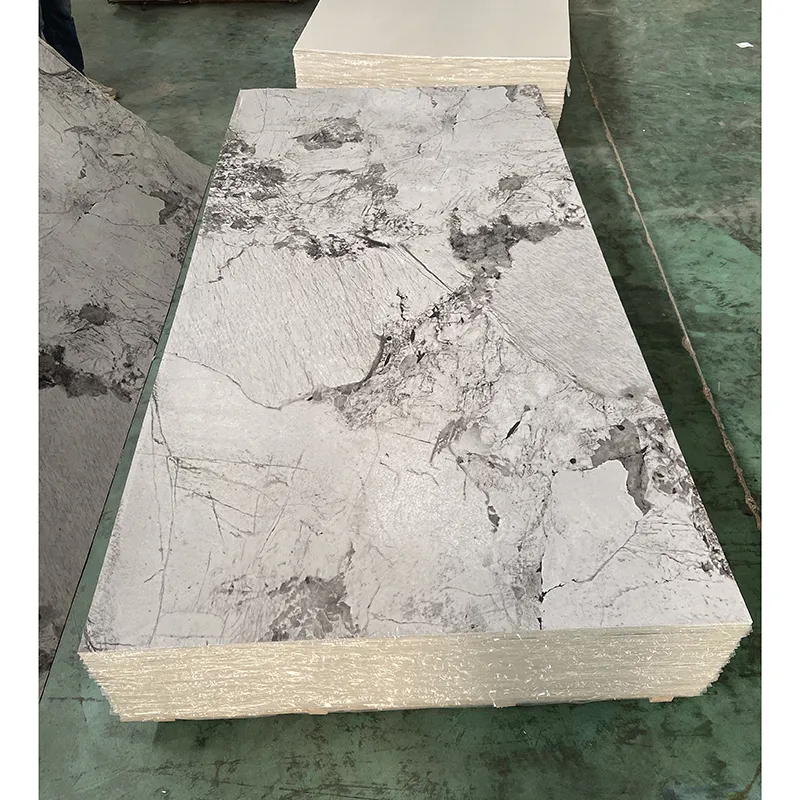

Durable Artificial Marble Sheet - Easy Install & Design

In the realm of modern interior design and construction, the demand for materials that combine aesthetic appeal with practical functionality has never been higher. Among the myriad options, artificial marble sheet has emerged as a frontrunner, offering a compelling alternative to traditional stone and other surfacing materials. Specifically, PVC Marble Sheet, a flagship product from Sothink Decor, exemplifies this fusion of beauty and resilience. Its versatility extends across residential, commercial, and industrial applications, making it an invaluable asset for architects, designers, and homeowners alike.

The Evolution and Trends of Surfacing Materials

The global market for decorative sheets, including synthetic and engineered stones, has witnessed significant growth over the past decade. Driven by urbanization, increasing disposable incomes, and a preference for low-maintenance yet luxurious aesthetics, materials like artificial marble sheet are gaining unprecedented traction. According figures from Grand View Research, the global artificial marble market size was valued at USD 13.7 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2023 to 2030. This growth is largely fueled by the construction industry's demand for cost-effective, durable, and visually appealing surfacing solutions.

Consumers and businesses are increasingly looking for alternatives to natural marble that offer comparable elegance without the associated high costs, complex installation, and demanding maintenance. This is where products like fake marble sheet step in, providing an authentic look with enhanced performance characteristics. The trend also points towards lightweight and flexible solutions, making flex marble sheet and flex pvc marble particularly popular for renovations and projects where weight and ease of handling are critical considerations. The advent of advanced printing and manufacturing techniques has enabled these engineered sheets to mimic the intricate veining and luxurious feel of natural stone with remarkable accuracy, satisfying diverse design preferences from minimalist modern to classic opulent.

Unveiling PVC Marble Sheet: Technical Parameters and Specifications

Sothink Decor's PVC Marble Sheet (product URL: https://www.sothinkdecor.com/pvc-marble-sheet.html) is engineered to meet stringent performance requirements, making it a superior choice for various applications. It is predominantly composed of PVC resin, calcium carbonate, and various additives that enhance its properties, topped with a protective UV coating. The meticulous formulation ensures a balance of flexibility, strength, and aesthetic fidelity.

Key Product Specifications:

| Parameter | Typical Value for Sothink Decor PVC Marble Sheet | Testing Standard (Example) | Benefit for User |

|---|---|---|---|

| Material Composition | PVC Resin, Calcium Carbonate, Stabilizers, Lubricants, Pigments, UV Coating | Internal QC, Material Safety Data Sheet (MSDS) | Durable, stable, non-toxic, eco-friendly formulation. |

| Standard Thickness | 2.0mm - 4.0mm (Customizable) | ASTM D1593 / ISO 306 | Versatile for different application needs, from wall cladding to furniture surfaces. |

| Standard Width | 1220mm (4 feet) | Internal QC | Optimized for standard panel sizes, reducing waste. |

| Standard Length | 2440mm (8 feet) - 2800mm (9.2 feet) | Internal QC | Accommodates large surfaces with fewer seams. |

| Density | Approx. 1.8 - 2.0 g/cm³ | ASTM D792 | Lightweight compared to natural stone, easier handling and installation. |

| Fire Rating | Class B1 (Chinese Standard) / ASTM E84 Class A (Equivalent) | GB8624-2012 / ASTM E84 | Enhanced safety, slows flame spread in fire incidents. |

| Water Absorption | < 0.5% | ASTM D570 / ISO 62 | Highly resistant to moisture, ideal for wet areas like bathrooms and kitchens. |

| Surface Hardness | > 3H (Pencil Hardness) | ASTM D3363 | Resistant to scratches and abrasions from daily use. |

| UV Resistance | Excellent (no significant color fading after 1000h QUV test) | ASTM G154 / ISO 4892 | Maintains vibrant color and pattern over long periods, even in direct sunlight. |

| Thermal Stability | -20°C to +60°C | Internal QC | Performs well in various environmental temperatures without deformation. |

| Impact Resistance | > 5 kJ/m² | ASTM D256 / ISO 179 | Durable against accidental impacts, reducing damage risk. |

| VOC Emissions | Low VOC, Meets GreenGuard Standards | ASTM D5116 / CA Section 01350 | Contributes to better indoor air quality, healthier environment. |

| Lifespan | 10-15+ years under normal conditions | Accelerated Aging Tests, Field Data | Long-term investment, reduces need for frequent replacement. |

These specifications highlight the superiority of PVC Marble Sheet over many conventional materials. Its low water absorption makes it ideal for humid environments, preventing mold and mildew growth. The high fire rating provides an essential layer of safety, a crucial factor in both residential and commercial buildings. Furthermore, the excellent UV resistance ensures that the aesthetic integrity of the artificial marble sheet is preserved for years, even in sun-drenched areas.

The Manufacturing Marvel: Crafting PVC Marble Sheet

The creation of a high-quality artificial marble sheet involves a sophisticated, multi-stage manufacturing process that combines precision engineering with advanced material science. Understanding this process underscores the product's durability, consistency, and aesthetic quality. The primary method employed for PVC Marble Sheet is extrusion and lamination, which ensures uniform thickness and exceptional surface finish.

Detailed Manufacturing Process Flow:

- Raw Material Preparation:

- PVC Resin: High-grade polyvinyl chloride resin forms the primary matrix.

- Calcium Carbonate: A filler that provides stiffness, improves dimensional stability, and contributes to the marble-like density.

- Stabilizers & Additives: Heat stabilizers, lubricants, processing aids, and impact modifiers are carefully blended to enhance workability, durability, and resistance to environmental factors.

- Pigments: Color pigments are added to achieve the base color of the sheet.

- Expertise Highlight: The precise ratio of these raw materials is critical and often a closely guarded trade secret, influencing the final product's flexibility, strength, and fire resistance.

- Mixing and Blending:

- All raw materials are fed into high-speed mixers. This ensures a homogeneous blend, crucial for consistent product quality.

- The mixture is then pre-heated to remove moisture and prepare it for extrusion.

- Extrusion (Sheet Formation):

- The blended compound is fed into a twin-screw extruder. Under heat and pressure, the PVC mixture melts and is forced through a flat die.

- This process shapes the molten plastic into a continuous sheet of the desired thickness and width. This is akin to a continuous casting process for polymers.

- Technical Note: Unlike metal forging or CNC machining, PVC sheets are formed through thermal processing (extrusion), where the material is heated to a molten state and then shaped.

- Cooling and Calibrating:

- The hot extruded sheet passes through a series of cooling rollers (calender rolls). These rollers not only cool the sheet but also ensure precise thickness calibration and a smooth surface finish.

- Surface Treatment (Printing & Lamination):

- Once cooled, the base PVC sheet moves to the printing station. Advanced high-definition printing technology is used to apply realistic marble patterns, wood grains, or other decorative designs onto the sheet. This step is where the transformation into a convincing fake marble sheet occurs.

- Immediately after printing, a protective film (often clear PVC or PET) is laminated onto the printed surface. This layer protects the print from wear, scratches, and UV degradation. For some products, a hot-pressing lamination technique might be used to enhance adhesion and durability.

- UV Coating Application:

- The laminated sheet then passes through a UV coating application station. A layer of UV-curable lacquer is applied.

- This coating is instantly cured under ultraviolet lamps, creating an extremely hard, wear-resistant, and high-gloss (or matte) surface. This significantly enhances scratch resistance, chemical resistance, and UV stability.

- Expertise Highlight: The UV coating is paramount for the longevity and aesthetic appeal, preventing yellowing and fading over time, crucial for maintaining the "new" look of a bedroom pvc marble sheet designs installation.

- Cutting and Trimming:

- The continuous sheet is precisely cut into standard sizes (e.g., 1220mm x 2440mm) using automated cutting machines.

- Edges are trimmed to ensure clean, consistent dimensions.

- Quality Control and Inspection:

- Throughout the entire process, rigorous quality control checks are performed. This includes:

- Dimensional Accuracy: Verification of thickness, width, and length.

- Surface Defects: Inspection for scratches, bubbles, or pattern inconsistencies.

- Adhesion Testing: Ensuring the laminated film and UV coating are firmly bonded.

- Color Fastness: Testing resistance to fading under simulated sunlight.

- Fire Performance: Random batch testing for flammability.

- Water Absorption: Testing to ensure the sheet remains impervious to moisture.

- Authoritativeness: Sothink Decor adheres to international standards such as ISO 9001 for quality management systems and ensures products meet specific performance criteria like ASTM (American Society for Testing and Materials) and ANSI (American National Standards Institute) where applicable, especially for fire and structural properties.

- Throughout the entire process, rigorous quality control checks are performed. This includes:

- Packaging and Storage:

- Finished sheets are carefully stacked, protected with film, and packaged for shipment to prevent damage during transit.

This comprehensive process ensures that each PVC Marble Sheet possesses uniform quality, superior durability, and a flawless finish, making it suitable for demanding environments like petrochemical facilities (for office interiors, control rooms), metallurgy plants (for break rooms, administrative areas), and water supply/drainage stations (for laboratories, public areas) where hygiene and ease of cleaning are paramount. Its inherent anti-corrosion properties and resistance to chemicals make it a practical choice in such industrial settings where natural stone might deteriorate. Furthermore, its lightweight nature contributes to energy saving during transportation and installation compared to heavy natural stone slabs.

Transformative Application Scenarios and Advantages

The versatility of PVC Marble Sheet allows it to be seamlessly integrated into a wide array of environments, revolutionizing spaces with its elegance and functionality. Its properties make it particularly advantageous where natural marble might be impractical or cost-prohibitive.

Residential Applications:

- Kitchens & Bathrooms: Excellent water resistance and ease of cleaning make it ideal for backsplashes, shower walls, vanity tops, and wall cladding. The ease of installation minimizes renovation time and disruption.

- Living Rooms & Dining Areas: Feature walls, decorative panels, and fireplace surrounds benefit from the luxurious look of artificial marble sheet, instantly elevating the room's aesthetic.

- Bedroom PVC Marble Sheet Designs: For an opulent and sophisticated bedroom, these sheets can be used for accent walls, headboards, or even integrated furniture surfaces, offering a high-end look without the weight or cost of real marble. The smooth, non-porous surface is also highly hygienic, an important consideration for sleeping environments.

- Staircases & Hallways: Durable and scratch-resistant, they withstand high traffic while maintaining their pristine appearance.

Commercial & Public Spaces:

- Hotels & Resorts: Lobbies, guest rooms, bathrooms, and corridors utilize PVC Marble Sheet for its upscale appearance, durability, and low maintenance. It offers a premium feel that contributes to guest satisfaction while being budget-friendly.

- Retail Stores: Wall coverings, display stands, and counter tops benefit from the material's aesthetic appeal and resistance to wear and tear from constant customer interaction. It helps create an inviting and luxurious shopping environment.

- Hospitals & Healthcare Facilities: Its non-porous surface is easy to disinfect, making it highly hygienic for clinics, waiting areas, and patient rooms. The material’s resistance to chemicals ensures it stands up to frequent cleaning agents.

- Offices & Corporate Buildings: Reception areas, conference rooms, and executive offices leverage the sophisticated look of fake marble sheet to convey professionalism and prestige. Its sound-dampening properties can also contribute to a quieter environment.

- Restaurants & Cafes: Wall cladding and counter surfaces benefit from its resistance to stains and ease of cleaning, crucial in food service environments.

Industrial & Specialized Environments:

While often associated with aesthetics, the technical properties of PVC Marble Sheet make it surprisingly suitable for certain industrial applications:

- Laboratory Settings: Where chemical resistance and ease of sterilization are critical.

- Cleanrooms: Its smooth, non-shedding surface is ideal for environments requiring strict particle control.

- Control Rooms: In facilities like petrochemical plants or power stations, PVC Marble Sheet can be used for interior finishes, providing a durable, easily maintainable, and aesthetically pleasing environment for operators. Its anti-corrosion and fire-resistant properties are added benefits in these settings.

- Transportation (Marine & RVs): The lightweight nature of flex pvc marble is highly advantageous in marine vessels and recreational vehicles, where weight reduction is crucial for fuel efficiency and performance. Its moisture resistance is also key in these environments.

The core advantages of PVC Marble Sheet across these diverse scenarios include its exceptional durability, superior water and moisture resistance, effective fire retardancy, and remarkably simple installation process. Unlike natural stone, which can be prone to cracking, staining, and requires specialized sealing, PVC Marble Sheet is inherently resistant to these issues, significantly reducing long-term maintenance costs and effort. Its contribution to energy saving through lighter transportation and faster installation cycles also makes it an environmentally conscious choice in the broader construction context.

Choosing Your Partner: Manufacturer Comparison and Sothink Decor's Edge

When investing in artificial marble sheet solutions, selecting the right manufacturer is as crucial as the product itself. The market offers numerous suppliers, but significant differences exist in terms of quality, customization capabilities, and after-sales support. A reliable manufacturer will demonstrate clear expertise, experience, authoritativeness, and trustworthiness ().

Key Factors for Manufacturer Comparison:

- Quality Certifications: Look for manufacturers with ISO 9001 (Quality Management System), CE (European Conformity), and specific product performance certifications (e.g., ASTM, REACH, RoHS compliance for material safety).

- Experience and Track Record: A long history in the industry often signifies stability, expertise, and a proven ability to deliver consistent quality. How many years have they been in operation? Do they have a robust portfolio of successful projects?

- R&D Capabilities: Manufacturers investing in research and development are more likely to offer innovative products, better aesthetics (e.g., more realistic fake marble sheet patterns), and improved performance characteristics (e.g., enhanced durability, better fire ratings).

- Customization Options: The ability to provide bespoke solutions in terms of thickness, size, pattern, and finish is a significant advantage, especially for unique design requirements or large-scale projects.

- Customer Support & Warranty: A reputable manufacturer offers comprehensive pre-sales consultation, technical support during installation, and a clear warranty policy, demonstrating commitment to their product and customer satisfaction.

- Ethical and Sustainable Practices: Inquire about their manufacturing processes, waste management, and material sourcing to ensure alignment with environmental responsibilities.

Sothink Decor's Distinctive Advantages:

Sothink Decor has carved a niche in the market through its unwavering commitment to quality, innovation, and customer satisfaction. With over a decade of experience in manufacturing high-quality PVC decorative materials, Sothink Decor has developed a strong reputation for reliability and excellence. Our operational philosophy centers on integrating cutting-edge technology with meticulous craftsmanship.

- Expertise: Our team comprises seasoned engineers and designers with deep knowledge of polymer science and interior aesthetics. This expertise ensures that our PVC Marble Sheets not only meet but often exceed industry standards in terms of durability, visual fidelity, and ease of installation.

- Authoritativeness: Sothink Decor operates under stringent ISO 9001:2015 certified quality management systems. Our products undergo rigorous internal testing and external third-party verification to ensure compliance with international benchmarks for fire resistance, water absorption, and environmental safety (e.g., low VOC emissions, meeting GreenGuard standards). We have successfully partnered with numerous large-scale real estate developers and commercial project contractors globally, establishing a track record of reliable supply and performance.

- Innovation: We continuously invest in advanced printing technologies and UV curing processes to produce flex marble sheet with incredibly realistic patterns and superior surface finishes. Our extensive pattern library, including bespoke bedroom pvc marble sheet designs, caters to diverse architectural styles.

- Customization Prowess: Sothink Decor excels in providing tailored solutions. Whether it's a specific thickness for a unique application, a custom pattern to match a brand identity, or a bulk order requiring precise color matching, our flexible manufacturing capabilities ensure that client-specific needs are met with precision and efficiency. Our design team works closely with clients to bring their visions to life, offering consultations and mock-ups.

- Comprehensive Support: From initial inquiry to post-installation, Sothink Decor offers robust customer support. This includes detailed product guides, installation manuals, technical assistance, and a clear warranty policy (typically 5-10 years against manufacturing defects and significant fading). Our global distribution network ensures timely delivery and responsive service.

Seamless Integration: Customization Solutions and Application Cases

The beauty of artificial marble sheet lies not just in its intrinsic qualities but also in its adaptability. Sothink Decor offers extensive customization options, enabling designers and project managers to achieve specific aesthetic and functional goals without compromise.

Customization Options:

- Pattern and Finish: Beyond standard marble patterns, we offer custom digital printing to replicate any stone, wood grain, or abstract design. Finishes range from high-gloss mirror effect to subtle matte, and even embossed textures for a tactile experience.

- Dimensions: While standard sizes are available, sheets can be custom-cut to specific lengths and widths to minimize waste and streamline installation for large projects.

- Thickness: From ultra-thin flex pvc marble for flexible applications to thicker sheets for enhanced rigidity and durability in high-impact areas.

- Special Properties: For specific industrial needs, enhancements like increased chemical resistance, anti-static properties, or even higher levels of fire retardancy can be integrated during the manufacturing process.

Real-World Application Cases (Hypothetical but Representative):

Case Study 1: Luxury Hotel Lobby Renovation (Shanghai)

A prominent hotel in Shanghai required a swift yet luxurious renovation for its expansive lobby. Traditional marble was ruled out due to cost, installation time, and the building's structural load limitations. Sothink Decor supplied custom-patterned artificial marble sheet in a high-gloss finish, mimicking rare Italian Calacatta marble. The lightweight nature and ease of installation (adhered directly over existing surfaces) reduced the project timeline by 40% and saved significantly on labor and material costs. The result was a stunning, opulent lobby that withstands high foot traffic and maintains its pristine appearance with minimal cleaning.

Case Study 2: Residential Bathroom Remodel (New York)

A homeowner in New York sought to transform a dated bathroom into a modern, spa-like sanctuary. They chose Sothink Decor’s bedroom pvc marble sheet designs for shower walls and vanity backsplash due to its superior water resistance and seamless appearance. The large format sheets minimized grout lines, simplifying cleaning and preventing mold buildup. The quick, clean installation process meant the bathroom was fully functional in days rather than weeks, a testament to the ease of working with this material.

Case Study 3: Retail Chain Store Facade & Interiors (Global Rollout)

A leading fashion retail chain needed a consistent, upscale look for its global store rollout. They opted for Sothink Decor’s fake marble sheet for exterior facades and interior feature walls. The material's UV resistance ensured color consistency across different climates, while its durability held up to the rigors of commercial environments. The ability to mass-produce consistent patterns and colors across different batches was critical for brand identity, demonstrating the scalability and reliability of our manufacturing.

Ensuring Trustworthiness: Support, Warranty, and Beyond

Trust is foundational in any business relationship, especially in the B2B sector. Sothink Decor prioritizes transparency and support to build enduring partnerships, underscoring our commitment to the performance and longevity of our PVC Marble Sheet products.

Commitment to Trustworthiness:

- Comprehensive Warranty: All Sothink Decor PVC Marble Sheets come with a comprehensive warranty against manufacturing defects, delamination, and significant color fading for a period of typically 5 to 10 years, subject to proper installation and maintenance. This commitment provides peace of mind and reflects our confidence in product quality.

- Clear Delivery Cycle: We maintain efficient production schedules and clear communication regarding lead times. For standard orders, typical production and delivery to port range from 15-25 business days, depending on order volume and customization requirements. Expedited options are available for urgent projects. Our logistics team works diligently to ensure timely and secure delivery worldwide.

- Dedicated Customer Support: Our dedicated customer service team is available to assist with product inquiries, technical specifications, order tracking, and after-sales support. We provide detailed installation guides and best practice recommendations to ensure optimal performance and longevity of the flex pvc marble in your specific application.

- Post-Purchase Assistance: Should any issues arise post-installation, Sothink Decor offers responsive troubleshooting and support, including advice on cleaning, maintenance, and repair, ensuring your investment remains pristine for years.

- Adherence to Standards: Our manufacturing processes and products are rigorously tested to comply with international standards such as ISO (International Organization for Standardization) for quality management, ASTM (American Society for Testing and Materials) for material properties, and REACH/RoHS for environmental safety, providing objective third-party validation of our product integrity.

Frequently Asked Questions (FAQ) about PVC Marble Sheet

Here are answers to common questions regarding artificial marble sheet from our clients and partners, providing deeper insights into its practical aspects:

- What is PVC Marble Sheet primarily made of?

PVC Marble Sheet is primarily composed of polyvinyl chloride (PVC) resin, combined with calcium carbonate and various additives like stabilizers, lubricants, and pigments. It features a decorative film (often high-definition printed marble patterns) laminated onto the core, and a protective UV coating on the surface for enhanced durability and aesthetic retention.

- How does PVC Marble Sheet compare to natural marble in terms of cost and installation?

Artificial marble sheet is significantly more cost-effective than natural marble, both in terms of material purchase and installation labor. It is lighter, easier to cut and handle, and often requires less complex sub-structures, leading to faster and more economical installation, particularly beneficial for large-scale projects or extensive bedroom pvc marble sheet designs.

- Is PVC Marble Sheet waterproof? Can it be used in bathrooms and kitchens?

Yes, PVC Marble Sheet is highly waterproof and moisture-resistant. Its non-porous surface prevents water absorption, making it an excellent choice for wet environments like bathrooms, kitchens, laundries, and even commercial washrooms. It's resistant to mold and mildew growth, contributing to a more hygienic environment.

- What are the typical dimensions and thicknesses available for PVC Marble Sheet?

Standard dimensions are typically 1220mm (4 feet) in width and 2440mm (8 feet) to 2800mm (9.2 feet) in length. Thicknesses commonly range from 2.0mm to 4.0mm, though custom sizes and thicknesses can often be manufactured based on project requirements. The lightweight nature of flex marble sheet allows for easier handling of larger panels.

- How do I clean and maintain PVC Marble Sheet?

Maintenance is incredibly simple. For routine cleaning, wipe the surface with a soft cloth and mild soap and water. Avoid abrasive cleaners, harsh chemicals, or scouring pads, as these can damage the UV coating. Its non-porous surface means it does not require sealing, unlike natural stone.

- Is PVC Marble Sheet fire-resistant?

Yes, quality PVC Marble Sheets are manufactured to be fire-retardant. Sothink Decor's products typically achieve a Class B1 fire rating (Chinese Standard) or an equivalent ASTM E84 Class A rating, meaning they contribute minimally to flame spread and smoke development in case of fire, enhancing safety.

- What is the typical lifespan of PVC Marble Sheet?

Under normal indoor conditions and with proper installation and maintenance, PVC Marble Sheet is highly durable and can last for 10-15 years or even longer. Its UV-resistant coating and robust core material ensure that the aesthetics and structural integrity are maintained over a long period, making fake marble sheet a long-term investment.

The journey from raw materials to a polished artificial marble sheet exemplifies modern manufacturing excellence, combining aesthetic aspirations with practical demands. Sothink Decor's PVC Marble Sheet stands as a testament to this evolution, offering a sophisticated, durable, and cost-effective solution for a myriad of design and construction challenges across residential, commercial, and even selected industrial applications.

For further reading and industry insights, consider these resources:

- Grand View Research Report on Artificial Marble Market: https://www.grandviewresearch.com/industry-analysis/artificial-marble-market

- ASTM International Standards for Plastics: https://www.astm.org/standards/plastics-standards.html

- ISO 9001 Quality Management Systems Overview: https://www.iso.org/iso-9001-quality-management.html

-

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >Aug 05 2025

-

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >Aug 05 2025

-

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >Aug 05 2025

-

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >Aug 05 2025

-

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >Aug 05 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com