Premium WPC Fence Panels for Sale - Durable, Low-Maintenance

Navigating the Market: Industry Trends in WPC Panels

The global demand for sustainable and high-performance building materials has driven significant innovation in the WPC (Wood Plastic Composite) sector. Specifically, the market for wpc fence panels for sale is experiencing robust growth, fueled by their superior durability, minimal maintenance requirements, and aesthetic versatility. Modern construction projects, both commercial and residential, increasingly prioritize materials that offer an optimal balance of environmental responsibility and long-term cost-effectiveness. The rising consciousness regarding eco-friendly alternatives to traditional wood and plastic products has positioned WPC as a leading choice for various applications, from exterior fencing to interior wall cladding. This growth is further amplified by advancements in manufacturing processes, which allow for a broader range of designs, textures, and color options, meeting the diverse architectural and design specifications of a global clientele. Furthermore, the inherent resistance of WPC to rot, decay, insects, and moisture makes it particularly attractive for outdoor applications, ensuring longevity in diverse climatic conditions, which is a critical factor for B2B procurement in construction and landscaping industries. The drive for reduced carbon footprints and circular economy principles is consistently propelling WPC materials into the forefront of sustainable development strategies, offering a tangible solution for environmentally conscious building practices.

Key industry trends indicate a strong shift towards specialized WPC products, including those catering to specific aesthetic demands, such as wpc wall panel wholesalers seeking unique designs and simplified installation systems. There's a noticeable increase in the adoption of co-extruded WPC panels, which offer enhanced scratch resistance and UV stability, thereby extending the product's lifespan and reducing lifecycle costs. The market is also seeing a diversification of applications beyond traditional decking and fencing, with significant expansion into interior design as an elegant and robust wpc wallpanel solution. This evolution is supported by continuous research and development efforts focused on improving material composition, dimensional stability, and fire resistance, aligning WPC products with stringent international building codes and performance standards. For B2B stakeholders, understanding these trends is crucial for strategic sourcing and product development, ensuring that material choices reflect both current market demands and future sustainability objectives. The ability of WPC panels to mimic the appearance of natural wood without the associated maintenance issues positions them as an economically viable and aesthetically pleasing alternative for both renovation and new construction projects, signifying a major shift in material specification across the global construction supply chain.

Precision Engineering: The Manufacturing Process of WPC Panels

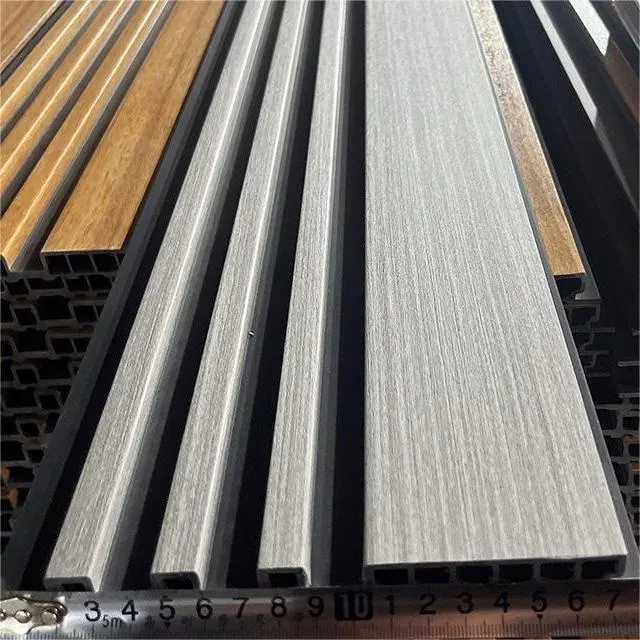

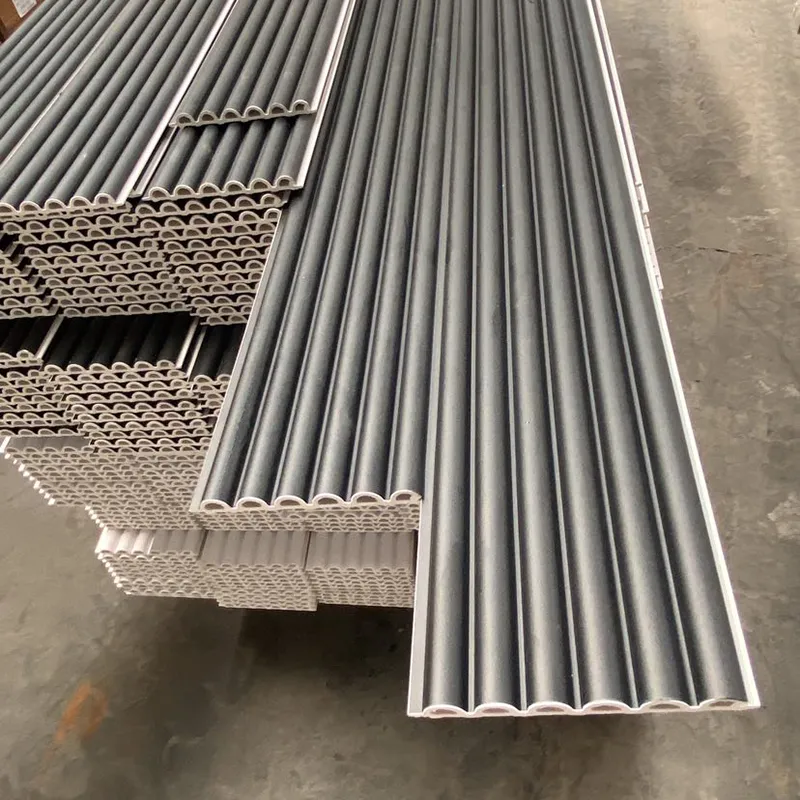

The production of high-quality wpc fence panels for sale involves a sophisticated, multi-stage manufacturing process that ensures consistent material properties and superior performance. Unlike traditional materials that may involve casting or forging, WPC panels are primarily manufactured through extrusion or compression molding, leveraging the inherent characteristics of composite materials. The process begins with the careful selection and precise blending of raw materials, typically comprising fine wood fibers (or other cellulose-based materials like bamboo or rice husks), recycled plastics (such as HDPE, PVC, or PP), and a proprietary mix of chemical additives including coupling agents, UV stabilizers, pigments, and lubricants. This blend is then heated and homogenized in a high-intensity mixer, ensuring a uniform distribution of all components. The critical phase is the extrusion, where the molten composite is forced through a die to form the desired profile, such as a hollow or solid panel, or even a tongue-and-groove wpc wall panel. Advanced extrusion lines employ precise temperature control and pressure regulation to achieve optimal density and dimensional stability, which are crucial for the structural integrity and aesthetic consistency of the final product.

Post-extrusion, the panels undergo a cooling process, often in water baths, to solidify their form and minimize warping. This is followed by sizing and cutting to precise lengths. Many premium wall panel wpc products then proceed to a surface treatment stage, which may include sanding for a wood-like finish, brushing to enhance texture, or applying a co-extruded cap layer for superior protection against scratches, stains, and UV degradation. This co-extrusion technology significantly enhances the panel's lifespan and reduces maintenance needs. Quality control is integrated throughout the entire manufacturing flow. Panels are rigorously inspected against stringent internal and international standards such as ISO 9001 for quality management and ISO 14001 for environmental management. Performance tests include impact resistance, flexural strength, water absorption rates, and accelerated weathering tests (e.g., ASTM G154 for UV exposure) to ensure longevity and suitability for diverse climates. This meticulous process guarantees that the end product, whether for fencing or interior decor, delivers consistent performance and adheres to the highest industry benchmarks, ensuring reliability and customer trust.

Unpacking Performance: Technical Specifications and Metrics

For B2B procurement, a detailed understanding of the technical specifications of wpc fence panels for sale is paramount for making informed decisions that align with project requirements and long-term investment goals. WPC panels are engineered to offer a superior alternative to traditional materials, providing an array of performance benefits. Key parameters include density, typically ranging from 0.8 g/cm³ to 1.4 g/cm³ depending on the wood fiber and plastic composition, which directly influences the panel's strength and weight. Flexural strength, measured in MPa, indicates the material's resistance to bending or deformation under load, with typical values for quality WPC panels often exceeding 30 MPa. Water absorption, a critical factor for outdoor applications, is typically less than 1% after 24 hours immersion, signifying excellent resistance to moisture-induced swelling or warping, unlike natural wood. Furthermore, UV resistance is quantified by performance in accelerated weathering tests (e.g., color fade index after specific hours of QUV exposure), where advanced formulations show minimal color change, ensuring aesthetic longevity.

Beyond these mechanical properties, WPC panels excel in their resistance to biological degradation, being impervious to termites, fungi, and rot, which contributes significantly to their extended service life, often projected for 15-25 years depending on environmental conditions and maintenance. Thermal expansion coefficients are also important for installation, as WPC expands and contracts less than pure plastic, maintaining dimensional stability. Fire resistance, measured by standards such as ASTM E84 (Surface Burning Characteristics), often classifies WPC with a Class B or C rating, indicating moderate flame spread and smoke development, superior to many natural wood products. The following table provides a comprehensive overview of typical parameters for high-grade WPC Interior Wall Panels, aiding in direct comparison and specification for diverse project needs, whether for an intricate wpc wall panel installation or a robust fencing system. These empirical data points underscore the material's suitability for demanding environments and its cost-efficiency over time due to reduced replacement and maintenance cycles.

| Parameter | Unit | Typical Value (High-Grade WPC) | Testing Standard |

|---|---|---|---|

| Density | g/cm³ | 0.9 - 1.3 | ASTM D792 |

| Flexural Strength | MPa | > 25 | ASTM D790 |

| Water Absorption (24h) | % | < 0.5 | ASTM D570 |

| Impact Strength (Izod) | J/m | > 600 | ASTM D256 |

| Hardness (Shore D) | - | > 65 | ASTM D2240 |

| UV Resistance (Color Fade) | ΔE | < 3 (after 2000h QUV) | ASTM G154 |

| Fire Rating | Class | B or C | ASTM E84 |

| Operating Temperature Range | °C | -30 to +60 | Manufacturer's Data |

Versatile Applications: Scenarios and Advantages

The versatility of wpc fence panels for sale makes them ideal for a broad spectrum of applications, extending well beyond traditional residential fencing. In commercial and public sectors, WPC panels are increasingly specified for their low-maintenance profile and robust performance in high-traffic areas. For instance, in landscaping and urban planning, WPC fencing is utilized for perimeter security, decorative partitions, and privacy screens in parks, public squares, and commercial complexes. Their resistance to environmental degradation, including moisture, UV radiation, and temperature fluctuations, ensures that they maintain their structural integrity and aesthetic appeal for decades, significantly reducing the lifecycle costs associated with painting, staining, or replacing traditional wood fences. Furthermore, WPC's splinter-free surface and non-toxic composition make it a safe choice for public spaces, including playgrounds and schools. The inherent anti-corrosion properties of WPC, attributed to its plastic component, render it highly suitable for installations near coastal areas or in environments exposed to chemical agents, where metal or natural wood would quickly deteriorate.

Beyond exterior applications, the demand for high-quality wpc wall panel solutions for interiors is rapidly expanding. In hospitality, retail, and office environments, WPC interior panels offer a sophisticated and durable wall cladding option that mimics the warmth of natural wood or stone textures without the associated vulnerabilities. These panels contribute to superior indoor air quality as they are typically free from formaldehyde and other volatile organic compounds (VOCs). Their thermal insulation properties can also contribute to marginal energy savings by improving the building envelope's efficiency, a critical advantage for commercial energy management. Acoustically, certain WPC panel designs can contribute to sound dampening, enhancing the comfort of interior spaces. Furthermore, the ease of installation, often leveraging tongue-and-groove systems, significantly reduces labor costs and project timelines for large-scale developments, making them a preferred choice for `wpc wall panel wholesalers` and large-scale builders. The adaptability of WPC allows for custom solutions, from intricate decorative patterns to robust industrial partitions, providing architects and designers with unparalleled flexibility in material specification.

Strategic Sourcing: Manufacturer Comparison and Custom Solutions

Selecting the right supplier for wpc fence panels for sale is a critical decision for any B2B entity, impacting product quality, project timelines, and overall cost-effectiveness. The market is populated by various manufacturers, each with unique strengths in material composition, manufacturing techniques, and service offerings. A thorough comparison often reveals key differentiators such as the ratio of wood fiber to plastic content, which influences rigidity and weight; the type of plastic polymer used (e.g., HDPE offers superior moisture resistance, while PVC provides better flame retardancy); and the incorporation of advanced additives for UV protection, mold resistance, or enhanced color stability. Leading manufacturers distinguish themselves not only through adherence to international standards like ISO 9001 and CE marking but also through transparent material sourcing practices and verifiable third-party test reports. Established companies often boast extensive production capacities, ensuring consistent supply for large-scale projects, and a proven track record, demonstrated by years of industry experience and successful project completions.

Furthermore, the ability to provide customized solutions is a significant competitive advantage for manufacturers of wpc wall panel products. Customization extends beyond mere color and texture variations to include bespoke dimensions, unique profiles for specific architectural integration, and specialized surface finishes. For example, a project requiring a specific panel thickness or a custom interlocking system for rapid installation would benefit immensely from a manufacturer capable of delivering such tailored products. Manufacturers like Sothink Decor, with their long-standing presence since 2008 and expertise in WPC products, typically offer comprehensive support, from initial design consultation and material sampling to logistics and after-sales service. Their robust R&D capabilities enable the development of new product lines that anticipate market demands, such as innovative co-extruded WPC panels or fire-rated `wall panel wpc` systems, catering to evolving regulatory requirements and design trends. Engagements with such experienced partners ensure that B2B clients receive not just a product, but a complete solution backed by technical expertise and reliable support, enhancing the overall value proposition.

| Feature/Criterion | Leading Manufacturer (e.g., Sothink Decor) | Standard Manufacturer |

|---|---|---|

| Years in Business | > 15 years (e.g., since 2008) | < 10 years |

| Certifications | ISO 9001, CE, FSC, ASTM Compliance | Basic CE or none |

| Product Range | Extensive (fencing, decking, wall panels, custom profiles) | Limited (e.g., only decking) |

| Customization Capability | High (size, color, profile, finish, bespoke solutions) | Low (limited colors/sizes) |

| R&D Investment | High (new technologies, material innovation) | Low to none |

| Warranty Period | 10-25 years (material specific) | 5-10 years or conditional |

| Technical Support | Comprehensive (design, installation, after-sales) | Basic or reactive |

Real-World Impact: Application Case Studies and Client Trust

The proven track record of WPC panels in diverse global projects underscores their reliability and performance, reinforcing confidence for prospective B2B clients seeking wpc fence panels for sale. Consider a large-scale residential development in a subtropical climate where conventional wood fences frequently succumbed to humidity and insect infestations. The transition to WPC fencing provided a sustainable, low-maintenance solution that withstood extreme weather, maintaining its structural integrity and aesthetic appeal without requiring annual treatments. Customer feedback from this project highlighted significant cost savings in labor and materials for ongoing maintenance, alongside enhanced property value due to the panels' lasting visual quality. Another compelling case involves a commercial leisure complex integrating wpc wall panel systems in its interior and exterior common areas. The ability of WPC to mimic high-end wood finishes while offering superior resistance to wear, tear, and moisture made it an ideal choice for high-traffic environments, significantly reducing the facility's operational overhead for upkeep and refurbishment.

Furthermore, a notable collaboration with a leading hotel chain for their new eco-resort involved the extensive use of WPC for both decorative and functional elements, including exterior facades, poolside decking, and interior `wpc wallpanel` accents. The project demanded materials that were not only aesthetically pleasing but also environmentally responsible and highly durable against constant exposure to chlorine, salt air, and high foot traffic. The chosen WPC solutions met all these criteria, delivering an elegant, natural look that complemented the resort's sustainable design philosophy while requiring minimal intervention over its lifespan. These successful applications serve as powerful testimonials to the practical benefits and long-term value offered by WPC products. Client support, from initial consultation to post-installation, often includes detailed installation guides, technical assistance, and a clear warranty framework, fostering a high level of trustworthiness and ensuring client satisfaction throughout the project lifecycle. These real-world examples solidify WPC's position as a reliable, high-performance material for demanding architectural and construction projects.

Ensuring Confidence: FAQs, Delivery, and Warranty

Building trust with B2B clients requires transparent communication, clear commitments, and robust support systems. When considering wpc fence panels for sale, common questions often arise regarding durability, maintenance, and installation. Our comprehensive FAQ section addresses these concerns directly, providing precise and expert answers. For example, a frequently asked question might be: "What is the expected lifespan of WPC fence panels?" The answer would detail the typical 15-25 year lifespan, contingent on proper installation and environmental factors, supported by accelerated weathering test data. Another common inquiry: "Do WPC panels require special maintenance?" The response would highlight their low-maintenance nature, requiring only occasional cleaning with soap and water, eliminating the need for painting, staining, or sealing, thereby reducing long-term operational costs significantly for commercial clients or wpc wall panel wholesalers. These direct answers, backed by empirical data and industry standards, foster confidence.

- Q: What is the lead time for large orders of WPC panels?

- A: Standard lead times for WPC Interior Wall Panel orders typically range from 2 to 4 weeks, depending on order volume and customization requirements. Expedited options are available upon request for urgent projects, subject to production schedule review. We prioritize efficient logistics to meet project deadlines.

- Q: How does the warranty apply to WPC products?

- A: Our WPC panels come with a comprehensive limited warranty, typically ranging from 10 to 25 years, covering manufacturing defects, severe fading, and structural integrity under normal use. Specific terms and conditions are provided with each quotation, ensuring full transparency.

- Q: Can WPC panels be used in extreme temperatures?

- A: Yes, high-quality WPC panels are engineered to perform reliably across a wide temperature range, typically from -30°C to +60°C, exhibiting minimal expansion or contraction. This resilience makes them suitable for diverse global climates, from harsh winters to intense summers, without compromising structural integrity or appearance.

Regarding delivery and logistics, our commitment to reliability is paramount. We provide detailed delivery schedules, manage freight forwarding, and ensure secure packaging to prevent transit damage for large volume orders of wpc wallpanel products. Our logistics team collaborates closely with clients to coordinate delivery precisely with project timelines, minimizing on-site storage needs and streamlining installation. Customer support extends beyond mere product delivery; it encompasses technical assistance for installation, guidance on maintenance, and prompt resolution of any post-purchase inquiries. This end-to-end support model, coupled with a robust warranty, forms the cornerstone of our promise of trust and long-term partnership with our B2B clientele, ensuring that investment in our WPC solutions translates into sustained value and operational efficiency.

References

- American Society for Testing and Materials (ASTM) Standards for Wood-Plastic Composites.

- International Organization for Standardization (ISO) 9001:2015 - Quality Management Systems - Requirements.

- International Organization for Standardization (ISO) 14001:2015 - Environmental Management Systems - Requirements with guidance for use.

- Forest Stewardship Council (FSC) Certification Standards for Responsible Forest Management.

- Building Codes and Regulations pertaining to composite materials in construction (e.g., IBC, Eurocodes).

-

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >Aug 05 2025

-

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >Aug 05 2025

-

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >Aug 05 2025

-

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >Aug 05 2025

-

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >Aug 05 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com