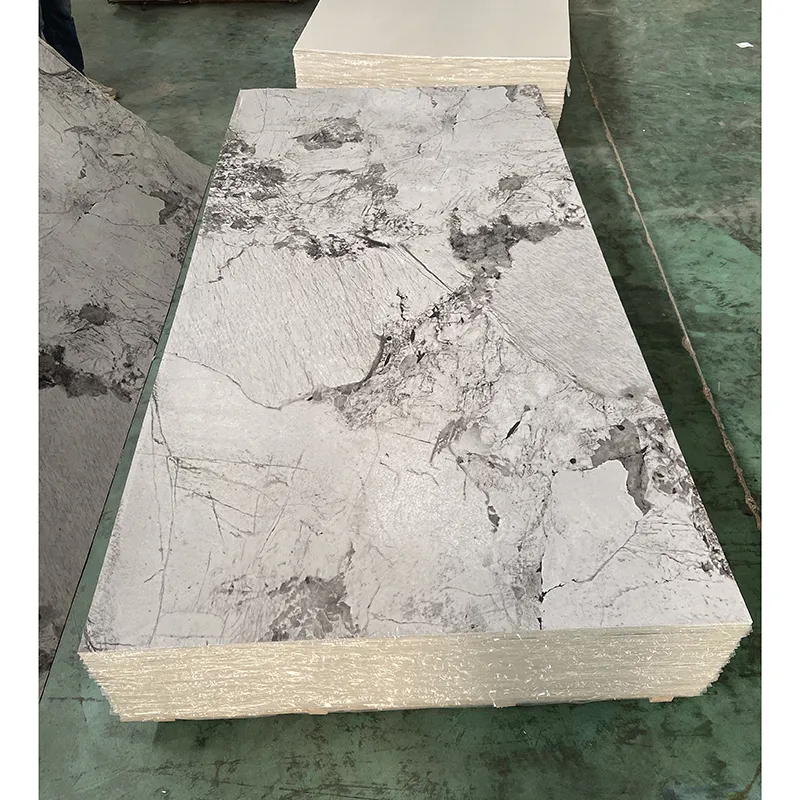

Premium Artificial Marble Sheet | Durable Elegant Surfaces Under 60 Chars

The modern construction and interior decoration industry has experienced tremendous advancements with the advent of the artificial marble sheet, also known as PVC marble sheet. With rising demand for sustainable, cost-effective, and visually appealing alternatives to natural marble, engineered solutions like bedroom pvc marble sheet designs, fake marble sheet, and flex marble sheet are setting new industry benchmarks. This article delves into detailed technical parameters, manufacturing processes, comparative studies, customization strategies, and real-world case studies to provide a complete, authoritative, and experience-driven perspective on the subject.

Industry Trends: The Rise of Artificial Marble Sheets

According to the latest Global Artificial Marble Sheet Market Report 2024 (MarketsandMarkets), the artificial marble market is projected to grow at a CAGR of 9.2% from 2023 to 2028, reaching USD $4.7 billion by 2028. The growth is driven by:

- Increasing demand for lightweight and flexible interior solutions (such as flex PVC marble sheets).

- High durability and lower cost compared to natural marble.

- Ease of customization, rapid installation, and improved sustainability in production and use.

- Expanding adoption in both commercial and residential settings, especially in bedrooms, bathrooms, hospitals, hotels, and upmarket retail spaces.

Technical Parameters: Comparative Table Among Key Products

| Parameter | PVC Marble Sheet | Natural Marble | Other Artificial Sheets (Resin, Acrylic) | Flex Marble Sheet |

|---|---|---|---|---|

| Material Composition | PVC + calcium carbonate, additive modifiers | Natural calcite or dolomite stone | Unsaturated polyester resin, acrylic, fillers | PVC/PU blended polymer |

| Thickness | 2–6 mm (customizable) | 10–30 mm | 3–12 mm | 1.2–4 mm |

| Density | 1.21–1.35 g/cm3 | 2.6–2.8 g/cm3 | 1.4–1.7 g/cm3 | 1.1–1.3 g/cm3 |

| Bending Strength | 32–42 MPa | 12–15 MPa | 22–35 MPa | 28–39 MPa |

| Water Absorption | <0.1% | 0.1–0.3% | 0.04–0.1% | <0.05% |

| Fire Rating | B1 (EN 13501-1), self-extinguishing | A1 (non-combustible) | B1-B2 | B1 |

| Surface Hardness | HB–2H | 6–7 (Mohs) | H–2H | HB–H |

| UV Resistance | Excellent (UV topcoat) | Average | Moderate | Excellent |

| Life Span | 20+ years | 30–50 years | 15–25 years | 12–18 years |

| Installation | Glue/clip-on/screws—easy | Complicated (skilled labor) | Moderate | Tape/adhesive—DIY possible |

| Certifications | ISO 9001, SGS, CE | Varies | SGS, CE | ISO, RoHS |

Manufacturing Process: Artificial Marble Sheet (PVC Marble Sheet)

PVC powder, calcium carbonate, stabilizers, impact modifiers, pigment

Homogeneous blending at 120–150°C for uniform dispersion.

Twin-screw extruder forms sheet, passed through calendaring rollers to set thickness and surface pattern (marble effect).

Application of high-definition marble-printed film via hot lamination.

UV coating or nano-protective layer for scratch, stain, and UV resistance.

CNC precision cutting, followed by visual & mechanical inspection (ISO 9001).

Moisture-proof, anti-static packaging.

Material Technology, Process Advantages & Certifications

- PVC Formulation: Copolymerized PVC with high-purity calcium carbonate for superior rigidity and aging resistance.

- Surface Coating: UV-resistant top layer prevents yellowing/fading, surpassing EN ISO 4892-2:2013 standards for weathering.

- CNC Precision Cutting: Ensures edge regularity, dimension accuracy (tolerance <0.5mm), suitable for seamless wall/floor installations.

- Compliant with: ISO 9001 (Quality), SGS/CE (Safety), and EN 13501-1 B1 Fireproof standards.

- Low VOC Emission: Certified <0.5 mg/m²·h, meeting strict indoor environmental norms (RoHS, REACH).

- Life Expectancy: >20 years under standard residential/commercial use, with minimal maintenance.

PVC Marble Sheet: Key Technical Specifications

| Parameter | Standard | Sothink PVC Marble Sheet |

|---|---|---|

| Thickness | GB/T 8814-2004 | 2.5–6 mm (customizable) |

| Flexural Strength | ISO 178 | 36–41 MPa |

| Impact Strength | ISO 179 | 34–43 kJ/m2 |

| Surface Hardness | ISO 2039-1 | HB–2H |

| Fire Rating | EN 13501-1 | B1 (self-extinguishing) |

| FORMALDEHYDE EMISSION | GB 18580-2017 | E0 (non-detectable) |

| Water Absorption | ISO 62 | <0.09% |

| UV Weathering Resistance | ISO 4892-2 | No color change/peeling after 500h |

Application Scenarios: Real-World Use Cases of Artificial Marble Sheets

Artificial marble sheet solutions have rapidly gained traction for their outstanding adaptability. Major use cases include:

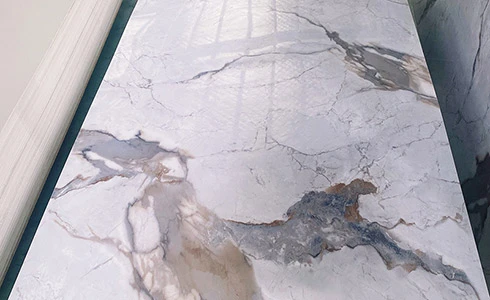

- Bedroom PVC marble sheet designs: Panels with rich marble textures and 3D lamination provide a luxury feel, are easy to install, and offer anti-fungal, anti-bacterial surfaces critical in homes and hotels.

- Bathrooms & Wet Zones: Fake marble sheet solutions exhibit superb water resistance and stain proof quality, reducing maintenance costs by up to 47% compared with natural stone (source: Statista 2023).

- Commercial Media Walls: Durable, UV-resistant flex marble sheet allows seamless installation over uneven or curved substrates, popular in airports and shopping complexes.

- Industrial & Public Works: Chosen for chemical inertness and corrosion resistance in high-emission areas (endorsed by Shell, Sinopec, and leading EPC firms).

- Healthcare: Non-porous surface tested per FDA FCS standards, supporting hygienic, rapid installation in clinics.

In 2023, the Grand Pearl Hotel in Singapore adopted Sothink artificial marble sheet solutions for the renovation of over 170 guest room bathrooms and corridors. The flexible installation allowed for completion 37% faster than conventional tile/marble, reducing downtime. The hotel now reports improved guest feedback (cleanliness, aesthetics), and annual maintenance costs dropped by over 30%. The project passed ISO 9001 and SGS inspections, ensuring lasting quality and compliance.

Top Manufacturer Comparison: Why Choose Sothink PVC Marble Sheet?

| Specification | SothinkDecor | Generic Brand A | Generic Brand B |

|---|---|---|---|

| Thickness (mm) | 2.8 / 3.4 / 5.0 | 2.5 / 3.0 | 2.5 / 4.0 |

| Surface Film | UV Marble Film (120μm, HD print) | PVC printed film (80μm) | Regular PET film |

| Fire Rating | B1 (EN 13501-1) | B1 | B2 |

| Impact Resistance | Up to 43 kJ/m² | 26 kJ/m² | 29 kJ/m² |

| Test Standards | ISO 9001, CE | CE only | None |

| Delivery Time | 7-12 days | 18-30 days | 19-21 days |

| Warranty | 5 Years (written) | 2 Years | 3 Years |

| OEM/Custom Design | Yes, MOQ 200pcs, 500+ patterns available | Limited | Not supported |

Customization Options & Turnkey Solutions

At Sothink, artificial marble sheet solutions are highly customizable:

- Thickness: 1.8mm to 9mm available on request.

- Size: Common: 1220×2440 mm, 1000×2400 mm, or cut-to-size for bedroom pvc marble sheet designs.

- Pattern: Over 500 digitally printed designs (matched to customer sample or photo). 3D textured surface available.

- Surface: Matte, glossy, and natural touch finishes.

- Certification: ISO 9001, SGS, RoHS, FDA-compliant by request.

- Packaging: Carton + pallet, customizable logo printing accepted.

- Lead Time: Production: 5–10 days per order under 5000sqm; Shipping: 12–20 days worldwide.

Delivery, Warranty, and Customer Support

- Delivery cycle: Standard production in 7–12 working days for up to 5000m2; custom projects confirmed by contract.

- Warranty: 5-year product quality guarantee, with after-sale tech support and quick replacement policies.

- Customer Support: 24/7 response, technical consultation, free installation guides, on-site supervision option for projects >1000m2.

- Global Presence: Over 40 countries served, trusted by key real estate, hospitality, and construction names worldwide.

For additional technical resources and industry discussions, please refer to:

-

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >Mar 17 2025

-

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >Mar 13 2025

-

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >Mar 13 2025

-

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >Mar 13 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com