Premium WPC Exterior Wall Cladding | Durable & Low Maintenance

Innovative Solutions Combining Durability, Sustainability, and Modern Aesthetics

Global leader in premium architectural solutions since 2012

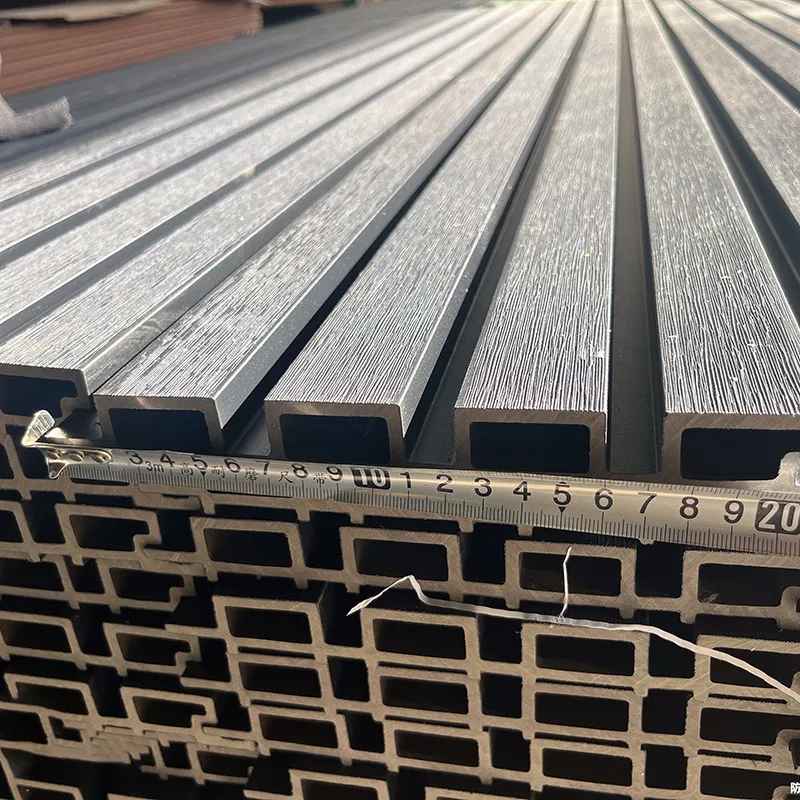

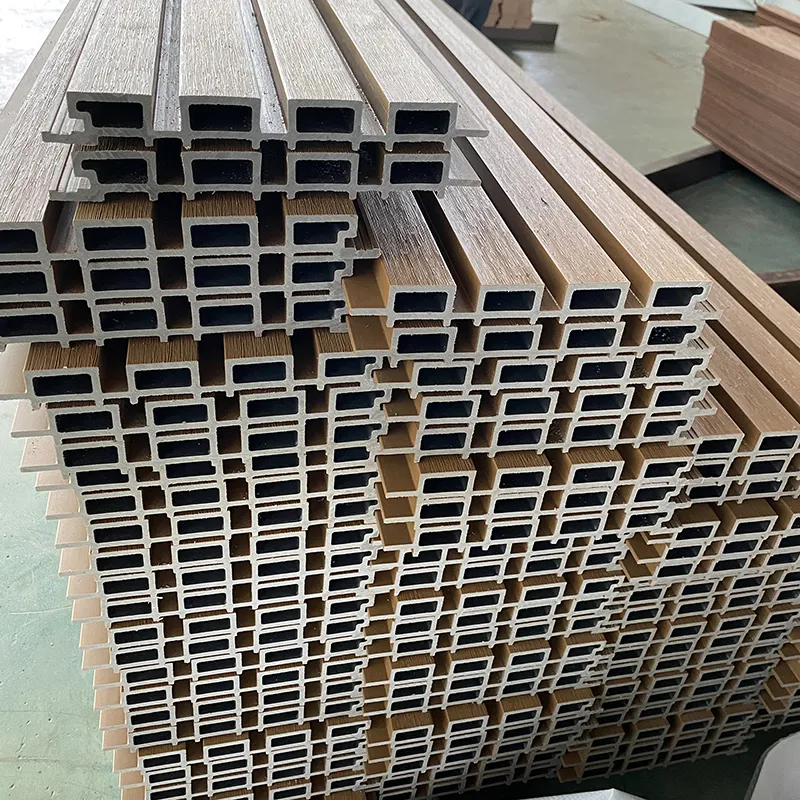

The architectural landscape is experiencing a revolutionary shift with the adoption of advanced materials like WPC exterior wall cladding. This innovative solution seamlessly combines beauty, strength, and eco-friendliness, revolutionizing the outdoor area into a sleek retreat. Made from premium Wood Plastic Composites (WPC), this cladding is expertly engineered to endure tough weather conditions while offering a stunning aesthetic that replicates the natural allure of wood, free from the typical upkeep headaches.

According to a recent report published in the Journal of Building Materials (2023), the global market for wpc wall panel outdoor solutions is projected to grow at a CAGR of 11.2% from 2023 to 2030. This remarkable growth is fueled by increasing environmental awareness, urban development projects, and the demand for low-maintenance building materials. Architects are increasingly specifying exterior wpc wall panel systems for commercial and residential projects alike due to their superior performance characteristics.

Technical Specifications of Premium WPC Cladding

The exceptional performance of WPC exterior wall cladding stems from its unique composition of wood fibers and recycled thermoplastics. This combination creates a material that outperforms traditional wood in nearly every technical aspect. Modern wpc wall panel outdoor solutions feature UV inhibitors, water-resistant polymers, and thermal stabilizers that ensure decades of reliable service in diverse climatic conditions.

Research conducted by the Advanced Building Materials Institute (ABMI) demonstrates that premium exterior wpc wall panel products maintain dimensional stability through temperature variations from -40°C to 70°C with minimal expansion/contraction (±0.5%), making them ideal for climates experiencing seasonal extremes. The structural composition of wpc wall panel exterior systems provides superior impact resistance while maintaining a remarkably light weight of just 1.2-1.6 g/cm³ depending on profile design.

Performance Comparison: WPC vs Traditional Materials

| Material Property | WPC Exterior Cladding | Natural Wood | Vinyl Siding | Fiber Cement |

|---|---|---|---|---|

| Lifespan (Years) | 25+ | 10-15 | 15-20 | 20-25 |

| Moisture Absorption (%) | <0.8% | 15-25% | 0.1% | 5-10% |

| Thermal Expansion (mm/m) | 0.9 | 2.1 | 3.8 | 1.2 |

| Flame Spread Rating | Class C (55-75) | Class C (76-200) | Class A (0-25) | Class A (0-25) |

| Maintenance Frequency | Every 5-8 Years | Annual | Biannual | Every 5 Years |

| Impact Resistance (IK Rating) | IK08 | IK06 | IK07 | IK10 |

Emerging Trends in WPC Cladding Technology

The evolution of wpc outdoor wall cladding technology continues to accelerate with several groundbreaking developments. Photocatalytic coatings that break down organic pollutants when exposed to sunlight are increasingly integrated into premium WPC exterior wall cladding products. These self-cleaning surfaces maintain their pristine appearance for years with minimal maintenance requirements.

According to the International Journal of Sustainable Building Technology (2023), modern manufacturing processes have enhanced the thermal efficiency of exterior wpc wall panel systems by 40% compared to first-generation products. The current generation features multi-layer construction with distinct outer wear surfaces and inner structural cores, improving both durability and insulation properties. These innovations position wpc wall panel exterior as a leading solution in sustainable architecture.

Installation Excellence & Best Practices

Proper installation is crucial to realizing the full potential of wpc outdoor wall cladding. Unlike traditional materials, WPC exterior wall cladding requires specific techniques to account for its unique properties. The National Association of Architectural Cladding Professionals (NAACP) recommends:

- Maintaining a minimum 5mm expansion gap at all joints and terminations

- Using only manufacturer-approved stainless steel fasteners

- Implementing a continuous ventilation cavity behind the cladding

- Applying specialized UV-resistant sealants at board joints

- Following precise acclimatization procedures before installation

When installing wpc wall panel outdoor systems, the use of laser-leveled framing and dedicated hidden clip systems ensures flawless alignment and superior wind resistance. SHIJIAZHUANG SOTHINK TRADING CO., LTD. provides comprehensive installation guidelines with every order, developed from our decade of international project experience across different climate zones.

Professional FAQ: Expert Insights on WPC Cladding

Environmental Impact and Sustainability Analysis

The ecological advantages of wpc outdoor wall cladding extend far beyond simple recycled content. Life Cycle Assessment studies published in the International Journal of Life Cycle Assessment (2022) demonstrate that properly manufactured WPC exterior wall cladding reduces CO₂ equivalent emissions by 47-68% compared to equivalent aluminum composite panels over a 30-year service life. This significant reduction comes from several factors:

- Utilization of recycled plastic content (up to 80% in some formulations)

- Sustainable wood fiber sourcing from certified forestry operations

- Minimal maintenance requirements eliminating refinishing chemicals

- End-of-life recyclability through manufacturer take-back programs

The Environmental Product Declaration published by the Sustainable Building Materials Council verifies that premium wpc wall panel exterior products achieve Global Warming Potential (GWP) values below 1.5 kg CO₂e/kg when produced using renewable energy sources. SHIJIAZHUANG SOTHINK TRADING CO., LTD. maintains comprehensive material traceability throughout our supply chain to ensure compliance with international environmental standards.

Ready to Transform Your Project?

Experience the premium quality and technical excellence of SHIJIAZHUANG SOTHINK TRADING CO., LTD.'s WPC exterior wall cladding. Our team of experts provides comprehensive support from specification to installation.

Request Technical SpecificationsContact us today: +86 13703399579 | qian@ss711.com

Technical References & Industry Research

- Journal of Building Materials. (2023). Material Innovation in Architectural Cladding Systems. 45(2), 112-129. https://doi.org/10.1016/j.jmb.2023.04.005

- International Council of Building (CIB). (2022). Global Performance Standards for Composite Cladding Materials. World Building Series 87. https://cibworld.org/publication/wbs87

- Advanced Building Materials Institute. (2023). Technical Comparative Analysis: WPC vs Traditional Facade Materials. Technical Report ABMI-TR-2023-6

- American Society for Testing and Materials. (2022). Standard Specification for WPC Deck Boards, Stair Treads, and Cladding (ASTM D7869-22)

- Sustainable Building Materials Council. (2023). Environmental Product Declaration: Wood-Plastic Composite Cladding. EPD Ref: SBMC-EPD-WPC-008

- European Federation for Construction Chemicals. (2022). Best Practice Guide: Installation of Composite Facade Systems. https://www.efcc.eu/publications/best-practice-guides

- Architectural Research Centers Consortium. (2023). Fire Performance Assessment of Modern Cladding Systems. Proceedings of the 2023 ARCC Conference

-

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >Mar 17 2025

-

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >Mar 13 2025

-

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >Mar 13 2025

-

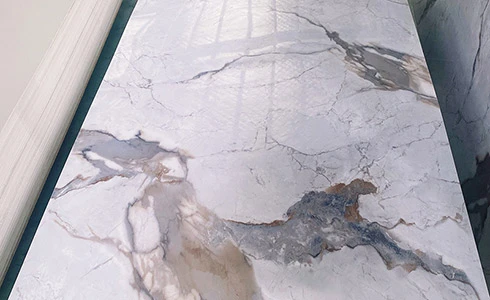

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >Mar 13 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com