Premium Artificial Marble Sheet | Flexible & Durable Designs

Understanding Artificial Marble Sheets: Industry Trends and Innovations

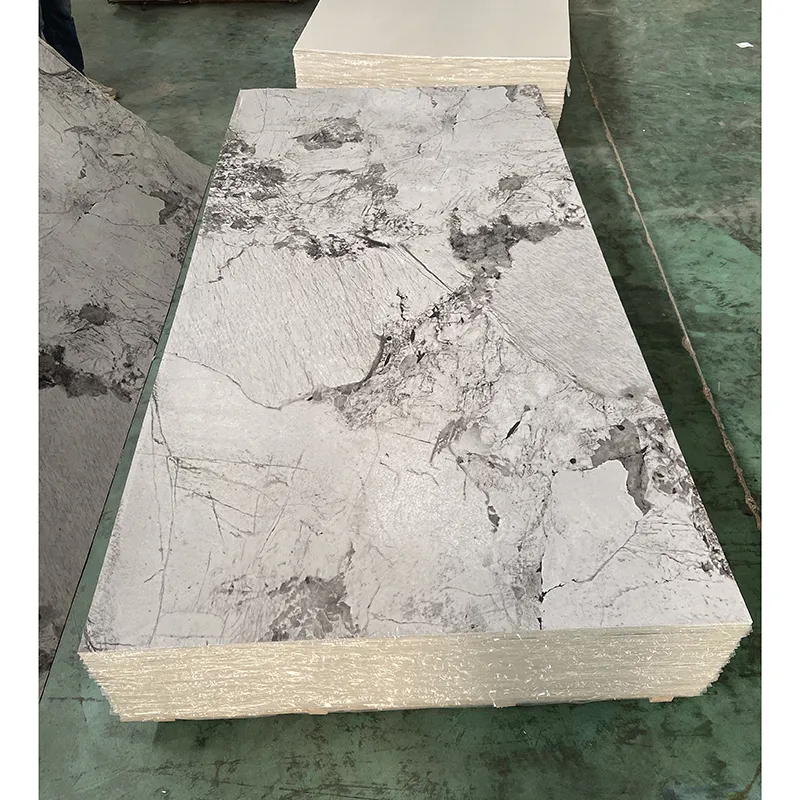

The architectural and interior design industries are witnessing a significant shift towards innovative materials that offer both aesthetic appeal and superior functional performance. Among these, artificial marble sheet stands out as a versatile and cost-effective alternative to natural stone. This engineered material, primarily composed of PVC (Polyvinyl Chloride) and calcium carbonate, perfectly replicates the intricate patterns and luxurious feel of real marble while addressing many of its inherent limitations. Current industry trends highlight a growing demand for durable, lightweight, and easy-to-install surfacing solutions, driving manufacturers to innovate in terms of design replication, environmental sustainability, and enhanced physical properties. The market is increasingly valuing products that can accelerate project timelines and reduce overall costs without compromising on visual quality, making PVC Marble Sheets a preferred choice for a wide array of commercial and residential applications.

Beyond traditional applications, the market for artificial marble sheet is expanding into specialized sectors. For instance, the demand for `bedroom pvc marble sheet designs` is surging as homeowners seek durable yet elegant finishes for their private sanctuaries. Similarly, the commercial sector, including hospitality and retail, actively seeks `flex marble sheet` and `flex pvc marble` for curved surfaces and intricate design elements, demonstrating the material's adaptability. The evolution from rigid panels to flexible sheets underscores a commitment to design freedom and ease of installation. This adaptability, combined with advancements in digital printing and surface treatment technologies, allows for an unprecedented variety of patterns and textures, enabling designers to achieve high-end aesthetics at a fraction of the cost of natural stone.

Advanced Manufacturing Process of PVC Marble Sheets

The production of artificial marble sheet involves a sophisticated multi-stage manufacturing process, ensuring a high-quality, durable, and visually striking end product. Unlike traditional methods such as casting or forging, which are common in metal fabrication, PVC Marble Sheets are produced through advanced extrusion-calendering and laminating techniques. The primary raw materials typically include virgin PVC resin, a high percentage of calcium carbonate powder, and various additives such as stabilizers, lubricants, and pigments. The meticulous formulation of this compound is crucial for achieving the desired physical properties and aesthetic characteristics.

The manufacturing process typically begins with the precise blending of raw materials into a homogeneous mixture. This compound is then fed into an extruder, where it is heated and extruded into a molten sheet. This sheet then undergoes calendering, a process where it passes through a series of heated rollers to achieve the desired thickness and surface smoothness. Following this, a high-definition decorative film, often featuring realistic marble patterns, is laminated onto the PVC substrate. This lamination process, often utilizing advanced adhesive technologies, ensures a strong, permanent bond between the decorative layer and the core. The final stage involves applying a protective UV coating, which provides exceptional scratch resistance, color stability against UV light, and enhanced durability. This UV curing step is vital for extending the product's lifespan and maintaining its aesthetic integrity over time. Rigorous quality control, adhering to standards such as ISO 9001, is implemented at each stage, ensuring consistency in thickness, color, pattern alignment, and overall structural integrity.

Technical Parameters and Performance Data

The superior performance of PVC Marble Sheets is attributed to their carefully engineered technical specifications. Understanding these parameters is crucial for B2B decision-makers in assessing material suitability for specific projects. Key attributes include high density, excellent fire retardancy, and superior resistance to abrasion and common chemicals. The material's inherent moisture resistance makes it ideal for environments prone to humidity, preventing issues like mold and mildew growth that can plague natural materials.

| Parameter | Value/Standard | Description |

|---|---|---|

| Material Composition | Virgin PVC, Calcium Carbonate (70%+) | Ensures durability, stability, and eco-friendliness. |

| Standard Thickness | 2.5mm - 5.0mm (Customizable) | Optimal for various applications, ensuring rigidity. |

| Density | ~1.9 g/cm³ | Contributes to impact resistance and sound insulation. |

| Fire Rating | B1 / Class A (ASTM E84 equivalent) | High resistance to flame spread, critical for public spaces. |

| Abrasion Resistance | ≥ 2000 cycles (EN 13329) | Withstands daily wear and tear in high-traffic areas. |

| Water Absorption | < 0.1% | Virtually waterproof, ideal for wet environments. |

| VOC Emissions | Negligible (Eco-friendly) | Contributes to healthier indoor air quality. |

| UV Stability | Excellent (No significant fading over 5 years) | Maintains color integrity even with sun exposure. |

| Chemical Resistance | Resistant to dilute acids, alkalis, oils | Easy to clean and maintain, resisting common household chemicals. |

These properties collectively ensure that PVC Marble Sheets provide a long service life, typically exceeding 15-20 years under normal indoor conditions, far surpassing the durability and maintenance demands of many conventional materials. For projects requiring specific certifications, such as those related to indoor air quality or specific fire safety regulations, it is crucial to consult product datasheets and relevant international standards like ASTM and ANSI, to ensure compliance. The minimal VOC emissions also make these sheets a preferred choice for sustainable building projects, contributing to LEED certification eligibility in certain contexts.

Diverse Application Scenarios and Technical Advantages

The versatility and robust properties of artificial marble sheet open up a broad spectrum of application scenarios across various sectors. In commercial spaces, these sheets are extensively used for wall cladding in hotel lobbies, retail showrooms, and office receptions, where their aesthetic appeal and low maintenance are highly valued. Their lightweight nature simplifies installation, reducing labor costs and project timelines, a critical advantage for large-scale commercial fit-outs. For healthcare facilities, the non-porous surface of `fake marble sheet` makes it exceptionally hygienic and easy to sterilize, crucial for maintaining clean environments. Similarly, in the hospitality sector, these sheets offer a luxurious finish for bathrooms, kitchen backsplashes, and decorative panels, with the added benefit of being moisture-resistant and durable against daily wear.

Beyond commercial applications, the residential market benefits significantly from the advent of `bedroom pvc marble sheet designs`. Homeowners can achieve sophisticated, high-end marble aesthetics without the prohibitive cost or complex installation of natural stone. The technical advantages extend to various critical aspects:

- Cost-Effectiveness: Significantly lower material and installation costs compared to natural marble.

- Durability: High resistance to impact, scratches, and abrasions, ensuring long-term aesthetic integrity.

- Moisture Resistance: Impervious to water, making it ideal for bathrooms, kitchens, and other moisture-prone areas.

- Ease of Maintenance: Non-porous surface prevents staining and simplifies cleaning; no special sealants required.

- Installation Efficiency: Lightweight and easy to cut, allowing for quick and efficient installation, often over existing surfaces.

- Design Versatility: Available in an extensive range of patterns, colors, and textures, including highly realistic `fake marble sheet` variations.

- Flexibility: Innovations like `flex marble sheet` and `flex pvc marble` enable application on curved surfaces and columns, expanding design possibilities.

Manufacturer Comparison and Customization Solutions

When sourcing artificial marble sheet, selecting the right manufacturer is paramount for ensuring product quality, consistency, and reliable supply. Leading manufacturers distinguish themselves not only by adhering to stringent quality controls like ISO 9001 but also by their capacity for innovation and comprehensive customization services. Factors to consider include: the quality of raw materials used (e.g., virgin PVC vs. recycled content), the precision of their manufacturing lines, the breadth of their product catalog (ranging from standard `fake marble sheet` to specialized `flex marble sheet`), and their commitment to sustainable practices. Companies with significant service years and a proven track record of serving diverse global markets, often indicated by a broad client base and numerous international certifications, generally offer superior trustworthiness.

Customization is a key differentiator in the artificial marble sheet market. Reputable manufacturers offer extensive customization options to meet specific project requirements. This includes:

- Thickness and Size: Ability to produce sheets in various thicknesses (e.g., 2.5mm to 5.0mm) and custom dimensions to minimize waste and optimize installation.

- Pattern and Color Matching: Advanced digital printing allows for precise replication of specific marble patterns, colors, or even bespoke designs provided by clients, ensuring project uniqueness.

- Surface Finishes: Options for high-gloss, matte, or textured finishes to achieve desired aesthetic and tactile qualities.

- Functional Properties: Customization for enhanced properties such as increased fire retardancy, improved UV resistance for outdoor-adjacent applications, or enhanced anti-bacterial surfaces for healthcare environments.

Real-World Application Cases and Client Testimonials

The practical effectiveness and aesthetic impact of artificial marble sheet are best illustrated through successful application cases and direct client feedback. For example, a prominent hotel chain recently utilized `flex pvc marble` for a major renovation of their guest bathrooms and lobby areas. The client reported a 40% reduction in installation time compared to natural stone, alongside significant cost savings. The non-porous surface of the artificial marble sheet has also led to improved hygiene scores and reduced cleaning efforts, a critical operational advantage in the hospitality sector.

Another notable case involved a chain of luxury retail boutiques that opted for `fake marble sheet` for their feature walls and display stands. The client praised the material's ability to perfectly mimic rare marble patterns, creating an upscale ambiance without exceeding budget constraints. The ease of cutting and forming the sheets also allowed for intricate design details that would have been prohibitively expensive or structurally challenging with natural stone. Our company, Sothink Decor, has over 15 years of experience serving clients across more than 50 countries, consistently delivering high-quality PVC Marble Sheet solutions. We maintain an ISO 9001 certified quality management system, ensuring every batch meets rigorous international standards. Our dedicated customer support team is available 24/7 to address any technical queries or project-specific needs, reinforcing our commitment to client success and satisfaction.

FAQ, Delivery, and Warranty Information

Frequently Asked Questions (FAQ)

Q: Is artificial marble sheet suitable for outdoor use?

A: While artificial marble sheet possesses excellent UV stability, it is primarily designed for indoor applications to ensure optimal performance and longevity. Continuous exposure to extreme weather conditions may affect its long-term integrity, though specialized exterior-grade variants are emerging.

Q: How do I clean and maintain PVC Marble Sheets?

A: Maintenance is remarkably simple. A damp cloth with mild soap or a neutral cleaner is sufficient for daily cleaning. Avoid abrasive cleaners or harsh chemicals, which can damage the UV protective layer. The non-porous surface prevents staining, eliminating the need for sealing.

Q: Can these sheets be installed over existing tiles or drywall?

A: Yes, one of the significant advantages of artificial marble sheet is its versatility for overlay installation. As long as the existing surface is clean, dry, and structurally sound, these lightweight sheets can be directly adhered using appropriate construction adhesives, saving significant demolition and preparation time.

Delivery Cycle and Quality Assurance

Our typical production lead time for standard artificial marble sheet orders ranges from 7 to 15 business days, depending on order volume and specific customization requirements. For large-scale or highly customized projects, a detailed production and delivery schedule will be provided upon order confirmation. We ensure secure packaging for all shipments to prevent damage during transit. Every batch undergoes stringent quality control inspections, adhering to international standards to guarantee consistency in product specifications. We provide a comprehensive 10-year limited warranty against manufacturing defects for our PVC Marble Sheet products, reflecting our confidence in their durability and performance. Our commitment to quality extends beyond delivery, with dedicated after-sales support to assist clients with any queries or concerns regarding product installation or long-term performance.

References and Further Reading

- Polymer Science and Technology: A Comprehensive Guide to Plastics, Rubbers, Blends, Composites, and Fibers.

- The Principles of Polymer Engineering.

- Advances in Building Materials: Structural, Functional and Sustainable Solutions.

- Architectural Materials for Interior Design: An Overview.

-

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >Aug 05 2025

-

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >Aug 05 2025

-

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >Aug 05 2025

-

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >Aug 05 2025

-

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >Aug 05 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com