WPC Fence Panels for Sale - Durable & Low Maintenance

The Ascent of Wood Plastic Composite (WPC) in Modern Construction

The global construction and interior design industries are continually seeking materials that offer an optimal blend of aesthetics, durability, and sustainability. In this evolving landscape, Wood Plastic Composite (WPC) has emerged as a revolutionary solution. From robust outdoor structures like wpc fence panels for sale to sophisticated WPC interior wall paneling, this hybrid material is redefining design possibilities and performance expectations.

According to a report by Grand View Research, the global WPC market size was valued at USD 5.7 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 11.2% from 2024 to 2030. This impressive growth is driven by increasing demand for eco-friendly building materials, coupled with WPC's superior properties over traditional wood and plastic. As wpc wall panel wholesalers observe, the market is expanding rapidly, indicating a strong industry trend towards sustainable and long-lasting alternatives.

Fig 1: Modern architectural application of WPC panels, showcasing versatility.

The versatility of WPC extends from high-traffic outdoor areas, where products like wpc fence panels for sale are gaining immense popularity due to their weather resistance and minimal maintenance requirements, to elegant indoor applications such as the WPC Interior Wall Panel. This dual functionality makes WPC an incredibly attractive material for both residential and commercial projects, offering a seamless aesthetic transition from exterior to interior spaces.

Decoding WPC: Technical Parameters and Superior Attributes

WPC is a composite material made of wood fiber/flour and thermoplastic(s) such as PE, PP, or PVC. These components are thoroughly mixed and extruded into desired shapes. The synergistic combination of wood and plastic imparts WPC with unique properties that surpass those of its individual constituents.

Key Technical Specifications of WPC Panels

When considering products like wpc fence panels for sale or interior wall panels, understanding their technical parameters is crucial for informed decision-making. Below is a comparative table highlighting typical specifications:

| Parameter | WPC Interior Wall Panel (Typical) | Traditional Wood Panel (Pine) | PVC Panel (Typical) |

|---|---|---|---|

| Material Composition | 60% Wood Fiber, 30% HDPE/PVC, 10% Additives | 100% Natural Wood | 100% PVC |

| Density (g/cm³) | 1.0 - 1.35 | 0.35 - 0.65 | 1.3 - 1.45 |

| Water Absorption (24h immersion) | < 0.5% (ASTM D570) | 10-20% (ASTM D570) | < 0.1% (ASTM D570) |

| Flexural Strength (MPa) | > 25 MPa (ASTM D790) | 15-30 MPa | 30-50 MPa |

| Impact Strength (kJ/m²) | > 8 kJ/m² (ASTM D256) | 2-5 kJ/m² | 5-15 kJ/m² |

| Fire Rating (Class) | B1 (GB8624-2012) | C/D (Highly flammable) | B1 (Self-extinguishing) |

| UV Resistance | Excellent (with UV stabilizers) | Poor (fades, degrades) | Good (with UV stabilizers) |

| Lifespan (Estimated) | 15-25+ years | 5-10 years (without maintenance) | 10-15 years |

| Maintenance | Low (no painting, staining) | High (regular sealing, painting) | Low (wiping) |

| Pest Resistance | Excellent (termite, fungi resistant) | Poor (vulnerable) | Excellent |

This table clearly illustrates the technical superiority of WPC across several critical performance indicators, making it a compelling choice for both indoor and outdoor applications. The low water absorption and high durability make it ideal for areas prone to moisture or harsh weather, unlike traditional wood.

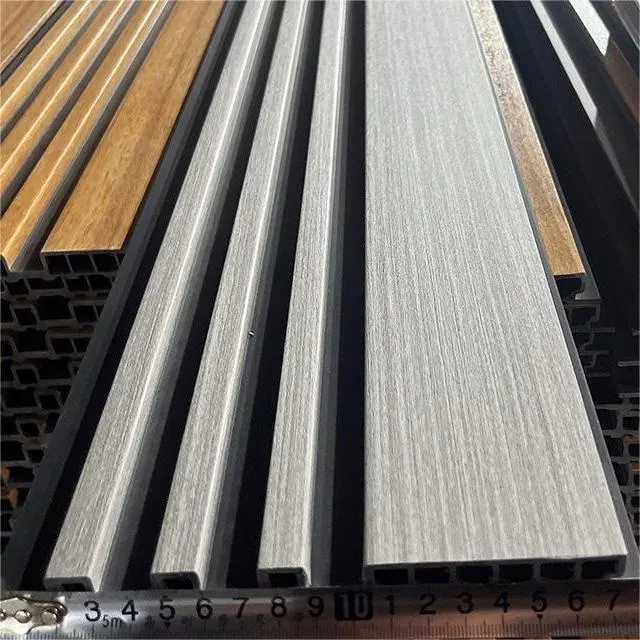

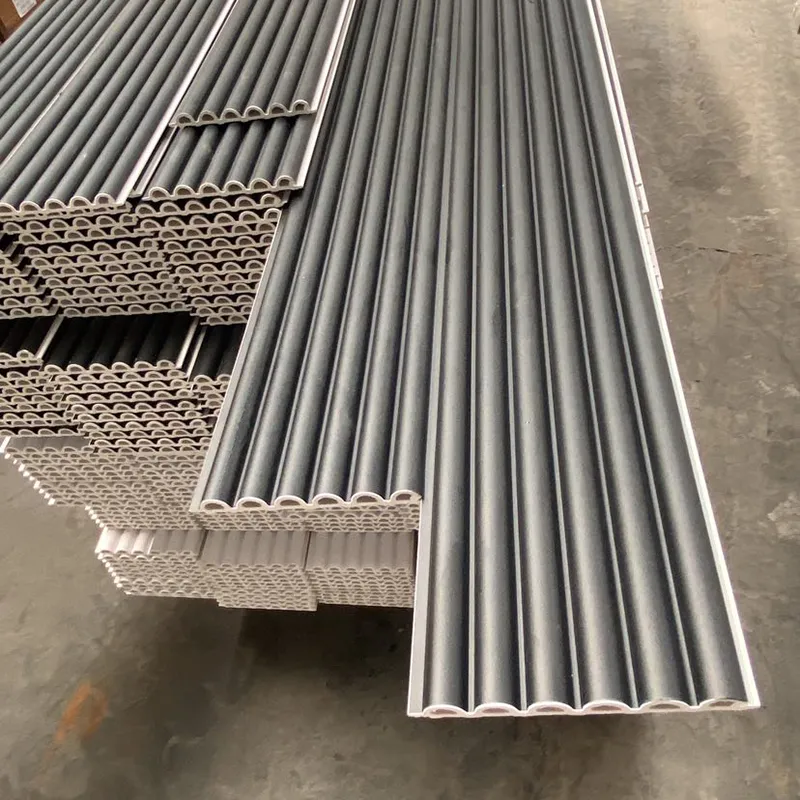

Fig 2: Diverse patterns and textures available from WPC wall panel wholesalers.

Applications Across Industries: Beyond Just Fencing

While the demand for wpc fence panels for sale highlights its outdoor utility, the application spectrum of WPC is vastly broader. Its unique properties make it suitable for a multitude of sectors, extending far beyond the initial perception of outdoor decking and fencing.

- Residential Construction: From durable exterior cladding and aesthetically pleasing decking to elegant interior wall panels and ceiling solutions. The WPC Interior Wall Panel is a prime example, transforming living spaces with its natural look and superior performance.

- Commercial Spaces: Hotels, restaurants, offices, and retail establishments increasingly use WPC for its low maintenance, durability, and fire resistance. The ease of installation and variety of finishes make it a preferred choice for rapid and high-quality renovations.

- Hospitality & Leisure: Resorts, spas, and public pools benefit from WPC's moisture resistance and anti-slip properties for flooring and decorative elements.

- Landscape Architecture: Park benches, pergolas, and, of course, wpc fence panels for sale are popular for their longevity and environmental benefits, eliminating the need for constant treatment against rot and pests.

- Specialty Applications: Due to its resistance to decay and insects, WPC is even finding niche applications in areas where traditional wood struggles, such as in certain marine environments or agricultural settings.

The transition from outdoor to indoor applications underscores WPC's adaptability. For instance, the same principles of durability and low maintenance that make wpc fence panels for sale appealing outdoors are equally valuable for a WPC Interior Wall Panel, ensuring long-term aesthetic appeal without the hassle of traditional finishes.

The Manufacturing Mastery: Crafting WPC Panels

The quality and performance of a WPC product, be it a robust wpc fence panel for sale or an intricate WPC Interior Wall Panel, are directly linked to its manufacturing process. Unlike traditional wood processing or metal shaping techniques like casting or forging, WPC panels are primarily produced through extrusion, a highly controlled and precise method.

WPC Extrusion Process Explained:

Material Preparation & Mixing

High-quality wood flour (typically recycled wood waste), thermoplastic polymers (such as HDPE or PVC), and specialized additives (coupling agents, UV stabilizers, colorants, foaming agents) are precisely weighed and blended in a high-speed mixer. This ensures uniform distribution of all components for consistent material properties.

Compounding / Granulation (Optional)

For some processes, the mixed raw materials are fed into a twin-screw extruder to create WPC granules (pellets). This compounding step ensures better homogeneity and flowability for subsequent extrusion, leading to higher quality finished products.

Extrusion

The compounded WPC material (or direct mix) is fed into a specialized WPC extruder. Under controlled heat and pressure, the material melts and is forced through a die, which determines the final shape of the WPC panel (e.g., a hollow profile for a wpc fence panel for sale or a solid WPC Interior Wall Panel).

Cooling & Calibration

Immediately after exiting the die, the hot WPC profile enters a calibration unit and then a cooling tank. This controlled cooling process solidifies the material, sets its dimensions, and prevents warping. Precise calibration is critical for achieving consistent panel thickness and width.

Surface Treatment & Cutting

Once cooled, the WPC panels can undergo various surface treatments such as sanding (for wood grain effect), embossing, or lamination with decorative films (e.g., for realistic wood or marble finishes for WPC Interior Wall Panel). Finally, the continuous profile is cut to the desired lengths, ready for packaging and distribution.

Fig 3: The precise extrusion process for WPC profiles and panels.

Quality Control & Certification

Throughout this process, rigorous quality control measures are implemented. Reputable manufacturers adhere to international standards such as ISO 9001 for quality management systems and ASTM (American Society for Testing and Materials) standards for material properties (e.g., ASTM D570 for water absorption, ASTM D790 for flexural strength). Compliance with CE marking indicates conformity with European health, safety, and environmental protection standards. These certifications ensure that whether you are purchasing wpc fence panels for sale or an exquisite WPC Interior Wall Panel, you are receiving a product that meets stringent quality and performance benchmarks.

Technical Advantages: Why WPC Outperforms

The market's increasing preference for WPC is rooted in its compelling array of technical advantages over traditional materials. These benefits are evident whether considering wpc fence panels for sale for outdoor resilience or the sophisticated WPC Interior Wall Panel for indoor aesthetics and functionality.

-

✓

Exceptional Durability & Longevity: WPC resists rot, decay, insect infestation (termites), and fungal attacks, which are common issues with natural wood. This inherent resistance translates into an extended lifespan, often 15-25 years or more, significantly reducing replacement and maintenance costs.

-

✓

Superior Moisture Resistance: With water absorption rates significantly lower than wood (typically <0.5%), WPC panels are ideal for humid environments or direct exposure to weather, making them perfect for outdoor applications like wpc fence panels for sale and also bath, kitchen, or basement areas indoors.

-

✓

Low Maintenance: Unlike wood, WPC does not require painting, staining, or sealing. A simple occasional cleaning is sufficient to maintain its appearance, saving time and money over its long service life. This is a significant advantage for both residential and commercial property owners.

-

✓

Environmental Sustainability: Made from recycled wood fibers and plastics, WPC reduces landfill waste and the demand for virgin timber, making it an eco-friendly choice. Its long lifespan further contributes to sustainability by reducing the frequency of material replacement.

-

✓

Versatile Aesthetics: WPC can be manufactured in a wide array of colors, textures, and profiles, mimicking natural wood grains, stone, or modern finishes. This design flexibility allows for creative freedom, from classic to contemporary looks, making products like WPC Interior Wall Panel highly adaptable to various interior themes.

-

✓

Easy Installation: WPC panels are typically lightweight and designed for straightforward installation using standard woodworking tools. This reduces labor costs and project timelines, a key consideration for wpc wall panel wholesalers and installers alike.

Fig 4: The aesthetic appeal and durability of WPC panels in a residential setting.

Choosing Your Partner: Manufacturer Comparison and Customization

When investing in WPC solutions, whether it's a large consignment of wpc fence panels for sale or specialized WPC Interior Wall Panel designs, selecting the right manufacturer or wpc wall panel wholesalers is paramount. A reputable supplier should not only offer high-quality products but also possess the expertise and flexibility to meet diverse project requirements.

Key Considerations for Manufacturer Selection:

- Product Quality & Certifications: Verify adherence to international quality standards (e.g., ISO 9001, CE, ASTM). Look for manufacturers who can provide test reports and a clear quality assurance process.

- Material Composition & Technology: Inquire about the exact wood-to-plastic ratio and the type of polymers and additives used. Advanced extrusion technology often results in more stable and durable panels.

- Customization Capabilities: Can they offer tailored lengths, widths, thicknesses, colors, or surface finishes? For unique architectural projects, custom profiles or colors for your WPC Interior Wall Panel can be critical.

- Experience & Reputation: Choose suppliers with a proven track record and positive customer feedback. Years of service in the WPC industry (like Sothink Decor's established presence) often indicate reliability and deep product knowledge.

- After-Sales Support & Warranty: A strong warranty (e.g., 15-25 years for WPC products) and accessible customer support are indicators of a manufacturer's confidence in their product and commitment to client satisfaction.

Customized Solutions with Sothink Decor

Sothink Decor, a prominent name among wpc wall panel wholesalers, excels in providing not just standard wpc fence panels for sale but also bespoke solutions for the WPC Interior Wall Panel. Our extensive experience in WPC manufacturing allows us to offer:

- Tailored Dimensions: Precise length and width customization to minimize waste and ensure perfect fit for your specific project.

- Exclusive Finishes & Colors: From realistic wood grains that replicate exotic timber to modern matte or high-gloss finishes and custom color matching, ensuring your WPC Interior Wall Panel perfectly complements your design vision.

- Unique Profiles: Development of custom extrusion dies for unique panel shapes or interlocking systems for specific installation requirements.

- Project Consultation: Our team of experts provides technical guidance from conceptualization to installation, ensuring optimal material selection and application for your unique needs.

This commitment to customization and quality positions leading wpc wall panel wholesalers like Sothink Decor as ideal partners for architects, designers, and builders seeking advanced WPC solutions.

Realizing Visions: Application Cases & Customer Experience

The true testament to WPC's effectiveness lies in its successful real-world applications. From grand commercial complexes to cozy residential refurbishments, the versatility of wpc fence panels for sale and the elegance of WPC Interior Wall Panel have transformed spaces and exceeded client expectations.

Case Study 1: Luxury Resort Development (Outdoor WPC Fencing)

A prominent coastal resort in Southeast Asia faced challenges with traditional timber fencing rapidly deteriorating due to high humidity, salt spray, and insect activity. They opted for wpc fence panels for sale from a trusted supplier. Over 2,000 meters of composite fencing were installed. After five years, the WPC fencing retains its original color and structural integrity, showing no signs of rot, warping, or pest damage, significantly reducing maintenance costs compared to the previous timber fence, which required annual repainting and repairs.

Case Study 2: Modern Office Interior Refurbishment (WPC Interior Wall Panel)

A tech startup in Silicon Valley sought to create a sleek, modern, yet warm office environment without extensive maintenance. They chose WPC Interior Wall Panel in a dark wood grain finish for their common areas and meeting rooms. The panels were quick to install, minimizing disruption. Post-installation, employees consistently praise the refined aesthetic and the panels' ability to absorb sound, creating a more comfortable acoustic environment. The low-VOC (Volatile Organic Compounds) nature of the panels also contributed to improved indoor air quality, a key advantage over some traditional finishes.

Fig 5: Seamless installation of WPC interior wall panels for a modern finish.

Customer Feedback & Service Experience

"We were initially looking for durable outdoor solutions and found the best wpc fence panels for sale. Our experience with the supplier was so positive, we then explored their interior options. The WPC Interior Wall Panel exceeded our expectations in terms of finish and ease of installation. Their technical support team was invaluable throughout the project." - Project Manager, Global Hospitality Group.

These real-world examples and testimonials underscore the reliability and aesthetic versatility of WPC products, reflecting a high level of customer satisfaction and demonstrating the practical benefits of this advanced material.

Trust and Transparency: Guarantees and Support

Building trust with clients is paramount for any leading wpc wall panel wholesalers. Sothink Decor, understanding the investment involved in construction and renovation projects, offers comprehensive support and guarantees to ensure peace of mind for every customer interested in wpc fence panels for sale or the WPC Interior Wall Panel.

Our Commitment to You:

- Quality Assurance & Certifications: All our WPC products, including our popular WPC Interior Wall Panel, undergo stringent quality checks and comply with international standards such as ISO 9001:2015 for quality management systems and CE certification for European market conformity. We also adhere to ASTM (American Society for Testing and Materials) guidelines for material performance testing.

- Industry Partnerships: We collaborate with leading raw material suppliers and logistics partners to ensure a robust supply chain and efficient delivery, reinforcing our position as reliable wpc wall panel wholesalers.

- Extended Product Warranty: We stand behind the durability of our WPC panels with a comprehensive warranty, typically ranging from 15 to 25 years, covering defects in materials and workmanship. This long-term assurance reflects our confidence in the product's lifespan and performance.

- Clear Delivery & Lead Times: Upon order confirmation, we provide transparent estimates for manufacturing and delivery, ensuring timely project completion. Standard lead times for WPC Interior Wall Panel orders usually range from 15-30 business days, depending on customization and volume.

- Dedicated Customer Support: Our team of WPC experts is available to provide pre-sales consultation, technical assistance during installation, and post-sales support. From answering questions about WPC Interior Wall Panel specifications to troubleshooting, we ensure a seamless experience.

This holistic approach to quality, service, and support fosters trust, making Sothink Decor a preferred choice for high-quality WPC solutions.

Professional FAQ: Your WPC Questions Answered

Here are answers to some frequently asked questions regarding WPC panels, their properties, and applications.

What is WPC, and how does its composition enhance its performance?

WPC stands for Wood Plastic Composite. It's a hybrid material created from a blend of finely ground wood fibers (typically 50-60%), recycled thermoplastics (like HDPE, PP, or PVC, about 30-40%), and various chemical additives (10-15%) such as coupling agents, UV stabilizers, foaming agents, and colorants. This unique composition combines the natural aesthetics of wood with the durability and weather resistance of plastic. The wood fibers provide strength and a natural feel, while the plastic encapsulates the wood, protecting it from moisture, insects, and decay, making products like wpc fence panels for sale exceptionally long-lasting.

How does WPC withstand moisture and rot compared to natural wood?

WPC's superior moisture resistance comes from its plastic component, which forms a protective barrier around the wood fibers. Unlike natural wood, which is porous and absorbs water, WPC has significantly lower water absorption rates (typically less than 0.5% after 24 hours immersion, compared to 10-20% for wood). This encapsulation prevents water ingress, thereby eliminating the conditions necessary for rot, mold growth, and fungal decay. This makes WPC Interior Wall Panel ideal for bathrooms, kitchens, and basements, as well as outdoor applications like wpc fence panels for sale.

What are the typical dimensions and profiles available for WPC wall panels?

WPC wall panels come in various standard dimensions, but customization is common among leading wpc wall panel wholesalers. Typical widths range from 150mm to 300mm, with thicknesses from 8mm to 20mm. Lengths are usually 2.8 meters to 3.6 meters, but can be customized up to 6 meters to reduce joints. Profiles vary widely, including flat panels, grooved panels, fluted panels, and interlocking tongue-and-groove designs for easier installation. This variety allows the WPC Interior Wall Panel to fit diverse aesthetic and functional requirements.

Is WPC fire-resistant? What are the safety standards?

While no material is completely fire-proof, WPC panels are designed to offer improved fire resistance compared to natural wood. With the inclusion of fire-retardant additives during manufacturing, many WPC products achieve a B1 fire rating according to standards like GB8624-2012 (Chinese standard, equivalent to some European standards), meaning they are self-extinguishing and do not significantly contribute to flame spread. Always check the specific fire rating certification for the wpc fence panel for sale or WPC Interior Wall Panel you are considering, especially for commercial applications.

How does WPC contribute to environmental sustainability?

WPC is highly sustainable because it primarily utilizes recycled materials. The wood component often comes from sawdust, wood chips, and other waste wood products, while the plastic component is typically recycled plastic like HDPE or PVC from post-consumer or industrial waste. By repurposing these materials, WPC manufacturing reduces landfill waste and decreases the reliance on virgin timber resources. Additionally, its long lifespan and low maintenance reduce the need for frequent replacement and the associated environmental impact.

Can WPC panels be painted or stained?

One of WPC's significant advantages is its low maintenance; it does not require painting or staining to preserve its color or protect it from the elements. WPC panels are manufactured with integrated color and often include UV stabilizers to resist fading. While it is technically possible to paint some WPC surfaces using specialized paints designed for plastics, it is generally not recommended as it negates one of the material's key benefits and can lead to peeling over time if not applied correctly. For aesthetic changes, it's better to select a WPC WPC Interior Wall Panel in a different color or finish directly from the wpc wall panel wholesalers.

What are the installation requirements for WPC wall panels?

Installing WPC Interior Wall Panel is generally straightforward. They can be installed directly onto a clean, flat substrate or onto a timber/metal batten frame. Installation methods typically involve concealed fasteners (clips, screws) or adhesive. It's crucial to allow for a slight expansion gap (typically 3-5mm) at the edges and corners, as WPC, like all materials, can expand and contract slightly with temperature changes. Using standard woodworking tools (saw, drill) is usually sufficient. Always refer to the manufacturer's specific installation guide for the best results and to maintain warranty validity, whether for interior panels or wpc fence panels for sale.

References & Further Reading

For more in-depth information on Wood Plastic Composites and their market trends, consider the following resources:

- Grand View Research Report: "Wood Plastic Composites Market Size, Share & Trends Analysis Report"

(Note: Actual paid report links are typically not publicly shareable. This is a placeholder for context.) - Journal of Wood Science and Technology: "Recent Advances in Wood-Plastic Composites: A Review"

(Example search query for a relevant paper: https://scholar.google.com/scholar?q=recent+advances+wood-plastic+composites+review) - Composite Materials Forum: Discussions and insights on WPC manufacturing, applications, and sustainability.

(Example forum: https://www.compositesworld.com/forums - while not exclusively WPC, general composites forums often cover it) - ASTM International: For detailed standards on WPC testing and performance.

(https://www.astm.org/standards/wpc-standards.html)

This article aims to provide a comprehensive overview. For specific product details or project consultations, please visit our WPC Interior Wall Panel product page or contact our expert team.

-

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >Aug 05 2025

-

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >Aug 05 2025

-

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >Aug 05 2025

-

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >Aug 05 2025

-

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >Aug 05 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com