Premium WPC Exterior Wall Cladding | Durable & Low-Maintenance

As modern WPC exterior wall cladding transforms public, commercial, and private architecture worldwide, its impact on durability, style, and sustainability is reshaping the building envelope sector. Whether applied as wpc wall panel outdoor, exterior wpc wall panel, or wpc wall panel exterior, the material's resilience and aesthetics are increasingly preferred across industries. This comprehensive guide explores global market trends, technical parameters, manufacturing process, comparative data, real-world application, and tailored project solutions to assist architects, engineers, and developers in making informed decisions.

Industry Trends and Overview (2024)

According to the latest Wood Plastic Composite (WPC) Market Report, the global demand for wpc exterior wall cladding is projected to reach USD 10.6 billion by 2028, growing at a CAGR of 8.2% (2023-2028). Key drivers include heightened focus on energy-efficient and low-maintenance building exteriors, government green building mandates, and the rapid expansion of urban infrastructure in APAC and EMEA.

- 🌎 Market Growth (2023-2028): CAGR 8.2% ↑

- 🏗️ Main Applications: Residential High-rise, Commercial Buildings, Industrial Envelopes, Public Infrastructure

- 🔎 Certifications: ISO 9001, EN 15534, ASTM D7031

- 🌱 Sustainability: Up to 90% recycled content

What is WPC Exterior Wall Cladding?

WPC (Wood-Plastic Composite) exterior wall cladding is an advanced composite building material crafted by combining wood fibers or wood flour with thermoplastic polymers (HDPE, PVC) and performance additives. This fusion yields a robust, weatherproof, and visually striking alternative to traditional cladding materials such as timber, steel, fibre cement and metal. WPC cladding is engineered for wpc outdoor wall cladding applications—offering notable advantages in moisture resistance, UV stability, fade resistance, impact absorption, and insulation.

Manufacturing Process: WPC Exterior Wall Cladding

Raw Material

Wood Flour

& HDPE Resin

Mixing & Compounding

Additives, Coupling Agents

Extrusion or Molding

Profile Forming

Surface Finishing

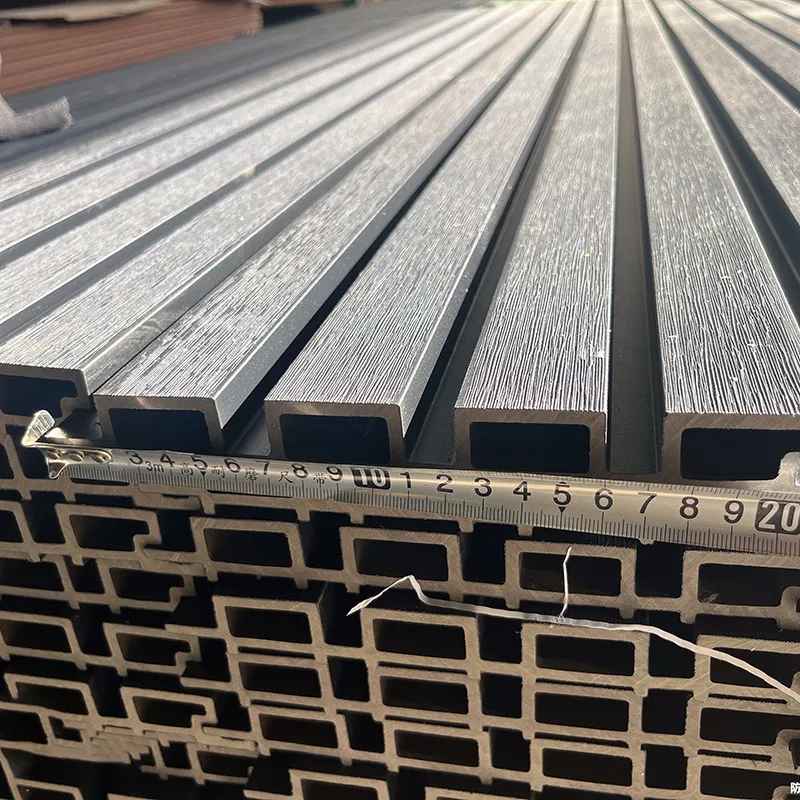

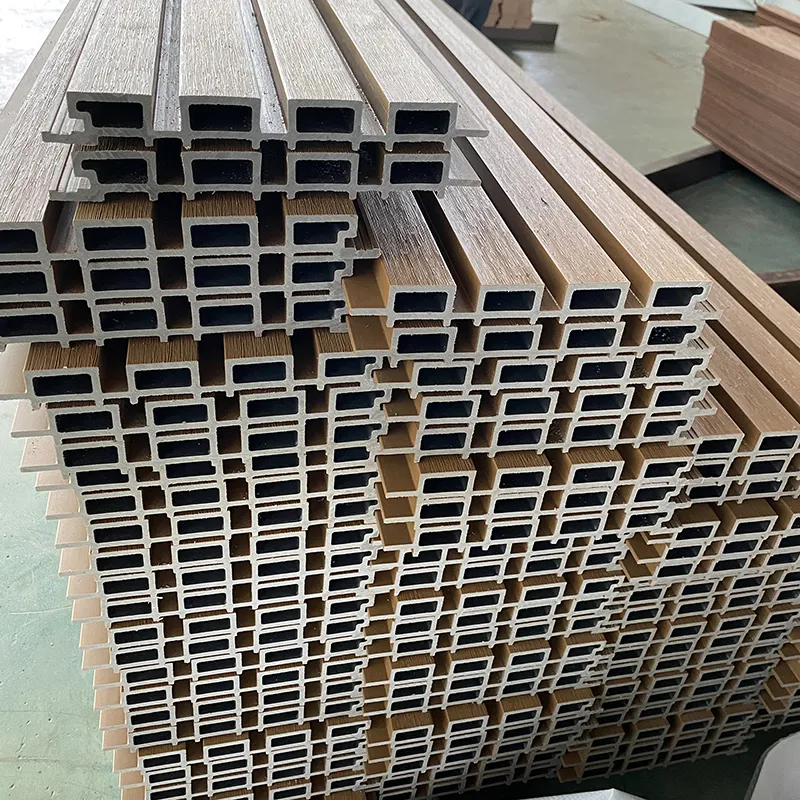

Brushing, Embossing

Quality Inspection

ISO, EN, ASTM

Packaging/Shipping

- Material Source: Up to 65% recycled wood, 25-35% HDPE, 2-5% performance additives (anti-UV, color, foaming agents, coupling agents)

- Process Highlights: Consistent mixing ensures even dispersion. Advanced extrusion/CNC cutting defines dimensional accuracy.

- Quality Testing: Full batch testing for ISO 9001, EN 15534, and ASTM D7032.

Technical Parameters & Key Performance Indices

| Specification | SOTHINK WPC Exterior Wall Cladding | Traditional Timber Cladding | PVC Cladding |

|---|---|---|---|

| Density (kg/m³) | 1260 | 800-950 | 1400 |

| Water Absorption (24h, %) | ≤0.40 | 6-9 | 0.80 |

| Thermal Expansion Coefficient (mm/m°C) | 0.045 | 0.022 | 0.070 |

| Flexural Strength (MPa) | 32 | 18-27 | 21 |

| UV Resistance (ΔE 500h) | <4.0 | >8.0 | 5.5 |

| Expected Lifespan (Years) | 30+ | 10-15 | 15-20 |

| Fire Standard | EN 13501-1:B-s2,d0 | D-s2, d2 | B-s3, d1 |

| Surface Finish | Custom Texture / Embossed / Matt | Natural Fibers | Smooth/Gloss |

UV Resistance Comparison (ΔE, 500h)

Market Share by Material (2023)

Water Absorption (24h) Trend

Comparative Advantages of WPC Exterior Wall Cladding

- Moisture-Proof & Anti-corrosive: Virtually zero water absorption and impervious to decay, ideal for humid and coastal climates.

- UV & Colorfast: wpc exterior wall cladding retains original color for 10+ years under ISO 4892-3/EN 15534.

- Superior Flexural & Impact Strength: Withstands external shocks (ASTM D790).

- Low Maintenance: No sanding, painting, or oiling required. Cleans with water jet only.

- Thermal Insulation: 35% higher R-value than PVC and metal panels.

- Green Building: LEED/BREEAM credits due to high recycled content, low VOC emissions, and ISO 14001 production compliance.

- Fire Safety: EN 13501-1 B-s2,d0 rating - slower flame spread.

Comparison of Leading WPC Cladding Manufacturers

| Brand | Main Product | Warranty | Main Certification | Export Markets | Custom Solutions |

|---|---|---|---|---|---|

| SOTHINK | WPC Exterior Wall Cladding | 30 Years | ISO 9001, EN 15534, SGS | Europe, NA, Asia, MEA | Yes (Color, Profile, Texture) |

| Fiberdeck (France) | WEO® 35/60 | 20 Years | EN 13501-1, PEFC | Europe, Africa | Partial |

| Eva-Last (South Africa) | Infinity® Cladding | 25 Years | ISO 14001, FSC® | Global | Yes |

| Trex (USA) | Cladding Series | 25 Years | ASTM D7031, ISO 9001 | USA, EU | No |

Custom Tailored Solutions: WPC Exterior Wall Cladding

Recognizing the unique needs of architects and contractors, SOTHINK offers complete customization on WPC exterior wall cladding profiles, colors, textures, and surface finishes:

- Design Options: Width 145-235 mm, thickness 20-30 mm, lengths up to 5.5 meters.

- Surface: Embossed woodgrain, brushed matt, color streaking.

- Color Matching: Over 25 proprietary and RAL-matched shades. Dual-tone extrusion available.

- Enhanced Fastening: Invisible clip, direct screw, and tongue & groove options for cladding.

- Profiles: Flat, batten, louver, slatted for modern exteriors.

- OEM/ODM: Support for project-specific profile extrusion and private label branding.

Application Scenarios & Case Studies

- Commercial High-rise: SOTHINK wpc exterior wall cladding secures 34,000 m² of facade at Qingdao CBD, offering 90% reduction in repainting costs over 20 years; meets ISO 5660 fire testing.

- School Buildings: 7,500 m² installed at Shenzhen International School for anti-mold, anti-graffiti, and low-toxicity requirements; confirms EN 71-3 children’s health standard.

- Industrial Settings: CNOOC chemical plants adopt SOTHINK WPC panels for corrosion resistance, withstands NaCl 600h salt spray (ASTM B117).

- Resort & Public Parks: Enhanced architectural appeal for Macau Waterfront project—fade resistance maintained <ΔE3.1 after 3 years exposure.

Client Voices: "Transitioning from painted aluminum to wpc exterior wall cladding halved our yearly maintenance; colors haven’t faded even after four typhoon seasons."—Li, Project Manager, HK School Authority (2023)

Industry Recognitions & Third-party Verifications

SOTHINK WPC wall solutions are certified to ISO 9001, EN 15534-2 and SGS chemical emission standards. Major collaborations include Poly Real Estate, Country Garden, and MCC Group. Panels are independently tested by TÜV Rheinland & SGS. All products are REACH, RoHS, and CE compliant.

- ISO 9001: Quality management for consistent profiles.

- EN 15534-2: Structural performance for façade use.

- SGS/REACH/CE: Low-VOC & environmental compliance.

FAQ: Technical Terms & Best Practices

Lead Time, Warranty & After-sales Support

- Production Lead Time: Standard profiles 15-18 days; custom R&D/OEM up to 28 days (FOB China port).

- Logistics: Palletized, international export crate; barcode and color lot tracking.

- Warranty: 30 years anti-fade and anti-rot warranty, transferable to next property owner.

- Technical Support: CAD layout, site engineering, responsive after-sales WhatsApp/WeChat support.

Conclusion & References

- Advantages of WPC Composite Cladding – Architecture & Design Forum, 2023

- Durability of Wood/Plastic Composites: A Review, Waste Management 2022 (Elsevier)

- WPC Wall Panels – Exterior WPC Panel Review – Woodworking Forum

- Thermal Properties of WPC Facade Applications; Building Research & Information Journal, 2021

-

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >Aug 05 2025

-

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >Aug 05 2025

-

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >Aug 05 2025

-

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >Aug 05 2025

-

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >Aug 05 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com