Premium WPC Fence Panels for Sale | Durable & Low Maintenance

The Rise of WPC Fence Panels in Modern Architecture and Landscaping

In today's rapidly evolving construction and landscaping industries, the demand for sustainable, durable, and aesthetically pleasing materials is at an all-time high. Among the innovative solutions gaining significant traction are wpc fence panels for sale. These composite materials, combining the best attributes of wood and plastic, offer an unparalleled blend of environmental responsibility, low maintenance, and design versatility. This comprehensive guide delves into the intricate world of Wood Plastic Composite (WPC) fence panels, exploring their manufacturing excellence, technical prowess, diverse applications, and the inherent advantages that make them a preferred choice for discerning B2B clients and project developers. We will also touch upon the broader WPC ecosystem, including how reputable wpc wall panel wholesalers contribute to a robust supply chain, ensuring the availability of high-quality WPC products across various segments.

The market for WPC products, including both fencing and structural elements like a wpc wallpanel, is experiencing exponential growth, driven by increasing awareness of ecological footprints and the need for long-lasting solutions. From residential boundaries to large-scale commercial enclosures, WPC fence panels provide a sophisticated and reliable alternative to traditional wood or metal fences. Their resistance to rot, decay, insects, and harsh weather conditions positions them as a superior investment, reducing long-term costs associated with maintenance and replacement. Understanding the underlying technology and material science behind these panels is crucial for making informed procurement decisions that align with project specifications and sustainability goals.

The Precision Craft of WPC Fence Panel Manufacturing

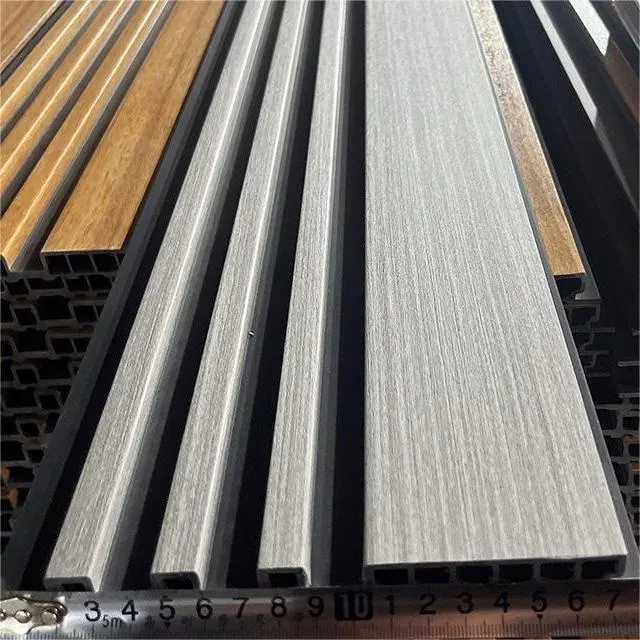

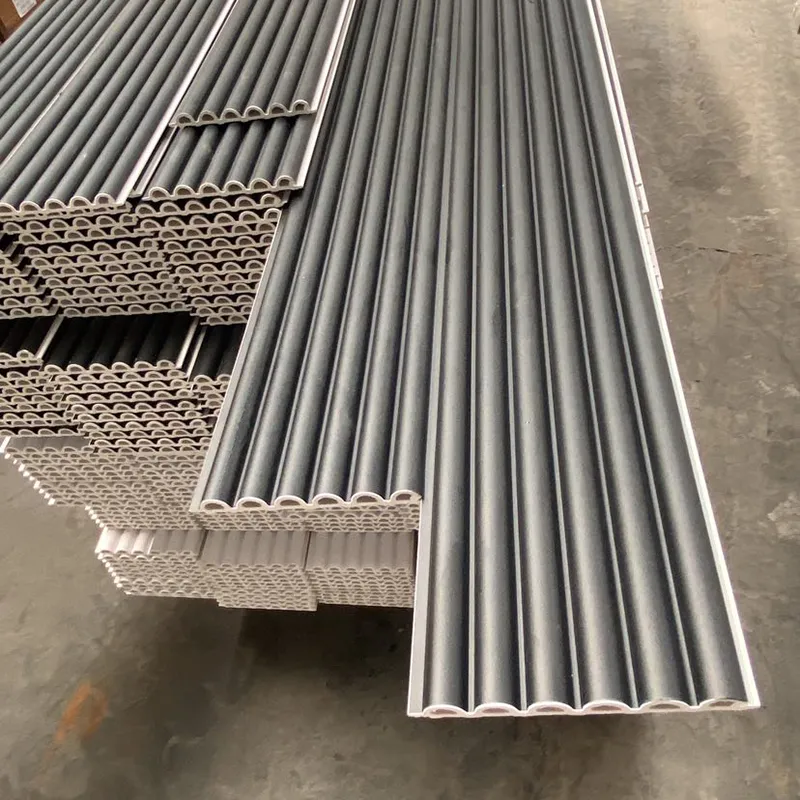

The production of wpc fence panels for sale is a testament to advanced material science and precision engineering. The core composition typically involves a blend of recycled wood fibers (often sawdust, wood flour, or wood chips) and recycled plastic polymers (such as HDPE, LDPE, PP, or PVC), augmented with various additives including UV stabilizers, coupling agents, lubricants, and foaming agents. This carefully proportioned mixture dictates the panel's strength, durability, and aesthetic finish. The primary manufacturing process is extrusion, where the composite mixture is heated and then forced through a die to create the desired profile of the fence panel. This method ensures a consistent density and shape throughout the product, crucial for structural integrity and ease of installation.

Post-extrusion, WPC panels undergo a cooling process, often followed by surface treatments like brushing, sanding, or embossing to mimic natural wood grain, or co-extrusion for enhanced durability and color stability. Quality control is paramount at every stage. Products are rigorously tested against international standards such as ISO 9001 for quality management systems and ISO 14001 for environmental management. Furthermore, specific performance tests like ASTM D6109 for flexural properties, ASTM D7032 for fire resistance, and EN 15534 for general WPC profiles are critical. These stringent checks ensure that each wpc wall panel or fence component meets predefined specifications for strength, weather resistance, and longevity, often boasting a service life exceeding 15-20 years, significantly longer than untreated timber. WPC's inherent resistance to rot, fungal decay, and termites makes it ideal for various environments, from residential backyards to large-scale industrial perimeters in sectors like urban development and leisure facilities, where its low-maintenance nature translates into substantial long-term cost savings.

Detailed Specifications of WPC Fence Panels

When sourcing wpc fence panels for sale, understanding the key technical parameters is vital for ensuring compatibility with project requirements and long-term performance expectations. These parameters directly influence the panel's structural integrity, aesthetic appeal, and suitability for specific environmental conditions. Below is a detailed table outlining typical specifications for high-quality WPC fence panels available on the market, offering insights into what B2B purchasers should prioritize.

The robust nature of these specifications illustrates why WPC fence panels are increasingly favored over conventional materials. Their ability to withstand extreme temperatures, resist moisture absorption, and maintain color integrity over years makes them a highly durable and cost-effective solution for various outdoor applications.

Versatile Applications and Evolving Industry Trends

The versatility of wpc fence panels for sale extends across a wide spectrum of application scenarios, driven by ongoing innovations in design and material science. Initially popular for residential privacy fences, their adoption has expanded significantly into commercial, public, and even specialized industrial settings. Common applications include perimeter fencing for private residences, decorative garden barriers, commercial property demarcation, and robust security fences for public parks or leisure facilities. Their aesthetic flexibility also makes them ideal for creating cohesive exterior designs when paired with other WPC products, such as outdoor decking or wpc wallpanel systems used in exterior facades.

Current industry trends highlight a growing emphasis on smart WPC solutions, integrating features like enhanced fire resistance for urban applications or specialized coatings for extreme weather conditions. The demand for eco-friendly building materials continues to propel the WPC market forward, as manufacturers refine processes to utilize higher percentages of recycled content without compromising performance. Furthermore, customization is a significant trend, with B2B clients seeking specific colors, textures, and panel profiles to match unique architectural visions. Manufacturers like Sothink Decor, known for their WPC Interior Wall Panel offerings, are increasingly expanding their product lines to cater to the diverse requirements of the outdoor WPC market, establishing themselves as key wpc wall panel wholesalers who understand the nuanced needs of various construction projects. This comprehensive approach ensures that whether it's for a simple residential fence or a complex commercial enclosure, there's a WPC solution available that combines functionality with sustainable design principles.

Why Choose WPC: Unmatched Advantages and Benefits

The decision to invest in wpc fence panels for sale is underpinned by a compelling array of technical advantages and long-term benefits that significantly outweigh traditional fencing materials. These advantages translate directly into reduced lifecycle costs, enhanced project longevity, and greater environmental responsibility.

- Superior Durability & Longevity: Unlike wood, WPC is immune to rot, decay, and insect infestation (e.g., termites). Its composite nature provides exceptional resistance to moisture, UV radiation, and extreme temperature fluctuations, ensuring a lifespan of 15-25 years without splintering or warping.

- Minimal Maintenance: WPC fence panels require no painting, staining, or sealing. A simple occasional cleaning with soap and water is sufficient to maintain their appearance, drastically reducing maintenance labor and material costs over time. This is a significant advantage for large-scale commercial or public projects.

- Eco-Friendly Composition: Manufactured from recycled wood fibers and plastics, WPC helps divert waste from landfills and reduces the reliance on virgin timber. This makes it an excellent choice for LEED-certified projects and companies committed to sustainable practices.

- Aesthetic Versatility: Available in a wide range of colors, textures, and finishes, WPC panels can mimic the look of natural wood or provide contemporary sleek designs. This flexibility allows architects and designers to achieve specific aesthetic goals without compromising on performance. A consistent design language can be achieved by also integrating wall panel wpc for interior or exterior architectural elements.

- Safety and Installation Ease: WPC does not splinter, making it safer to handle and install. Its consistent dimensions and pre-fabricated nature simplify installation, reducing labor time and potential on-site errors.

These core advantages highlight WPC's position as a premium material for fencing solutions, delivering both economic efficiency and environmental responsibility.

Choosing the Right Supplier: Manufacturer Comparison & Customization

Selecting a reliable manufacturer for wpc fence panels for sale is as crucial as understanding the product itself. The market is populated by various suppliers, each offering different levels of quality, service, and customization. B2B purchasers should evaluate potential partners based on their manufacturing capabilities, adherence to international standards, product range, and commitment to customer service and technical support.

Leading wpc wall panel wholesalers and fence panel manufacturers distinguish themselves through several key attributes. They typically possess ISO 9001 and ISO 14001 certifications, ensuring robust quality management and environmental practices. Furthermore, they should offer comprehensive technical data sheets (TDS) and material safety data sheets (MSDS) for all products, confirming compliance with industry benchmarks and regulatory requirements. Companies that invest in R&D are also likely to provide innovative solutions, such as co-extruded WPC panels for superior UV and scratch resistance, or fire-retardant formulations suitable for commercial applications.

Customization is a pivotal aspect for large-scale projects. Reputable suppliers will offer bespoke solutions, allowing clients to specify unique dimensions, colors, textures, and even composite ratios to meet precise design and performance requirements. This includes the ability to match existing architectural elements or specific branding guidelines. For instance, if a project requires a seamless integration of outdoor fencing with indoor finishes, a supplier who also provides WPC Interior Wall Panel products and acts as a comprehensive wall panel wpc supplier offers a significant advantage in terms of design consistency and streamlined procurement. Prioritizing manufacturers with a proven track record, extensive product testing, and strong logistical capabilities ensures a smooth project execution from order to installation.

Assurance of Quality: Certifications and Real-World Performance

Authoritativeness in the WPC industry is built upon a foundation of rigorous testing, certifications, and demonstrated real-world performance. When evaluating wpc fence panels for sale, B2B stakeholders should look for manufacturers who transparently provide evidence of compliance with international and regional standards.

- ISO Certifications: ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System) are baseline indicators of a manufacturer's commitment to consistent quality and sustainable practices.

- ASTM & CE Standards: Compliance with American Society for Testing and Materials (ASTM) standards (e.g., for mechanical properties, weatherability) and CE marking (for European market compliance) verifies the product's fitness for purpose and safety.

- Test Data & Reports: Reputable suppliers will readily share third-party test reports detailing results for tensile strength, impact resistance, fire rating, slip resistance (if applicable for other WPC products), and accelerated weathering tests. These data points provide objective proof of performance.

Case Study Example: Commercial Property Perimeter A leading commercial real estate developer recently opted for WPC fence panels for a new office park in a high-humidity coastal region. Traditional wood fencing had previously succumbed to rot and insect damage within five years. By selecting a supplier with ISO 9001 certification and a product with verified low water absorption (<0.5%), the developer achieved a durable, aesthetically consistent perimeter that has remained pristine for over seven years with zero maintenance beyond occasional cleaning. This tangible success story underscores the long-term value and reliability offered by high-quality WPC solutions. The positive experience also led them to consider wpc wallpanel systems for an upcoming interior renovation project, demonstrating the cross-application benefits of reliable WPC suppliers.

Trust and Support: Your Partner in WPC Solutions

Building trust with B2B clients extends beyond product quality to encompass comprehensive support, transparent processes, and clear commitments. When considering wpc fence panels for sale, look for suppliers who prioritize customer satisfaction through robust service offerings.

Frequently Asked Questions (FAQ)

Q1: Are WPC fence panels truly eco-friendly?

A1: Yes, they are. WPC is manufactured from recycled wood waste and plastics, reducing landfill burden and conserving natural timber resources. They are a sustainable alternative in construction.

Q2: What is the typical lead time for a bulk order of WPC fence panels?

A2: Lead times can vary based on order volume and customization requirements, but generally range from 20-45 business days for standard profiles. Expedited options may be available for urgent projects. Specific delivery schedules are provided upon order confirmation.

Q3: How does the warranty work for WPC products?

A3: Reputable manufacturers offer warranties typically ranging from 10 to 25 years against manufacturing defects, rot, decay, and significant color fading. Detailed warranty terms and conditions are always provided with your quotation and purchase agreement.

Q4: Can I get samples before placing a large order?

A4: Absolutely. Most suppliers, including key wpc wall panel wholesalers, understand the importance of physical samples for material evaluation. We encourage requesting samples to assess color, texture, and quality firsthand.

Delivery and Logistics

Efficient delivery and robust logistics are critical for B2B projects. Suppliers should offer flexible shipping options, including sea freight and potentially air freight for smaller, urgent components. Clear communication regarding shipping schedules, tracking, and customs documentation is paramount. Working with a global wpc wallpanel supplier often means leveraging their established logistics networks for smooth international shipments.

Customer Support and After-Sales Service

A strong customer support team capable of providing technical assistance, installation guidance, and troubleshooting is invaluable. Post-purchase support ensures that any challenges encountered during installation or over the product's lifespan are addressed promptly and effectively, safeguarding your investment in wpc fence panels for sale. This includes providing detailed installation manuals and access to expert advice.

Conclusion: The Future of Fencing is WPC

The increasing adoption of wpc fence panels for sale marks a significant shift in how we approach outdoor construction and design. Their superior blend of durability, minimal maintenance, environmental sustainability, and aesthetic flexibility positions them as the material of choice for discerning professionals and forward-thinking projects. As the demand for responsible and long-lasting building solutions grows, WPC technology continues to evolve, promising even greater innovations. By partnering with reputable manufacturers and leveraging the comprehensive support they offer, B2B clients can confidently invest in WPC fence panels, securing a solution that delivers exceptional value, performance, and peace of mind for decades to come. Whether you're considering a simple boundary or a complex architectural statement, the robust and versatile nature of WPC stands ready to meet the challenge.

References

- ASTM International. (n.d.). _Standards for Plastic and Wood-Plastic Composite Products._ Retrieved from [Example: www.astm.org/standards/d7032.htm]

- European Committee for Standardization. (n.d.). _EN 15534: Wood Plastic Composites (WPC) - Profiles and Boards._ Retrieved from [Example: www.cencenelec.eu]

- International Organization for Standardization. (n.d.). _ISO 9001: Quality Management Systems - Requirements._ Retrieved from [Example: www.iso.org/iso-9001-quality-management.html]

- Plastics Industry Association. (n.d.). _Recycling & Sustainability in Plastics._ Retrieved from [Example: www.plasticsindustry.org/sustainability]

-

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >Aug 05 2025

-

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >Aug 05 2025

-

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >Aug 05 2025

-

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >Aug 05 2025

-

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >Aug 05 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com