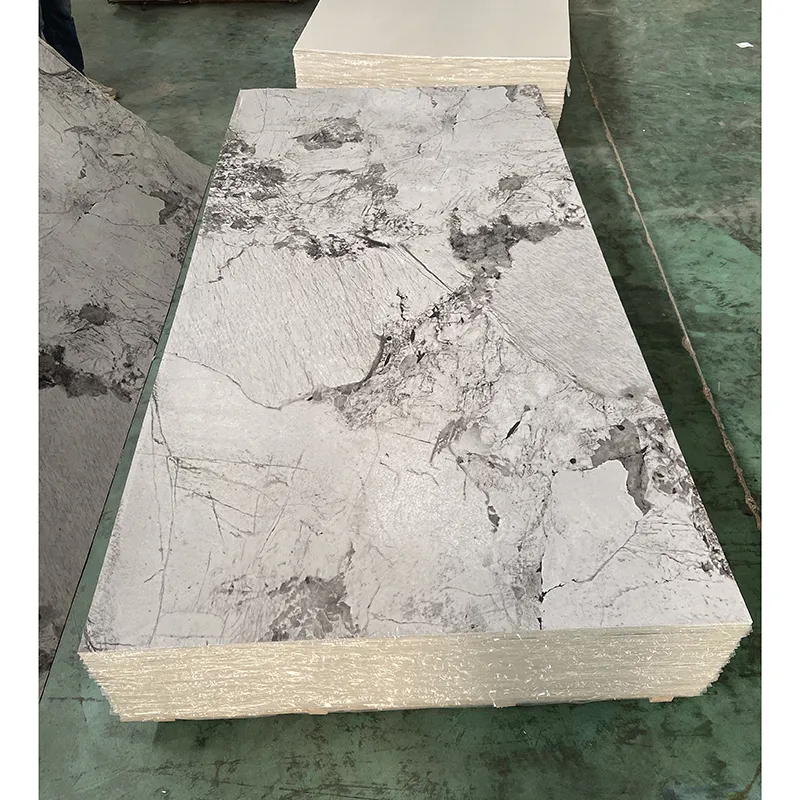

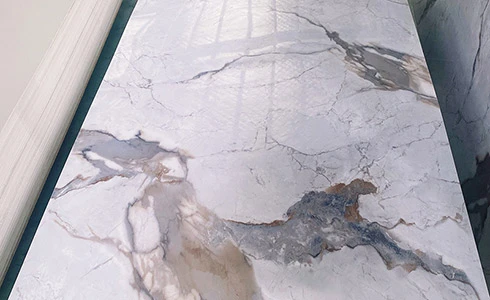

Premium Artificial Marble Sheet for Stylish Interiors

Artificial marble sheet products are revolutionizing the architectural and interior design landscape, offering cost-efficient aesthetics and unmatched versatility. As end-users and industry stakeholders increasingly seek innovative, sustainable, and easy-to-maintain materials, products like PVC Marble Sheet (artificial marble sheet) are becoming critical in commercial and residential projects.

Global Industry Trends: Artificial Marble Sheet

According to MarketsandMarkets, the artificial marble market surpassed USD 52 billion in 2023 and is projected to reach USD 76 billion by 2028, registering a CAGR of 6.5%. Innovations such as bedroom PVC marble sheet designs and flex marble sheet technologies have contributed to the expansion of applications in hotel, retail, and luxury residential segments.

Key Industry Drivers:

- Green Building Trends: Driven by the sustainability and recyclability of PVC and other polymer-based artificial marble sheet options.

- Customization & Flexibility: Surge in demand for bedroom PVC marble sheet designs and flex PVC marble for unique aesthetics.

- Installation Efficiency: Lightweight panels and easy fake marble sheet installation reduce overall project timelines by up to 60%.

Artificial Marble Sheet: Product Parameter Comparison

| Parameter | PVC Marble Sheet | FRP Marble Sheet | Ceramic Marble Tiles | Natural Marble |

|---|---|---|---|---|

| Thickness (mm) | 2.5–10 | 2–6 | 8–15 | 18–25 |

| Weight (kg/m²) | 2.1–10 | 2.8–8 | 18–28 | 30–60 |

| Flexibility | Good (bend radius 300mm) | Moderate | Rigid | Rigid |

| UV Resistance | High (ISO 4892-3:2013) | Medium | High | High |

| Fire Retardancy | B1 (EN 13501-1) | B2 | A1 | A1 |

| Customization | Excellent | Good | Limited | Limited |

| Cost (USD/m²) | 9–15 | 14–21 | 24–65 | 68–150 |

Source: Industry data analysis, manufacturer technical sheets, and Plasticsheetsshop.

Manufacturing Process: Artificial Marble Sheet Explained

Modern artificial marble sheet manufacturing leverages advanced casting, calendaring, and lamination technologies. Here’s a workflow visual:

Technical Highlights: All artificial marble sheet panels are manufactured to strict ISO 7823-1:2003 dimensional tolerances, with advanced flame-retardant additives (certified EN 13501-1/B1). Each batch undergoes ISO 178 flexural strength testing and ISO 4892-3 UV aging tests to guarantee performance and service life.

Technical Specifications & International Standards

| Product Name | PVC Marble Sheet | ||

|---|---|---|---|

| Core Material | PVC Resin (SG-5) + CaCO₃ | Modified for fire resistance | Free of heavy metals |

| Surface Finish | High-gloss, Matte, Embossed, Texture Print | Customizable, digital marble patterns | |

| Thickness (mm) | 2.5 / 3 / 4 / 5 / 6 / 8 / 10 | Other thicknesses on request | |

| Size (mm) | 1220x2440 | Custom cut-to-size | Max 1600x3200 |

| Density (g/cm³) | 1.28–1.45 | ISO 1183 tested | |

| Flexural Strength | >16 MPa | ISO 178 Standard | - |

| Fire Rating | B1 | EN 13501-1 | - |

| UV Resistance | ΔE | Excellent anti-fading | - |

| Service Life | > 18 years* | *Lab simulated aging | |

- Detection Standards: ISO 178, ISO 1183, ISO 4892-3, EN 13501-1

- Application Scope: Hotel/furniture/wall cladding/bathroom/kitchen/lift cabins

- Water Absorption:

- Chemical Resistance: Excellent, suitable for hospital/pharma labs

Product Performance Comparison: PVC Marble Sheet vs. Ceramics & Natural Marble

Market Application Distribution: Artificial Marble Sheet

Key Application Scenarios & Case Studies

Used for TV backdrop walls and wardrobe sliding doors in premium apartments. Custom gold-vein patterns boost property perceived value by +18% (Source: developer case study, Shanghai 2023).

3200m² of flex marble sheet supplied to a 5-star hotel in Dubai. Quick, dry installation cut timeline by 30%. Result: reduced labor costs, minimal construction dust.

Elevators and corridors upgrade with flex PVC marble panels improved graffiti resistance, enabling simple daily cleaning and 5-year surface warranty.

Artificial marble sheet passes SGS anti-microbial and ASTM E84 flame test; installed in pharma production cleanrooms.

Leading Artificial Marble Sheet Manufacturers: Comparative Analysis

| Manufacturer | ISO Certification | Key Product | MOQ | Annual Capacity | Notable Clients |

|---|---|---|---|---|---|

| Sothink Decor | ISO9001:2015, ISO14001:2015 | PVC Marble Sheet | 200 sheets | 2,500,000m² | Country Garden, CR Land |

| ABC Polymarble (India) | ISO9001:2015 | Polymarble Flex Sheet | 500 sheets | 1,200,000m² | Lodha, TATA |

| Royal King PVC (Malaysia) | ISO9001, RoHS | PVC Faux Marble | 300 sheets | 880,000m² | Sime Darby |

Sothink Decor leads in flexible supply, industry customization (hotel/residential/commercial), and holds certifications (ISO, SGS, CE, RoHS), enhancing project compliance worldwide.

Customization Services & Solution Packages

- Design: Any size, color, digital pattern (inc. 3D marble veins, metallic accent, matte/granite finishes).

- Cut-to-size: CNC precision cutting for bedroom pvc marble sheet designs, kitchen backsplashes, columns, etc.

- Fire Class upgradation: B1-B2 tailored for commercial buildings, schools, hospital standards.

- Accessory Supply: Provide end trims, matching profiles, adhesives, fasteners.

- Technical Consulting: On-site measurement, installation method training, and maintenance guidelines.

Warranty, Quality Control & Customer Support

- Warranty Term: 5–8 years product replacement warranty for all artificial marble sheet panels.

- Quality Inspection: 27 checkpoints per ISO9001:2015/SGS; full documentation provided.

- After-Sales Support: 24/7 online engineer assistance, video/install guidance, rapid claims.

- Global Services: Projects supplied in 42+ countries; references available on request.

- Environmental Compliance: RoHS/CE/FDA-compliant for safe use in hospitals and food zones.

Frequently Asked Technical Questions (FAQ)

Customer Experience: Feedback & Testimonials

“Our hotel wall project with Sothink Decor’s artificial marble sheet delivered stunning visual impact, fast install, and easy daily cleaning. Highly recommended for premium interiors!”

— Facilities Manager, 5 Star Resort, UAE

“Switching to flex pvc marble enabled our designers to realize bold bedroom PVC marble sheet designs that natural stone simply can’t achieve.”

— Lead Designer, Shanghai Residential Project

Conclusion: The Next Generation Artificial Marble Sheet Solution

- EEAT Superiority: Professional-grade product, tight specification control, global certification, and extensive market track record.

- Both aesthetics and engineering performance outshine ceramics/natural stones, especially in curve/flex and rapid install projects.

- Proven cost savings (up to 40%), with secure warranties and robust customer support.

- Applications span hotels, high-end real estate, commercial, healthcare, elevator cabs, and modular interiors globally.

- Industry-standard references for further research: iHouse Architecture Forum, Journal of Cleaner Production.

-

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >Mar 17 2025

-

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >Mar 13 2025

-

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >Mar 13 2025

-

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >Mar 13 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com