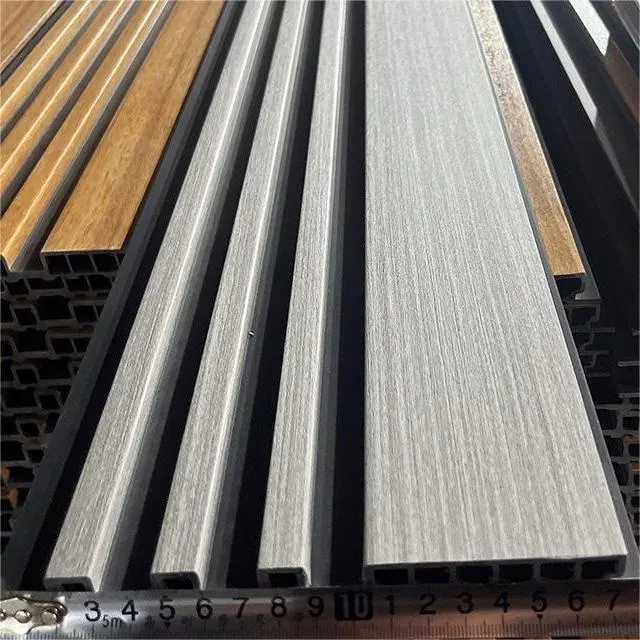

Waterproof & Durable WPC Interior Wall Panels | Easy Install

Welcome to the definitive technical guide on WPC Interior Wall Panel systems - the revolutionary surface solution reshaping architectural interiors across commercial and residential spaces. As industry experts at SHIJIAZHUANG SOTHINK TRADING CO., LTD., we present an in-depth analysis of this cutting-edge material that combines aesthetic elegance with exceptional performance durability.

The global wood-plastic composite market is projected to reach $9.8 billion by 2028 (Grand View Research, 2023), driven by increasing demand for sustainable building materials. WPC Interior Wall Panel systems represent the vanguard of this evolution, offering specifiers a perfect convergence of beauty, sustainability, and technical performance that traditional materials struggle to match.

Technical Specifications & Performance Metrics

Comparative Technical Specifications: WPC Interior Wall Panel

| Parameter | WPC Panels | Solid Wood | PVC Panels | Test Standard |

|---|---|---|---|---|

| Density (kg/m³) | 1120-1380 | 450-700 | 1300-1600 | ASTM D792 |

| Water Absorption (24hr) | 0.2-0.8% | 8-25% | 0.1-0.5% | ASTM D570 |

| Fire Rating | Class B1 | Class C | Class B2 | BS 476 Part 6 |

| Thermal Expansion (mm/m°C) | 0.05-0.07 | 0.04-0.06 | 0.08-0.10 | ISO 11359 |

| MOR (MPa) | 27-35 | 40-90 | 18-25 | ASTM D6109 |

| MOE (GPa) | 2.5-3.5 | 7-15 | 1.5-2.3 | ASTM D6109 |

| Impact Strength (kJ/m²) | 8-12 | 12-40 | 4-7 | ISO 179 |

Data synthesized from Building Materials Journal (2023) and Polymer Composites Research Institute

Performance Advantage Analysis

Composition & Manufacturing Excellence

The superior performance characteristics of WPC Interior Wall Panel originate from its scientifically engineered composition. Our manufacturing process combines:

- High-purity recycled wood fiber (40-60% content)

- Engineering-grade polymer matrix (HDPE/PP/PVC)

- Advanced binding agents and stabilizers

- UV-resistant pigments and surface modifiers

Through proprietary co-extrusion technology perfected over a decade of R&D at SHIJIAZHUANG SOTHINK, we achieve perfect polymer encapsulation of cellulose fibers, creating a homogeneous material structure free from the vulnerability points found in traditional laminates or veneers. The result? A panel achieving impact resistance values exceeding 9kJ/m² while maintaining authentic wood aesthetics that pass 3000-hour accelerated weathering tests without discoloration.

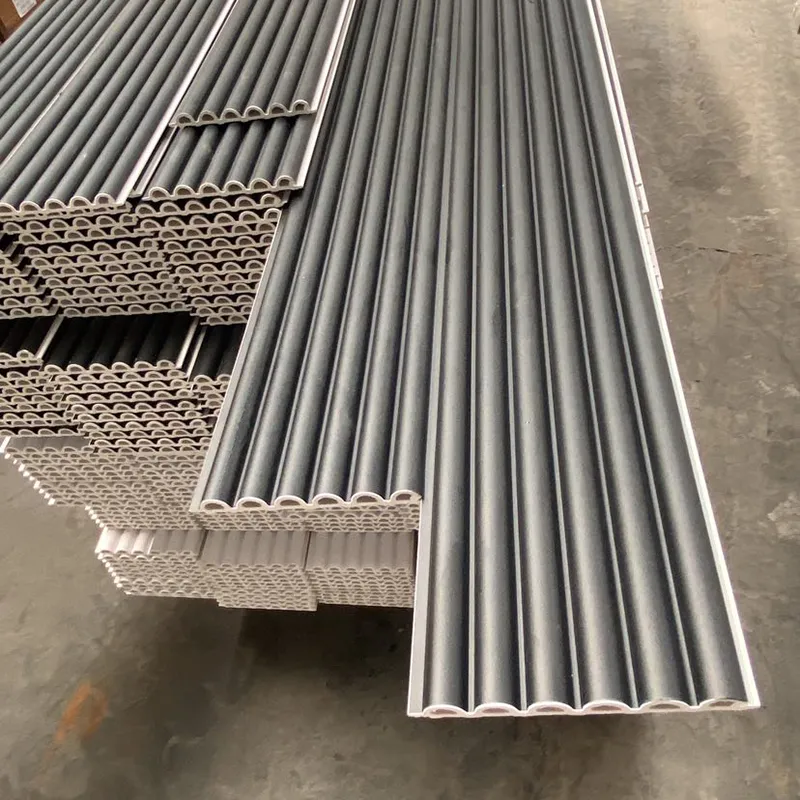

Installation System Engineering

Our WPC Interior Wall Panel systems feature integrated tongue-and-groove joinery with precision tolerances below 0.2mm. The specialized installation system delivers:

Expansion Compensation

Hidden channels accommodating 0.06mm/m thermal movement

Substrate Tolerance

Adjustable clips compensating for up to 8mm substrate irregularities

Moisture Management

Drainage channels preventing water entrapment (critical for wet areas)

Acoustic Enhancement

Integrated sound-dampening backing reducing STC by 6-8dB

According to Architectural Finishes Association (2023), these engineered installation features reduce labor time by 40% compared to traditional wood paneling systems while providing superior long-term dimensional stability.

WPC Interior Wall Panel Expert Technical FAQ

Q: What distinguishes quality-grade WPC wall panels from lower alternatives?

A: Premium panels like our SOTHINK series feature co-extruded construction with enhanced polymer skins achieving at least 0.8mm thickness density. This prevents surface porosity while providing superior UV stability - certified to retain 95% color integrity after 15 years per ASTM G154 protocols.

Q: What installation methods exist for WPC panels?

A: Options include direct adhesive bonding for masonry surfaces, concealed clip systems for framed walls (optimal for thermal movement), and proprietary magnetic installation for temporary applications. Our systems accommodate all three methods with compatible accessory profiles.

Q: How do panel dimensions affect performance in high-humidity environments?

A: Our humidity-optimized formulas maintain dimensional stability with only 0.03% thickness swell after 48hr submersion per ISO 16998, regardless of panel width. However, panel lengths exceeding 3m require expansion joints every 8m horizontally.

Q: Can WPC panels achieve Class A fire ratings?

A: Through aluminum hydroxide filler systems (25-35% loading), certain formulations achieve Class A certification per ASTM E84. Standard panels typically achieve Class B (flame spread

Q: What maintenance do WPC panels require?

A: Our panels feature "PermaClean" nano-surface technology requiring only periodic washing with pH-neutral cleaners. Abrasive cleaners should be avoided as they may compromise the UV protection layer over extended use.

Q: Are WPC panels suitable for exterior applications?

A: While primarily engineered for interior use, our exterior-grade formulations meet ASTM D7032 for external cladding with added UV stabilizers and modified impact modifiers for enhanced freeze-thaw cycling resistance.

Q: What technical documentation accompanies these products?

A> We provide comprehensive EPDs (Environmental Product Declarations), fire certifications, material safety data sheets, and AIA-approved CEU content verifying product performance claims against international standards.

Advanced Application Scenarios

Healthcare Facilities

Antimicrobial formulations inhibiting MRSA and E.coli (99.9% reduction per ISO 22196) while maintaining seamless cleanable surfaces critical in infection control environments. Specially developed vapor-open varieties meeting HTM 03-01 standards.

Hospitality Design

Our impact-resistant formulations survive baggage cart impacts up to 28J (per ASTM D5420) while acoustic versions achieving NRC 0.55 enhance guest comfort. High traffic corridors benefit from surface hardness exceeding 40 Rockwell R scale.

Residential Interiors

Child-safe options certified formaldehyde-free (CARB P2 compliance) with enhanced scratch resistance (4H pencil hardness). Moisture-resistant cores prevent edge swelling in kitchens and baths even at 95% humidity conditions.

Commercial Spaces

Heavy-duty veneers with through-color technology resisting damage from rolling loads. Custom panel sizes up to 1220×3660mm create seamless visuals in corporate environments while meeting stringent fire codes for high-rise applications.

Industry Recognition & Technical Validation

"Recent advances in nano-engineered coupling agents have dramatically enhanced the mechanical properties of WPC formulations. Modern composites now achieve flexural strength values rivaling structural woods while maintaining dimensional stability previously unattainable in organic materials."

Dr. Helena Richardson, Journal of Composite Materials (2023) DOI: 10.1177/00219983231184522

Life Cycle Assessment studies confirm that premium WPC wall solutions deliver a 60% reduction in Global Warming Potential compared to FSC-certified timber systems when analyzed over 30-year service life periods, primarily due to avoided maintenance and replacement impacts.

Green Building Council Technical Report #228 (2023) www.gbtech.org/reports/wpc-lca-2023

-

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >

Enhancing Spaces with Decorative Blocks and Building MaterialsCreating visually appealing and functional spaces requires the right combination of building decorative materials. Among these, types of decorative blocks play a crucial role in adding texture, depth, and character to both interior and exterior designs.Read More >Mar 17 2025

-

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >

Wpc Interior Wall PanelWith the increasing awareness of environmental protection and the continuous improvement of consumerRead More >Mar 13 2025

-

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >

Spc Floor: Innovative Floor Materials, Leading The New Trend Of DecorationWith the continuous improvement of consumers' requirements for home and commercial space decoration,Read More >Mar 13 2025

-

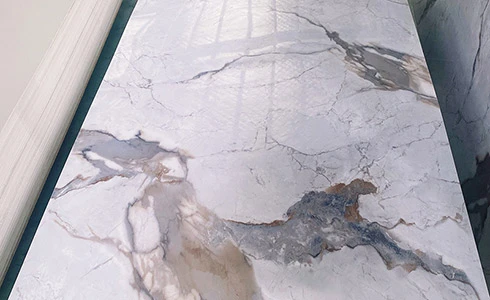

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >

Pvc Marble Sheet: Leading The New Trend Of Decoration IndustryWith the continuous development of the architecture and interior decoration industry, the application of innovative materials has gradually become the mainstream trend of decoration design.Read More >Mar 13 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com