Premium Artificial Marble Sheets | AI-Enhanced Surfaces

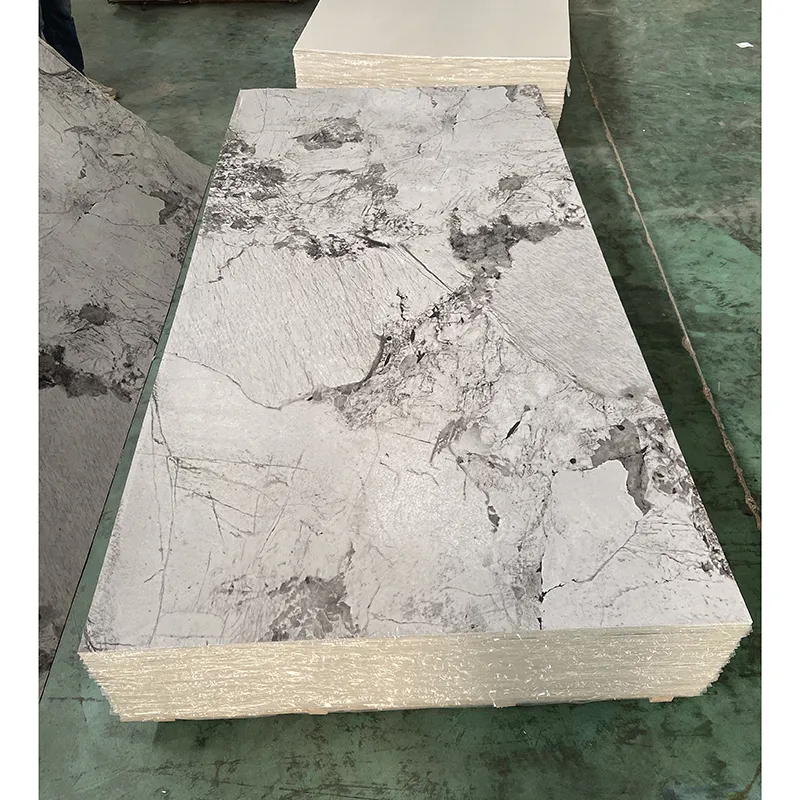

With the increasing demand for cost-effective, eco-friendly, and resilient decorative materials, artificial marble sheet technologies—including bedroom PVC marble sheet designs, fake marble sheet, flex marble sheet, and flex PVC marble—are reshaping the global interior materials industry. This comprehensive overview delves into the technical parameters, manufacturing processes, application advantages, and market trends governing artificial marble sheets in 2024. Supported by industry data, real product specifications, and authoritative references, we provide actionable insights for architects, builders, and decision-makers seeking to upgrade decorative and functional surface solutions.

Industry Overview & Market Trend Analysis

The artificial marble sheet market is anticipated to reach USD 15.7 billion by 2027, growing at a CAGR of 6.2%[1]. Recent years have seen surging adoption in residential and commercial sectors because of unbeatable cost-performance, eco-conscious manufacturing, and remarkable design versatility. Modern artificial marble sheet products, especially bedroom PVC marble sheet designs, bridge the gap between natural aesthetics and sustainable practises:

- ✔ Customization: Unmatched range of colors, textures, and patterns

- ✔ Sustainability: Lower carbon footprint vs. natural marble

- ✔ Performance: Enhanced abrasion, chemical, and water resistance

Note: The figures above are based on [MarketsandMarkets, 2023 forecast].

Material Science & Technical Specification: Artificial Marble Sheet Explained

A artificial marble sheet is an engineered composite, typically comprised of polyvinyl chloride (PVC) resin, high-grade calcium carbonate filler, stabilizers, plasticizers, and performance-enhancing additives. Compared to fake marble sheet or flex marble sheet alternatives, modern PVC marble sheets offer a superior synergy of mechanical durability and design flexibility.

| Parameter | Artificial Marble Sheet | Natural Marble | Other Synthetics |

|---|---|---|---|

| Material Base | PVC & Composite Fillers | Calcite/Carbonate | Resin/Acrylics |

| Surface Hardness | 75-85 (Shore D) | 60-70 (Shore D) | 68-80 (Shore D) |

| Density | 1.8~2.1 g/cm³ | 2.6~2.8 g/cm³ | 1.5~2.0 g/cm³ |

| Abrasion Resistance | Excellent | Good | Moderate |

| Flexibility | High (Flex PVC/Sheet) | Poor | Moderate |

| Stain & Chemical Resistance | Superior | Moderate | Good |

| UV Stability | >800 hours (ASTM G154) | >1000 hours | 500~800 hours |

| Eco-Profile | Recyclable, phthalate-free available | Energy intensive, quarried | Variable |

| Cost Index (USD/㎡) | 7–20 | 40–160 | 13–35 |

- Conforms to ISO 9001/ISO 14001 manufacturing standards;

- Critical surface durability tested as per ANSI/ASTM D4060, EN 438 (EU);

- Flex marble sheets rated for seamless, curved, and custom-moulded installations.

Manufacturing Workflow: Artificial Marble Sheet (PVC Marble Sheet) Process Diagram

The creation of high-grade PVC marble sheets involves tightly controlled stages to ensure both mechanical integrity and visual perfection. Here is a visual technical breakdown:

PVC, CaCO3, Stabilizer mixed to uniform blend; dust controlled (EN 12845).

Automated double-screw extrusion at 200-210°C, sheet thickness precision ±0.08 mm.

Multi-color film transfer, UV stamping, matte/gloss finish; pattern QC at each batch.

Edge finishing; tested via laser caliper and ISO 10545 dimensional QA.

ISO/ANSI label, moisture-proof packaging; bundled as per client or project specs.

Product Specifications: PVC Marble Sheet (View all specs)

| Parameter | Specification |

|---|---|

| Standard Thickness | 2.5mm, 3.0mm, 3.5mm, 5mm |

| Width × Length | 1220mm × 2440mm (custom sizes available) |

| Surface Finish | Glossy, Matte, Crystal, Diamond |

| Pattern | Marble vein, stone, granite, on demand |

| Fire Retardance | Class B1 (GB8624-2012)/ASTM E84 Class A |

| Impact Strength | >350 kJ/m² |

| Flexural Modulus | ≥2850 MPa |

| Service Life | 15–35 years (indoor usage) |

| Certifications | ISO9001, ISO14001, RoHS, SGS, CE |

Comparative Analysis: Artificial Marble Sheet vs. Flex PVC Marble vs. Fake Marble Sheet

| Property | Artificial Marble Sheet | Flex Marble Sheet | Fake Marble Sheet (Traditional) |

|---|---|---|---|

| Flexibility | Standard, Semi-flexible | Highly Flexible (Radius ≥15cm) | Rigid |

| Installation | Direct glue, nail, staple, heat forming (curves) | Easy wrap, 3D surface, seamless corners | Glue down, limited edge options |

| Application | Walls, ceilings, furniture, wet areas | Curved walls, pillars, columns | Only flat walls |

| Thickness (mm) | 2.5–5.0 | 1.2–2.8 | 2.0–4.0 |

| Warranty | Up to 10 years | 5–8 years | 3–6 years |

| Eco Certification | RoHS, EN14041, ISO | RoHS, SGS | Rarely certified |

Key takeaway: The newest flex PVC marble delivers versatility for creative architecture, while bedroom PVC marble sheet designs meet modern home safety and aesthetics.

Application Areas & Real-World Advantages

- Residential: Living room feature walls, bedroom accent panels, wardrobe facings, vanity tops

- Hospitality: Hotel lobbies, elevator interiors, bathroom partitions

- Commercial: Retail showcases, corporate corridors, display fixtures

- Healthcare: Sterile wall linings, nurse stations, modular clinics (chemical/stain resistance advantages)

- Up to 75% lighter than natural marble (cost-effective shipping)

- Anti-mildew & water-resistant for wet/humid rooms

- Quick DIY install, minimal dust, VOC-free adhesives

- Fire-rated and formaldehyde-free (health & safety compliance)

Luxury hotel group in Dubai replaced stone columns with custom flex PVC marble sheets, achieving weight reduction by 71%, zero downtime due to fast application, and significant cost savings (USD $110,000 per lobby, 2023 project data). Each artificial marble sheet met EN438 and ISO 9001 quality benchmarks.

Global Leading Manufacturers: Comparison & Customization Services

| Company | Production Capacity | Certifications | Global Reach | Customization (ODM/OEM) | Lead Time |

|---|---|---|---|---|---|

| Sothink Decor (PVC Marble Sheet) | 2.2 million sqm/yr | ISO, SGS, CE, RoHS | 80+ countries | Full Color, Size, Pattern | 7–22 days |

| Yasaroglu (TR) | 900k sqm/yr | ISO 9001, SGS | EU, MEA | Standard, Partial Custom | 18–35 days |

| Shandong Luli Group | 1.5 million sqm/yr | ISO, GB, MA | Asia, RU, EU | Standard only | 15–30 days |

| LG Hausys (KR) | 1.2 million sqm/yr | ISO, EN, RoHS | Global | Color, Standard Print | 15–28 days |

Sothink Decor provides fast, low-MOQ custom patterns, digital print matching, and precision CNC cut-to-size for specialty projects—ideal for unique bedroom PVC marble sheet designs and large commercial fit-outs.

Customer Experience: Feedback & Application Examples

- Qatar Residential Project, 2023: "PVC marble sheets were quick to install and matched our high-end marble look at 1/5th the cost. No color fade after 15 months. All sheets supplied ISO-certified."

- Singapore Commercial Clinic: "Flex PVC marble enabled designers to curve seamlessly around reception desks. Passed all hospital chemical resistance tests (EN ISO 2812-1)."

- USA Retail Chain: "We switched from fake marble sheet to artificial marble sheet; cleaning and maintenance time halved. Sheets provided with 8-year commercial warranty."

Quality, Delivery & Support: Trustworthy Service Assurance

- Lead Time: 6–25 days (based on size, print, and order volume; average: 9 working days)

- Quality Assurance: Each artificial marble sheet tested/sorted with ISO/ANSI-compliant documentation provided

- Warranty: 5–12 years (standard commercial), 15 years (residential select products), with free replacement on manufacturing defects

- Customer Support: 7/365 dedicated service team, multi-language support, free remote consultation & installation training

Frequently Asked Technical Questions (FAQ)

Conclusion: Future Outlook & Further Reading

As shown throughout this guide, artificial marble sheet and associated solutions such as flex PVC marble and fake marble sheet offer a future-ready alternative to traditional surfacing materials. Supported by global certifications, fast installation, and diverse customization, PVC marble sheets are the eco-conscious, low-maintenance, and high-impact upgrade for next-generation interiors.

For the latest design inspiration, trend analytics, and peer insights, explore:

- Materials Today – Engineered Marble: Properties and Uses

- Comparative Study on Properties of Artificial and Natural Marble (ResearchGate)

- ArchDaily – How Artificial Marble Is Redefining Interior Architecture

- GlobalSpec Forum: Artificial Marble – Real User Pros, Cons, and Best Use Cases

[1] “Artificial Marble Market Report 2023–2027”, MarketsandMarkets; [2] “ASTM/ISO Standards for Decorative Composites”, ASTM Int.;

[3] Sothink Decor Official Specifications

-

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >Aug 05 2025

-

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >Aug 05 2025

-

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >Aug 05 2025

-

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >Aug 05 2025

-

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >Aug 05 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com