Flex Artificial Marble Sheet: Durable, Stylish, Easy Install

The Rise of Artificial Marble Sheet in Modern Design

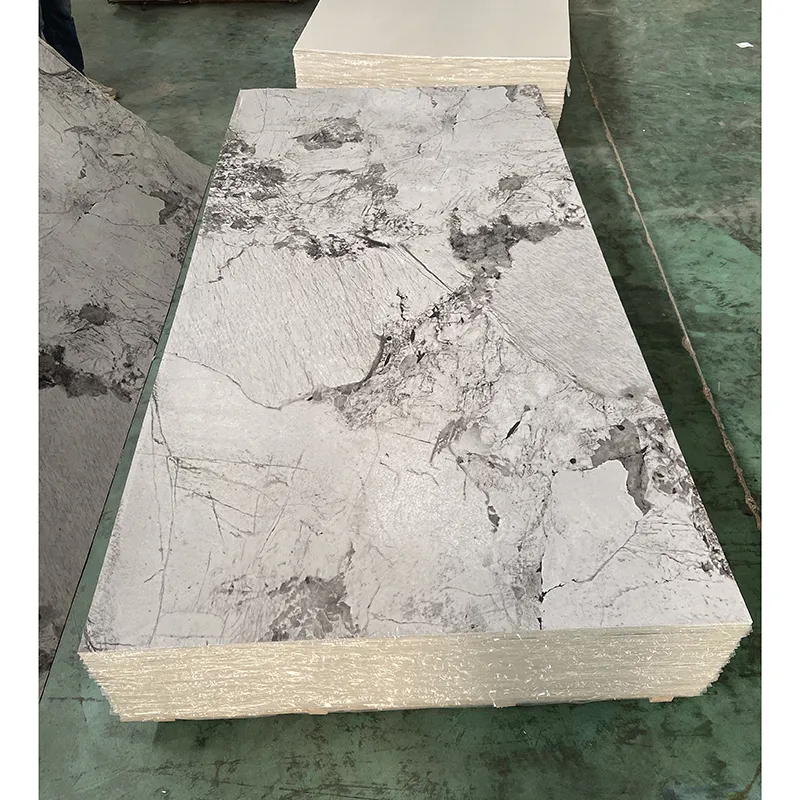

In the rapidly evolving landscape of interior and exterior design, the demand for versatile, durable, and aesthetically pleasing materials has never been higher. Among the leading innovations addressing this need is the artificial marble sheet. This engineered material, primarily PVC Marble Sheet, has emerged as a superior alternative to natural stone, offering unparalleled design flexibility, cost-effectiveness, and ease of installation. Its ability to replicate the intricate patterns and luxurious feel of natural marble, without the inherent fragilities and high maintenance, makes it a preferred choice for a wide array of B2B applications, from commercial establishments to residential projects.

The industry trend clearly indicates a shift towards sustainable, high-performance materials. Artificial marble sheets align perfectly with this trend, providing a lightweight yet robust solution that significantly reduces installation time and labor costs. Unlike traditional materials, they offer exceptional water resistance, anti-bacterial properties, and resistance to scratches and impact, ensuring a longer service life and lower lifetime costs. This makes them an attractive proposition for architects, designers, and contractors seeking efficient and reliable surfacing options for large-scale projects.

Understanding PVC Marble Sheet: The Core of Artificial Marble Technology

At the heart of the modern artificial marble sheet lies advanced PVC (Polyvinyl Chloride) technology. Sothink Decor's PVC Marble Sheets are crafted using a sophisticated multi-layer co-extrusion process, ensuring exceptional structural integrity and aesthetic fidelity. The core material is virgin PVC resin, combined with calcium carbonate and other proprietary additives. This blend results in a material that is not only robust but also eco-friendly, free from harmful substances like formaldehyde.

A typical PVC Marble Sheet comprises several layers: a virgin PVC base layer for stability, a printed decorative film that provides the realistic marble pattern, and a high-wear UV coating layer for protection. This unique composition gives the sheet its characteristic properties, including excellent water resistance, high impact strength, and ease of maintenance. The superior UV coating ensures color stability and resistance to fading, even in environments with significant light exposure. This meticulous layering process sets PVC Marble Sheets apart as a premium fake marble sheet option, delivering both beauty and enduring performance.

The Manufacturing Process: Precision and Quality Control

The production of high-quality artificial marble sheet involves a meticulously controlled manufacturing process, distinct from traditional stone fabrication. It begins with the precise blending of raw materials – PVC resin, calcium carbonate, and various stabilizers and pigments. This mixture is then fed into specialized extruders, where it is heated and extruded into a continuous sheet under high pressure and temperature. This extrusion forms the rigid core of the PVC sheet, ensuring uniform density and structural integrity.

Following the core extrusion, a high-definition decorative film, typically printed with realistic marble patterns, is laminated onto the PVC base. This process often involves hot-stamping or thermal lamination techniques to ensure a strong, bubble-free bond. The final and crucial step is the application of a UV-cured coating. This protective layer is applied and then cured instantly under ultraviolet light, resulting in a highly durable, scratch-resistant, and glossy or matte surface. Rigorous quality control measures are integrated at every stage, from raw material inspection to final product testing. Products are subjected to tests aligning with international standards such as ISO 9001 for quality management and ASTM standards for material properties, guaranteeing consistent performance and adherence to specifications. This ensures each sheet of flex marble sheet meets stringent quality benchmarks, providing long-term reliability for diverse applications.

Technical Specifications & Performance Advantages

The appeal of artificial marble sheet extends beyond its aesthetic value, deeply rooted in its superior technical parameters and performance advantages. These sheets are engineered to surpass the limitations of natural stone, offering enhanced durability, simpler maintenance, and improved safety features.

Key Technical Parameters of PVC Marble Sheet

| Parameter | Specification | Typical Value (Sothink Decor) |

|---|---|---|

| Material Composition | Virgin PVC Resin + Calcium Carbonate (70%) + Additives | High-grade Virgin PVC, |

| Sheet Thickness | 1.8mm - 6.0mm | Standard: 3.0mm, Custom: Available |

| Standard Dimensions | 1220mm x 2440mm (4ft x 8ft) | Available |

| Surface Finish | High Gloss, Matte, UV Coated | > 95 Gloss Units (High Gloss) |

| Density | ~2.0 g/cm³ | 2.05 ± 0.05 g/cm³ |

| Water Absorption | < 0.1% (24 hrs) | Negligible (ASTM D570-98) |

| Fire Rating | B1 (Flame Retardant) | Class B1 (GB 8624-2012) |

| Impact Strength | High | Excellent (ISO 179) |

| Service Life | Typically 10-15 years indoors | 15+ years under normal conditions |

These robust specifications underpin the versatility of flex pvc marble sheets, making them suitable for high-traffic areas and environments demanding stringent hygiene, such as healthcare facilities and commercial kitchens, where their anti-bacterial properties are invaluable. Furthermore, their lightweight nature significantly reduces structural load and simplifies transportation, contributing to overall project efficiency and cost savings.

Diverse Applications Across Industries

The adaptability of artificial marble sheet makes it a preferred material across a broad spectrum of applications, far beyond traditional decorative uses. Its unique properties allow it to thrive in environments where natural stone might falter, offering aesthetic appeal alongside functional superiority.

- Commercial & Hospitality: Ideal for hotel lobbies, restaurants, retail spaces, and corporate offices. Its sophisticated appearance elevates interiors, while its durability handles high foot traffic effortlessly.

- Residential Interiors: Perfect for accent walls, kitchen backsplashes, bathroom cladding, and even exquisite bedroom pvc marble sheet designs. Its water resistance makes it particularly suitable for wet areas without concerns of mold or mildew.

- Healthcare Facilities: The non-porous and anti-bacterial surface of PVC marble sheets contributes to hygienic environments, making them suitable for clinics, laboratories, and patient rooms where cleanliness is paramount.

- Public Spaces: Used in airports, subway stations, and educational institutions, these sheets provide robust and easy-to-maintain surfaces that withstand significant wear and tear.

- Exhibition & Event Booths: Their lightweight nature and ease of installation make them an excellent choice for temporary structures and exhibition stands, providing a high-end look with minimal effort.

In all these scenarios, the quick installation, minimal waste generation, and competitive pricing of flex marble sheet offer significant advantages to B2B clients, optimizing project timelines and budgets without compromising on design or quality.

Ensuring Trust: Quality Assurance & Customer Support

Trust is paramount in B2B relationships. Sothink Decor's commitment to quality for its artificial marble sheet products is backed by comprehensive certifications and a robust support infrastructure. Our manufacturing facilities adhere strictly to ISO 9001 quality management systems, ensuring every production batch meets international benchmarks for consistency and performance. Additionally, our products undergo independent SGS testing for various parameters, including fire resistance, formaldehyde emission, and heavy metal content, confirming their safety and environmental compliance.

Commitment to Our Clients

- Quality Guarantee: We offer a comprehensive 10-year limited warranty on our PVC Marble Sheets for indoor applications, covering manufacturing defects and significant material degradation under normal use.

- Delivery & Logistics: With efficient supply chain management and strategic partnerships with logistics providers, we ensure reliable and timely delivery worldwide. Typical lead times are 15-20 days for standard orders, with expedited options available for urgent projects.

- Customization & OEM/ODM: Beyond standard designs, we provide extensive customization options for patterns, thicknesses, and finishes, catering to unique project requirements. Our robust R&D team supports OEM and ODM partnerships.

- Dedicated Customer Support: Our expert sales and technical support teams are available 24/7 to assist with product selection, technical queries, installation guidance, and after-sales service, ensuring a seamless experience from inquiry to project completion.

Frequently Asked Questions (FAQ)

Q: How does artificial marble sheet compare to natural marble in terms of cost and maintenance?

A: PVC Marble Sheets are significantly more cost-effective both in initial purchase and long-term maintenance. They are lighter, reducing shipping and installation costs. Unlike natural marble, they don't require sealing, are stain-resistant, and can be cleaned with simple soap and water, drastically cutting down on upkeep expenses and time. This makes them a superior fake marble sheet option.

Q: Are PVC Marble Sheets suitable for outdoor use?

A: While our PVC Marble Sheets exhibit excellent UV stability, they are primarily designed for indoor applications. Prolonged direct exposure to harsh outdoor elements might affect their longevity and aesthetic over extended periods. For specific outdoor project requirements, please consult with our technical team for specialized recommendations or alternative materials.

Q: What are the installation requirements for flex pvc marble sheets?

A: Installation is relatively straightforward. Sheets can be directly applied to most smooth, dry, and clean surfaces using construction adhesive. They can be cut with standard woodworking tools, making customization on-site easy. Minimal tools and expertise are required compared to natural stone installation, contributing to faster project completion. We provide detailed installation guides and technical support.

Q: What is the environmental impact of PVC Marble Sheets?

A: Our PVC Marble Sheets are manufactured using virgin PVC resin, ensuring no recycled content that could introduce impurities. They are formaldehyde-free and low VOC, contributing to healthier indoor air quality. PVC is a highly recyclable thermoplastic, and our production processes are designed to minimize waste and energy consumption, aligning with modern sustainability practices.

References and Further Reading

- European Council of Vinyl Manufacturers (ECVM) - Provides detailed information on PVC production, applications, and environmental performance.

- American Society for Testing and Materials (ASTM International) - Source for standards related to plastic materials and construction products.

- International Organization for Standardization (ISO) - Global standards for quality management and environmental management systems in manufacturing.

- Journal of Vinyl and Additive Technology (Wiley Online Library) - Peer-reviewed articles on the science and engineering of vinyl polymers.

-

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >Aug 05 2025

-

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >Aug 05 2025

-

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >Aug 05 2025

-

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >Aug 05 2025

-

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >Aug 05 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com