1. Market Trends & Industry Insights: The Rise of SPC flooring wholesale

Stone Plastic Composite (SPC) Flooring is transforming the commercial and residential flooring landscape. The global SPC flooring market surpassed USD 4.5 billion in 2023 and is projected to reach USD 7.2 billion by 2027 (Source: Statista), growing at a CAGR of 10.1%. This growth is fueled by surging construction activities, stringent environmental standards, and demand for durable, waterproof, and easy-to-install solutions.

- Asia-Pacific leads as the largest producer and exporter of SPC flooring wholesale products, followed by North America and Europe.

- E-commerce and B2B portals have shortened delivery cycles, fostering faster global supply matching for spc flooring for sale.

- End users increasingly prefer composite core click flooring & sustainable materials, with commercial, hospitality, and educational sectors driving application expansion.

SPC Flooring Wholesale Technical Trends (2019-2024)

2. Full Technical Overview: Structure & Specs of SPC Flooring Wholesale

- UV coating: Surface scratch, stain, and fade resistance layer.

- Wear layer (0.3mm–0.7mm): Provides abrasion, impact, and slip resistance; measured in T (Thickness) grades.

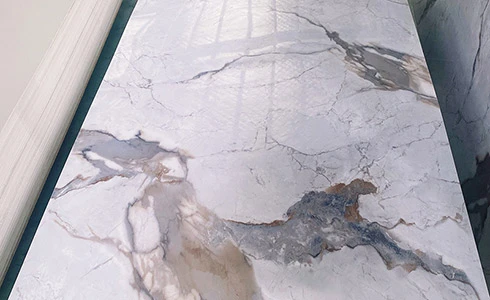

- Printing film: High-resolution decorative film for wood/stone/ceramic effect.

- SPC core layer: Stone (limestone/CaCO3) + polymer resin, using extrusion technology for 100% waterproof and rigid stability.

- Underlayment: IXPE/EVA/cork optional, enhances footfall comfort, acoustics, anti-moisture.

- Click system: Patented Unilin/I4F locking for seamless DIY installation.

2.1 Standard Technical Data Table

| Parameter | SPC Flooring Wholesale Standard | Composite Core Click Flooring | Composite Stone Flooring |

|---|---|---|---|

| Total Thickness (mm) | 3.5–8.5 | 4.0–10.0 | 5.0–12.0 |

| Wear Layer Thickness (mm) | 0.2–0.7 | 0.3–1.0 | 0.3–1.2 |

| Stability (EN 434) | ≤0.05% | ≤0.06% | ≤0.07% |

| Fire Rating | Bf1-S1 (EN 13501-1) | Bf1-S1 | Bf1-S1 |

| Surface Abrasion | ≥10000 cycles (EN 660-2) | ≥12000 cycles | ≥15000 cycles |

| Formaldehyde | E0/No detection | E0/E1 | E0/E1 |

| Slip Resistance | R10–R12 | R10–R12 | R12–R13 |

2.2 SPC Flooring Manufacturing Process (Infographic)

Production Flow of SPC Flooring Wholesale

- Raw Material Mixing: Limestone powder (70%), polyvinyl chloride (PVC) resin (25%), stabilizers, colorants.

- Extrusion: Twin-screw extruder shapes SPC sheets (precision CNC calibration for thickness & density control).

- Lamination: Heat and pressure bond PVC decor film, wear layer, and UV-coating.

- Embossing: Deep or registered embossing for realistic textures (using steel/diamond pattern rollers).

- Click System Cutting: German “HOMAG CNC” routers create precise Unilin/I4F lock grooves.

- Quality Inspection: Automated vision, pull, and abrasion tests (ISO/ANSI conformity).

- Packing & logistics: Automatic shrink-pack & container111 loading, barcode QC traceability.

Material Advantages

- SPC core: Rigid, dent/scratch/waterproof, 30+ years lifespan

- Complies with ISO 10582 (Resilient, Rigid Floor Coverings) & EN 14041 standards

- 100% recyclable and phthalate-free / formaldehyde-free

Manufacturing Technology

- Extrusion: German-imported twin-screw extruders guarantee core density uniformity

- CNC Clicking: Unilin/I4F patent click ensures composite core click flooring seamlessness

- Embossing: Deep-registered emboss matches real wood/stone texture

Industry Certifications

- ISO 9001, ISO 14001, Floorscore®, CE, SGS

- Fire rating: Bf1-S1 (EN 13501-1)

- Slip resistance: R10–R12 (DIN 51130)

SPC Flooring vs. Other Resilient Flooring — Technical Comparison

3. Factory Comparison: Leading SPC Flooring Wholesale Suppliers

| Supplier | Production Capacity | Main Markets | Certificates | Lead Time | Custom Service |

|---|---|---|---|---|---|

| Sothink Decor | 5M m²/year | EU, USA, Middle East | ISO 9001, EN 14041, CE, FloorScore | 18–25 days | OEM/ODM |

| Novalis® | 8M m²/year | North America, EU | ISO, GREENGUARD | 22–32 days | OEM |

| Wellmade® | 4M m²/year | USA, Canada | CE, SGS | 24–30 days | OEM, logo packaging |

| Kronospan® | 6M m²/year | EU, CIS | EN, ISO, PEFC | 28–40 days | OEM |

4. Customization & Solution Offering

OEM/ODM Options

- Thickness: 3.5–10mm options, with wear layer 0.2–1.2mm for varying levels of traffic resistance.

- Plank size: 1220x180mm, 1520x230mm, 610x305mm, custom dimensions upon request.

- Surface Decoration: Over 500+ wood/stone/ceramic films, RFP (registered embossed), matt/gloss finishes available.

- Underlayment: IXPE/EVA/cork; optional antibacterial, anti-static, or recycled materials for LEED projects.

- Packaging: Brand printing, shrink/box/custom logistics barcode.

SPC Flooring Product Distribution by Application (2023)

5. Application Scenarios & Case Studies

Main Usage Sectors:

- Residential housing – apartments, villas, modular homes

- Commercial offices, retail outlets, cafes

- Hospitality – hotels, serviced apartments, boutique hostels

- Healthcare & clinics (antibacterial options)

- Educational facilities – schools, libraries, labs

- Industrial/Institutional – laboratories, utility buildings

Case Study #1: 5-Star Hotel Chain, Dubai, UAE – Composite Core Click Flooring

- Scope: 65,000 m² SPC flooring (thickness 5.0mm, IXPE pad)

- Challenge: Required 100% waterproof flooring, anti-slip (R11), fast installation, and premium wood grain aesthetics.

- Outcome: Installation rate: 750 m²/day with 24/7 rapid click-lock system, no adhesives necessary, outperforming WPC/LVT carpet.

- Feedback: After 2 years: 0 warping, scratch complaints & easy cleaning in high-traffic hotel corridors and suites.

Case Study #2: US Public School Modernization Program – Composite Stone Flooring

- Scope: 41,450 m² upgraded to 6mm composite stone SPC flooring

- Result: Significant reduction in lifetime maintenance costs. No formaldehyde emission (tested per ISO16000-9), improved classroom acoustics by 22%.

- Installer Note: “Click system enabled speed, and the anti-slip surface provided a safe, easy-clean solution for high-traffic corridors.”

Case Study #3: Petrochemical Industry Facility, Asia – Industrial Application

- Challenge: Corrosive environment, heavy machinery, spill risk

- Material: 7mm thick composite core click flooring, R12 anti-slip, heavy-duty emboss, antibacterial.

- Outcome: 3 years in-service: 0 failure, compared favorably with ceramic and traditional vinyl tiles per ISO 10874 Cogeneration testing.

6. Professional FAQ for SPC Flooring Wholesale

A1: SPC = Stone Plastic Composite, a rigid flooring made from natural limestone powder, PVC, and stabilizers. It offers higher dimensional stability, is 100% waterproof and denser than WPC (Wood Plastic Composite) or LVT (Luxury Vinyl Tile).

A2: Key specs: total thickness (mm), wear layer thickness (mm), core density, click system type (Unilin/I4F), fire (EN 13501) and slip resistance (R rating), formaldehyde level (E0/E1), and certifications (FloorScore/SGS).

A3: Follow ISO 10582/ANSI/ASTM F3261 for resilient floor covering, use floating installation (DIY click) on dry, flat subfloors, with expansion gaps as required.

A4: Yes. Thanks to the dense core and rigid structure, SPC passing EN 660-2 ≥10000 abrasion cycles and EN 425 castor chair tests is ideal for high-traffic and rolling load environments.

A5: Factory-tested lifespan: 20–30 years. Sothink Decor’s wholesale SPC flooring comes with 15–20 year residential and 10–15 year commercial wear warranty.

A6: Absolutely. Custom SPC available with nano-silver or copper-ion surface, anti-static coatings, recycled content for LEED compliance upon request.

A7: Lead time: 18–25 days for standard orders. Dedicated QC, technical consulting, and global after-sales support from Sothink Decor (or your selected supplier).

7. Quality Assurance & Authority Credentials

- Over 12 years’ OEM/ODM experience in spc flooring wholesale.

- Cooperation with top architectural firms & leading retailers globally.

- Referenced by Floor Covering News, BSI ISO, and Statista Market Data.

8. Delivery, Warranty & After-Sales Service

| Service | Sothink Decor | Industry Average |

|---|---|---|

| Lead Time (Container) | 18–25 days | 25–40 days |

| Factory Warranty | 20 years (resid.) / 10 years (comm.) | 10–15 years / 5–10 years |

| Post-Shipment Support | Online 24/7, on-site (project) | Email/partial phone |

| Product Traceability | Batch barcode, online code | Partial |

| OEM/ODM Custom Service | YES | Partial/On request |

9. Conclusion & Resources

1. Statista, “Global SPC Flooring Market Forecast 2023–2027”: View data

2. Floor Covering News, “SPC: Next-Gen Resilient Flooring Solutions”: Read article

3. BSI ISO, “ISO 10582: Resilient Floor Coverings”: Standard link

4. Floor Covering Weekly, “Design & Innovation: SPC & Composite Core Trends”: See trends

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com