Premium WPC Fence Panels for Sale | Durable & Eco-Friendly

Embracing Innovation: The Evolution of WPC Fence Panels for Modern Architecture and Design

The global demand for sustainable, durable, and aesthetically versatile building materials has driven significant advancements in composite technologies, with Wood Plastic Composite (WPC) emerging as a frontrunner. Specifically, the market for wpc fence panels for sale has witnessed exponential growth, transforming both residential and commercial landscaping as well as interior design applications. This surge is primarily fueled by WPC's inherent advantages over traditional materials like natural wood or conventional plastics. Unlike wood, WPC offers unparalleled resistance to rot, decay, insect infestation, and moisture absorption, significantly reducing maintenance requirements and extending service life. When compared to pure plastics, WPC provides a more natural, tactile feel and superior structural integrity, mimicking the warmth of wood without its vulnerabilities. Industry trends indicate a strong shift towards eco-friendly building solutions, where WPC, often manufactured from recycled plastics and wood fibers, aligns perfectly with global sustainability initiatives. This alignment makes it a preferred choice for architects, contractors, and developers aiming to achieve green building certifications and reduce environmental footprints. The versatility of wpc wall panel wholesalers has also expanded, offering a diverse range of textures, colors, and profiles that cater to sophisticated design specifications, from rustic charm to sleek modern aesthetics. Furthermore, technological advancements in WPC compounding and extrusion processes have led to enhanced material properties, including improved UV resistance and color stability, ensuring that installations maintain their appeal over decades. The rising adoption rates in regions prioritizing resilient and low-maintenance infrastructure further underscore the market's trajectory. This comprehensive evolution positions WPC panels as a pivotal material in contemporary construction, promising long-term value and sustainable performance across a multitude of applications. The ability to seamlessly integrate with diverse architectural styles, coupled with their robust performance under varying climatic conditions, solidifies the position of WPC as a cornerstone of modern, sustainable design.

The demand for innovative material solutions extends beyond mere durability; it encompasses complex environmental considerations and aesthetic flexibility. The market for wpc wallpanel solutions is dynamically responding to these needs, offering products that are not only high-performing but also visually adaptable. A key industry trend is the increasing customization of WPC panels to meet bespoke project requirements. This includes specialized finishes, non-standard dimensions, and unique interlocking systems, moving beyond generic stock options. The drive for greater aesthetic appeal has led to the development of advanced surface treatments, such as 3D wood grain embossing, brushed finishes, and co-extruded caps that provide enhanced resistance to fading and scratches. These innovations significantly elevate the perceived value and design potential of WPC products, making them suitable for high-end applications in residential, commercial, and hospitality sectors. Furthermore, the integration of smart technologies, such as embedded lighting solutions or sound-absorbing properties, into WPC panels represents another frontier of innovation, expanding their functional utility. Supply chain optimization, particularly among wpc wall panel wholesalers, is also a critical trend, focusing on efficient logistics and reduced lead times to support large-scale projects. This ensures that the robust and reliable supply of high-quality WPC solutions can keep pace with accelerating construction demands. The shift towards circular economy principles is also influencing WPC manufacturing, with greater emphasis on post-consumer recycling and end-of-life product management, further cementing WPC's role as a sustainable material. The market is also seeing increased investment in research and development to improve WPC formulation, particularly in enhancing fire resistance and structural stability for more demanding applications. This continuous evolution in product design, manufacturing efficiency, and sustainability practices ensures WPC panels remain at the forefront of modern building material innovation, offering a compelling blend of performance, aesthetics, and environmental responsibility.

The Advanced Manufacturing Process of WPC Panels: From Raw Materials to Refined Solutions

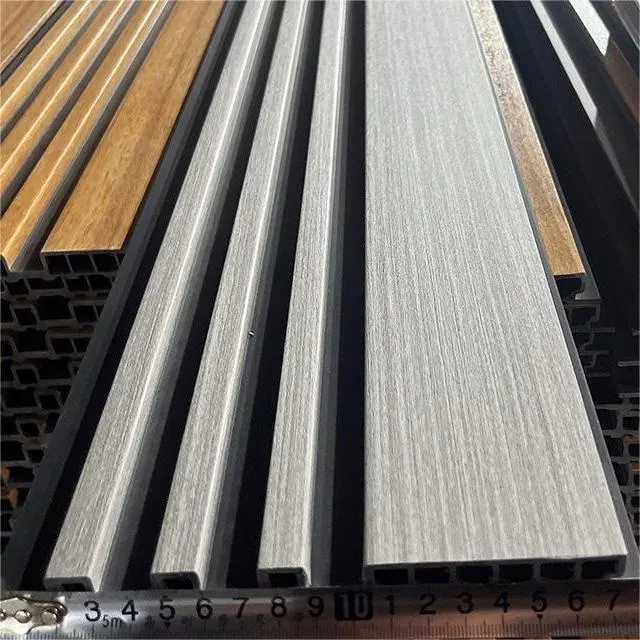

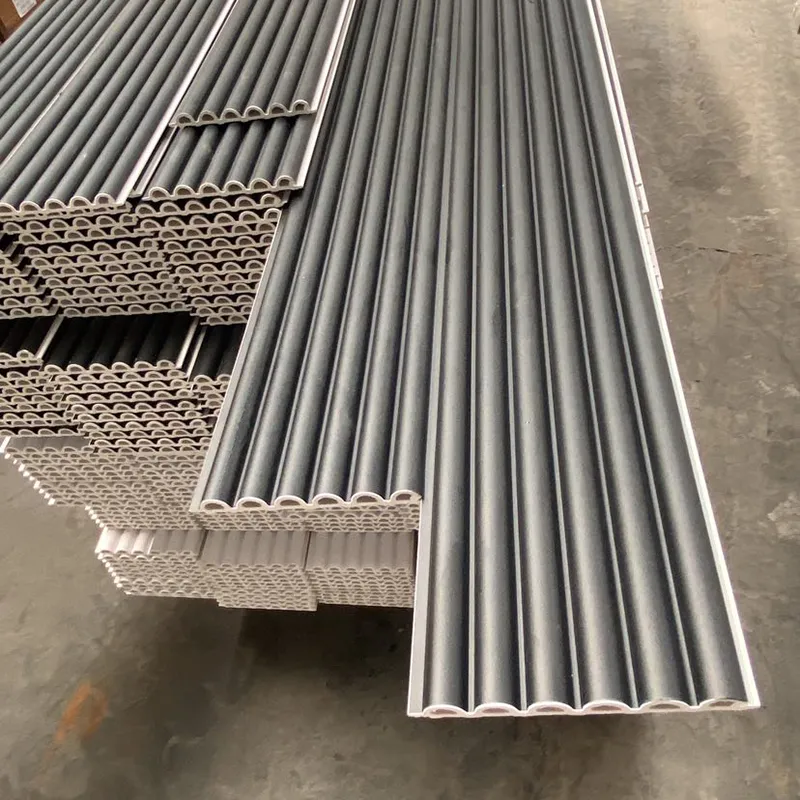

The manufacturing of high-quality wpc wall panel involves a sophisticated multi-stage process that meticulously transforms raw materials into durable, aesthetically pleasing, and highly functional building components. This process begins with the careful selection and preparation of raw materials, primarily wood fibers (such as wood flour from recycled timber or agricultural waste) and thermoplastic polymers (such as PVC, PE, or PP, often sourced from recycled plastics). These materials are precisely proportioned to achieve optimal mechanical properties and environmental stability. The first critical step is compounding, where wood fibers and polymers, along with various additives like coupling agents, UV stabilizers, pigments, and lubricants, are thoroughly mixed in high-temperature blenders. This stage ensures a homogeneous blend, where the wood fibers are effectively encapsulated by the polymer matrix, which is crucial for achieving superior moisture resistance and dimensional stability. Following compounding, the mixture is typically fed into an extrusion machine. In the extrusion process, the composite material is heated to its melting point and then forced through a die of a specific profile, forming the desired shape of the wall panel wpc. This continuous process allows for the production of panels with precise dimensions and consistent cross-sections, which is essential for uniform installation and structural integrity. Post-extrusion, the panels undergo a cooling process, often involving water baths or air cooling, to solidify their shape. Surface treatment is another vital stage, where panels can be embossed with wood grain textures, brushed for a natural feel, or coated with protective layers for enhanced UV resistance and scratch protection. This attention to detail in the manufacturing line ensures that the final product, such as the wpc fence panels for sale, meets stringent quality parameters, including uniformity in color, texture, and structural performance.

Quality control and adherence to industry standards are paramount throughout the WPC manufacturing process to guarantee product reliability and longevity. Post-production, each batch of wpc wallpanel undergoes rigorous testing protocols. These tests include evaluating mechanical properties such as flexural strength, impact resistance, and tensile strength, ensuring the panels can withstand various structural stresses. Dimensional stability is verified through measurements of expansion and contraction rates under fluctuating temperatures and humidity, ensuring minimal warping or buckling after installation. Furthermore, crucial environmental performance indicators are assessed, including water absorption rates, UV resistance, and resistance to fungal and insect degradation. These tests are often conducted in accordance with international standards such as ISO (International Organization for Standardization) and ASTM (American Society for Testing and Materials), which provide standardized methods for evaluating WPC products. For instance, ISO 178 outlines methods for determining flexural properties, while ASTM D7031/D7031M specifies physical and mechanical properties of WPC products. Compliance with these standards not only validates product quality but also provides assurance to B2B clients regarding performance consistency and safety. The average service life of well-manufactured wall panel wpc can exceed 20 years, even in demanding outdoor environments, a significant advantage over traditional wood products that typically require frequent maintenance and replacement. Applicable industries for WPC panels are remarkably broad, extending beyond traditional fencing and decking. They are increasingly utilized in diverse sectors such as residential construction for interior wall cladding and ceiling systems, commercial projects for office partitions and facades, hospitality for decorative elements, and even public infrastructure for sound barriers and pedestrian walkways. The innate resistance to moisture and corrosion makes them ideal for environments prone to humidity or chemical exposure, where materials like concrete, steel, or even certain timbers might degrade rapidly. This adaptability and long-term performance make wpc fence panels for sale a truly compelling material choice for a sustainable and durable future.

Technical Specifications and Performance Metrics of WPC Fence Panels

Understanding the detailed technical specifications of wpc fence panels for sale is crucial for B2B decision-makers, ensuring that selected products meet specific project requirements for performance, durability, and compliance. These panels are engineered with a precise blend of wood fiber and polymer resins, typically ranging from 50-60% wood fiber and 30-40% polymer (e.g., PVC, HDPE, PP), alongside 10-20% additives like anti-UV agents, colorants, and coupling agents. This formulation dictates many of their superior properties. For instance, the density of a typical WPC panel ranges from 1.0 to 1.4 g/cm³, providing a robust yet manageable weight. Flexural strength, a key indicator of resistance to bending, often exceeds 25 MPa (MegaPascals), demonstrating excellent structural integrity under load. Water absorption rates are remarkably low, usually less than 1.0% after 24 hours of immersion, which is critical for preventing swelling, rot, and mildew, especially in exterior applications. This low absorption rate also makes them highly resistant to environmental degradation, extending their functional lifespan significantly. UV resistance is another critical parameter, with high-quality panels showing minimal color fading or material degradation after accelerated weathering tests, ensuring aesthetic retention over decades. Fire performance characteristics vary based on formulation, but many WPC panels achieve a Class B or C fire rating according to ASTM E84 or similar standards, contributing to building safety. The temperature stability range is typically wide, from -40°C to +60°C, making them suitable for diverse climatic conditions without warping or cracking. These technical parameters collectively define the superior performance of wpc wall panel products, positioning them as a highly reliable alternative to traditional materials. Furthermore, the acoustic properties of WPC panels, though not their primary function, can contribute to sound dampening, especially in interior applications. Their stable composition also means they do not leach harmful chemicals, contributing to healthier indoor and outdoor environments.

| Parameter | Unit | Typical Value Range | Standard Reference (Example) |

|---|---|---|---|

| Material Composition (Wood Fiber) | % | 50 - 60 | Internal QA |

| Material Composition (Polymer) | % | 30 - 40 (PVC, HDPE, PP) | Internal QA |

| Density | g/cm³ | 1.0 - 1.4 | ASTM D7031 |

| Flexural Strength | MPa | 25 - 40 | ISO 178 / ASTM D7031 |

| Water Absorption (24h) | % | < 1.0 | ASTM D570 |

| UV Resistance (Color Change) | ΔE | < 3.0 (after 2000h QUV) | ASTM G154 / ISO 4892-3 |

| Fire Rating | Class | B or C | ASTM E84 |

| Service Temperature Range | °C | -40 to +60 | Internal QA |

| Termite Resistance | Rating | Excellent | ASTM D3345 |

| Mold and Mildew Resistance | Rating | Excellent | ASTM G21 |

The robust technical profile of wpc wallpanel translates directly into significant advantages across various application scenarios, making them a preferred material for demanding environments. For exterior applications, such as fencing, decking, and façade cladding, their exceptional weather resistance and minimal water absorption ensure long-term integrity without the need for painting, staining, or sealing, unlike traditional wood. This translates to substantial lifecycle cost savings due to reduced maintenance. In interior settings, for instance, as decorative wpc wall panel or ceiling systems, their resistance to moisture and mold makes them ideal for bathrooms, kitchens, and basements. Furthermore, WPC's acoustic properties can subtly contribute to sound dampening, enhancing comfort in enclosed spaces. The material's innate resistance to biological degradation—termites, fungi, and rot—eliminates common issues associated with organic materials, providing peace of mind and reducing replacement frequencies. This makes WPC particularly advantageous in regions with high humidity or pest infestation rates. From a sustainability perspective, the utilization of recycled materials in WPC production significantly reduces landfill waste and the demand for virgin timber, aligning with eco-conscious construction practices. The ease of installation, often featuring tongue-and-groove or clip systems, further accelerates project timelines and reduces labor costs. This combination of technical superiority, low maintenance, environmental benefits, and installation efficiency positions wpc wallpanel solutions as an intelligent, forward-looking choice for a diverse range of construction and design projects, offering compelling value propositions for contractors and property owners alike. The consistent performance metrics, verifiable through standardized testing, build significant trust among B2B clients who prioritize long-term investment value.

Key Advantages and Diverse Application Scenarios of WPC Panels

The proliferation of wpc wall panel across various sectors is a testament to its multifaceted advantages over conventional building materials. Primarily, WPC's exceptional durability and longevity stand out. Unlike natural wood, which is susceptible to rot, decay, and insect attacks, WPC panels are impervious to these biological threats. This inherent resistance significantly extends their service life, often exceeding 20 years, even in harsh outdoor environments or moisture-prone indoor areas like bathrooms and kitchens. This longevity translates directly into reduced replacement and maintenance costs for property owners and developers. Secondly, WPC is remarkably low-maintenance. It does not require painting, staining, or sealing, which are regular upkeep tasks for wood. A simple cleaning with soap and water is typically sufficient to maintain its aesthetic appeal, freeing up resources and time that would otherwise be spent on intensive upkeep. This characteristic is particularly appealing for large-scale commercial or public projects where maintenance efficiency is a critical factor. Thirdly, WPC offers excellent resistance to environmental factors. It exhibits minimal water absorption, preventing swelling, warping, and splintering. Its UV resistance ensures color stability and prevents degradation from prolonged sun exposure, crucial for exterior applications such as wpc fence panels for sale. Fourthly, WPC's sustainable profile is a significant advantage. Made from recycled wood fibers and plastics, it contributes to waste reduction and lessens reliance on virgin timber, aligning with global green building initiatives. This eco-friendly aspect enhances a project's sustainability credentials and appeals to environmentally conscious clients. Lastly, the aesthetic versatility of WPC allows for a wide range of design possibilities. Available in various colors, textures, and profiles, WPC panels can convincingly replicate the look and feel of natural wood, as well as offer modern, sleek finishes, catering to diverse architectural styles and design preferences. This blend of durability, low maintenance, environmental resilience, sustainability, and aesthetic flexibility makes WPC an increasingly favored material in modern construction.

The diverse technical advantages of WPC panels open up a myriad of application scenarios across residential, commercial, and public sectors. In residential contexts, wpc wall panel finds extensive use in interior applications such as decorative wall cladding for living rooms, bedrooms, and even moisture-prone areas like bathrooms and kitchens, where its water resistance is paramount. For exteriors, wpc fence panels for sale are highly sought after for privacy fences, garden walls, and perimeter enclosures due to their robust weather resistance and minimal upkeep. Decking and patio flooring are also major applications, providing durable, slip-resistant, and aesthetically pleasing outdoor living spaces. In commercial environments, WPC panels are utilized for office partitions, retail store facades, restaurant interiors, and hotel lobbies, where their design flexibility and durability contribute to a premium aesthetic and long-term performance. Their sound-dampening qualities can also be a subtle benefit in busy commercial settings. For public infrastructure, WPC is increasingly adopted for boardwalks, park benches, sound barriers along highways, and street furniture. Its resistance to vandalism, rot, and heavy pedestrian traffic makes it an ideal choice for high-use public spaces. Industrial applications, while less common for decorative panels, might involve WPC as protective cladding in specific non-corrosive environments or for specific structural elements where a blend of wood and plastic properties is beneficial. The inherent stability of WPC under varying temperatures and its anti-corrosion properties, particularly against moisture-induced decay, are critical advantages in these diverse settings. Unlike steel that can rust or concrete that can crack, WPC maintains its integrity. For example, in coastal regions, where salt spray and high humidity accelerate the degradation of many materials, WPC panels perform exceptionally, offering a long-lasting and resilient solution. This broad applicability underscores WPC's versatility as a high-performance building material, capable of enhancing both the functionality and visual appeal of any project.

Customization Capabilities and Comprehensive Solutions for WPC Projects

Leading manufacturers in the WPC industry understand that every project possesses unique requirements, necessitating robust customization capabilities and comprehensive solution offerings. Beyond standard dimensions and stock colors, the ability to tailor wpc wall panel products to exact specifications is a critical differentiator for B2B clients. This customization extends to various parameters, including panel dimensions (length, width, thickness) to minimize waste and optimize installation efficiency for specific architectural designs. Color matching is another essential service, allowing architects and designers to specify unique hues that seamlessly integrate with existing color schemes or brand identities. Advanced manufacturing processes enable the production of custom profiles and interlocking systems, facilitating easier and faster installation while ensuring a secure and aesthetic fit. Furthermore, specialized surface treatments can be applied to achieve desired textures—ranging from deep wood grain embossing for a rustic appeal to smooth, contemporary finishes for modern aesthetics. For projects requiring specific performance characteristics, manufacturers can adjust the WPC formulation by incorporating different polymer types (e.g., PVC for rigidity, HDPE for flexibility) or specialized additives. This allows for enhanced fire resistance, improved UV stability for extreme climates, or even anti-slip properties for high-traffic areas. Customization also includes the integration of unique design elements, such as perforated patterns for ventilation or specific branding elements. For instance, creating bespoke wpc fence panels for sale with integrated lighting channels or specific panel shapes for intricate landscape designs exemplifies the depth of customization available. This comprehensive approach ensures that the WPC solution is not merely a product but a perfectly engineered component of the overall project, delivering optimal performance and visual harmony. The close collaboration between clients and manufacturers from the design phase through to production ensures that every detail is meticulously addressed, resulting in a tailored product that precisely matches the envisioned outcome.

Beyond product customization, comprehensive solution providers in the wpc wall panel market offer a suite of services designed to support clients throughout the entire project lifecycle. This typically includes expert technical consultation, where experienced engineers and material scientists guide clients through material selection, design optimization, and performance considerations. Detailed CAD drawings and 3D renderings are often provided to visualize the final outcome and ensure precise fitment and aesthetic alignment. Project management support, from initial concept to final delivery, streamlines complex logistics, especially for large-scale international projects. Manufacturers also provide comprehensive installation guides and, in some cases, on-site technical support or training to ensure correct and efficient implementation of their wall panel wpc products. This reduces installation errors, minimizes waste, and ensures the product performs as intended. Post-sales support, including warranty services and responsive customer service, further reinforces client trust and satisfaction. For example, a global hotel chain renovating its outdoor spaces might require specific fire ratings for decking and bespoke patterns for privacy screens. A manufacturer offering comprehensive solutions would not only produce custom wpc fence panels for sale but also provide engineering analysis, compliance documentation, and logistical support to deliver to multiple international sites. This level of holistic support reduces the burden on clients, ensuring a smooth and successful project execution. The emphasis on tailored solutions and end-to-end support positions manufacturers not just as suppliers, but as strategic partners committed to delivering superior value and assisting clients in achieving their unique architectural and design visions, consistently meeting or exceeding project expectations with precision and expertise. This strategic partnership model is key for sustained success in the competitive B2B market.

Manufacturer Comparison and Partnership Value: Choosing Your WPC Supplier

Selecting the right manufacturer for wpc fence panels for sale is a critical decision for B2B entities, directly impacting project quality, cost-effectiveness, and long-term reliability. A comparative analysis of manufacturers should extend beyond mere pricing to encompass product quality, technological capabilities, adherence to international standards, and customer support. Leading manufacturers typically distinguish themselves through their investment in R&D, leading to patented technologies and superior product formulations that offer enhanced properties like greater UV resistance, better fire ratings, or unique surface finishes. For instance, a manufacturer that employs co-extrusion technology for its wpc wall panel products provides a denser, more durable outer layer that significantly boosts scratch and fade resistance compared to single-extruded panels. Certifications like ISO 9001 for quality management and ISO 14001 for environmental management are non-negotiable indicators of a manufacturer's commitment to excellence and sustainability. Furthermore, a manufacturer's track record, evidenced by successful large-scale project references and testimonials from reputable clients, speaks volumes about their reliability and expertise. Established players, often working as wpc wall panel wholesalers, possess extensive experience in navigating complex logistics and international trade, ensuring timely and efficient delivery, which is vital for maintaining project schedules. Their service longevity, perhaps spanning a decade or more, implies a deep understanding of market needs and a proven ability to adapt to evolving industry trends and technical demands. They also often have robust supply chain networks, minimizing potential disruptions. When comparing, evaluate their material sourcing practices – are they using high-quality recycled materials, and do they have ethical sourcing policies? Consider their production capacity; can they scale to meet large orders without compromising quality or lead times? These aspects collectively define the true value proposition of a WPC manufacturer, transcending basic product features.

The value of partnering with a reputable WPC manufacturer extends far beyond the product itself to encompass a comprehensive support system that ensures project success. A key aspect of this partnership value is the provision of in-depth technical support and consultation. This includes assisting clients with material selection, optimizing designs for specific applications, and ensuring compliance with relevant building codes and environmental regulations. For example, a client requiring wpc wall panel for a high-humidity environment will receive guidance on specific formulations that offer enhanced moisture resistance, along with technical data to support these claims. Reputable manufacturers also offer robust warranty programs, typically ranging from 10 to 25 years, providing peace of mind and demonstrating confidence in their product's durability and performance. This commitment to long-term quality assurance is a hallmark of an authoritative supplier. Their customer service excellence, characterized by responsiveness, problem-solving capabilities, and transparent communication, is crucial for fostering strong, lasting relationships. Active engagement in industry associations and continuous participation in trade shows further highlight a manufacturer's commitment to staying at the forefront of WPC technology and market trends. Furthermore, companies that prioritize sustainability and have verifiable environmental certifications (e.g., FSC for wood fiber sourcing, CE mark) add significant value, helping clients meet their green building objectives. Case studies and application success stories, demonstrating the effective use of their wpc wallpanel in diverse projects, provide tangible proof of their expertise and experience. This holistic approach, combining superior products with unparalleled service and industry authority, forms the foundation of a valuable strategic partnership, distinguishing market leaders in the competitive landscape of wpc wall panel wholesalers. Such partnerships enable B2B clients to leverage specialized knowledge and resources, ensuring that their projects are not only delivered on time and within budget but also achieve superior functional and aesthetic outcomes with long-term reliability.

Ensuring Trust: Quality Assurance, Certifications, and Customer Support

Building and maintaining trust with B2B clients is paramount in the WPC industry, and this is achieved through rigorous quality assurance, comprehensive certifications, and unwavering customer support. Leading manufacturers of wpc fence panels for sale implement multi-stage quality control protocols, beginning with the inspection of raw materials to ensure they meet stringent purity and composition standards. During the compounding and extrusion processes, continuous monitoring of temperature, pressure, and material flow ensures consistency and adherence to specified profiles. Post-production, each batch undergoes a series of physical and mechanical tests, including dimensional stability, flexural strength, impact resistance, and water absorption, as detailed in the technical specifications section. These tests are performed in state-of-the-art laboratories, often accredited to international standards, providing verifiable data that confirms product performance. External certifications are crucial validation points; ISO 9001 (Quality Management System) ensures consistent product quality, while ISO 14001 (Environmental Management System) demonstrates a commitment to sustainable manufacturing practices. Product-specific certifications, such as CE marking for European markets or ASTM compliance for North America, signify that the WPC panels meet specific regional safety, health, and environmental protection requirements. Some manufacturers also pursue certifications like FSC (Forest Stewardship Council) for responsibly sourced wood fibers, further enhancing their sustainability credentials. These rigorous quality frameworks and certifications provide a transparent guarantee of product integrity and reliability, allowing clients to proceed with confidence. This commitment to quality is what distinguishes a reliable supplier of wpc wall panel from others, providing documented proof of adherence to the highest industry benchmarks, ensuring that every panel delivered is consistently top-tier in terms of performance and durability, ultimately building long-term trust and loyalty with their professional clientele.

Beyond product quality, the trustworthiness of a wpc wall panel wholesaler is deeply rooted in their commitment to client service and support. A comprehensive FAQ module on a manufacturer’s website or in their technical documentation is invaluable, addressing common queries about installation, maintenance, and product performance. This proactive approach helps clients quickly find answers and troubleshoot minor issues, reducing reliance on direct support for routine questions. Clear and realistic delivery cycle explanations are essential for project planning; reputable suppliers provide detailed timelines from order confirmation to shipment, including estimated transit times for international deliveries. This transparency minimizes unexpected delays and allows B2B clients to manage their project schedules effectively. A robust warranty promise is a cornerstone of trust, often ranging from 10 to 25 years, covering manufacturing defects, rot, decay, and insect damage. This long-term commitment underscores the manufacturer's confidence in their product's durability and provides clients with crucial financial protection against premature product failure. Moreover, dedicated customer support channels—including direct phone lines, email support, and online portals—ensure that clients can access technical assistance, resolve issues, and receive responsive service when needed. This includes post-installation support for any unforeseen challenges or questions that may arise. For example, if a client has a query about cleaning protocols for a large installation of wall panel wpc, a responsive support team can provide immediate, expert advice. This unwavering dedication to customer satisfaction, coupled with transparent policies and reliable product quality, positions a manufacturer as a trusted partner, fostering enduring business relationships built on mutual confidence and shared success. This holistic approach to client engagement reinforces the company's authority and reliability in the WPC market.

Frequently Asked Questions (FAQ) about WPC Fence Panels

Q1: What exactly are WPC fence panels, and how do they differ from traditional wood or plastic fences?

WPC (Wood Plastic Composite) fence panels are engineered materials manufactured from a blend of recycled wood fibers (typically 50-60%), recycled thermoplastic polymers (like PVC, HDPE, or PP, making up 30-40%), and various additives (10-20%) that enhance properties such as UV resistance, color stability, and binding. Unlike traditional wood fences, WPC panels do not rot, warp, splinter, or succumb to insect infestation and fungal decay. This eliminates the need for regular painting, staining, or sealing, significantly reducing maintenance. Compared to pure plastic fences, WPC offers a more natural, wood-like aesthetic and tactile feel, along with superior structural rigidity and resistance to temperature fluctuations. They combine the best attributes of both materials: the durability and low maintenance of plastic with the natural appearance of wood. This unique composition makes wpc fence panels for sale an ideal, long-lasting solution for modern outdoor and even interior applications. Their composite nature provides enhanced dimensional stability, preventing the common issues associated with moisture absorption in pure timber, and offering greater resistance to weathering than unreinforced plastics. This makes them a high-performance, cost-effective alternative over their lifespan for a wide range of landscaping and building projects, ensuring both aesthetic appeal and robust functionality.

Q2: What is the typical lifespan of a WPC fence panel, and what kind of maintenance is required?

The typical lifespan of a high-quality wpc wall panel can range from 15 to 25 years, and often comes with a manufacturer's warranty of 10 to 25 years against defects, rot, decay, and insect damage. This longevity significantly surpasses that of traditional wooden fences, which typically last 5-15 years, often requiring substantial maintenance. The primary advantage of WPC panels is their minimal maintenance requirements. Unlike wood, they do not need to be painted, stained, or sealed annually or bi-annually. Routine cleaning is usually sufficient to maintain their appearance; a simple wash with soap and water or a mild pressure washer can remove dirt, grime, or superficial stains. For more stubborn marks, specialized WPC cleaners can be used. Occasional checks for debris accumulation in gaps or around posts are recommended, but major upkeep is largely unnecessary. This low-maintenance aspect translates into significant long-term cost savings in terms of labor and materials that would otherwise be spent on upkeep. The color stability of these panels, especially those with advanced UV inhibitors or co-extruded caps, ensures that their aesthetic appeal endures for decades, even under prolonged exposure to sunlight. This makes wpc wallpanel a truly set-it-and-forget-it solution, highly attractive for busy homeowners, commercial property managers, and public institutions seeking durable and low-upkeep fencing or cladding options.

Q3: Are WPC panels environmentally friendly, and what certifications should I look for?

Yes, wpc wall panel products are generally considered environmentally friendly due to several key factors. They are primarily manufactured from recycled materials, including post-industrial wood waste (sawdust, wood chips) and recycled plastics (such as HDPE, PVC, or PP from consumer waste). This significantly reduces landfill waste and decreases the demand for virgin timber, thus helping to conserve forests. Furthermore, the manufacturing process for WPC typically consumes less energy compared to alternatives like concrete or steel. Because WPC panels are incredibly durable and require minimal maintenance (no chemical treatments, paints, or stains), their environmental impact over their long lifespan is significantly lower. When looking for environmentally friendly WPC products, consider manufacturers that hold certifications such as ISO 14001 (Environmental Management System), which indicates responsible environmental practices during production. Additionally, certifications like FSC (Forest Stewardship Council) for the wood fiber component ensure that any virgin wood used is sourced from sustainably managed forests. Products with CE marking (for European markets) confirm adherence to health, safety, and environmental protection standards. By choosing certified wpc wall panel wholesalers, you ensure that the materials used in your project contribute to broader sustainability goals, supporting circular economy principles and reducing overall environmental footprint. This commitment to eco-conscious manufacturing not only benefits the planet but also enhances the green credentials of any construction project, aligning with modern corporate social responsibility initiatives.

Q4: Can WPC panels be customized in terms of color, size, or texture?

Absolutely. One of the significant advantages of wall panel wpc is their high degree of customizability, making them suitable for a vast array of architectural and design requirements. Manufacturers often offer a wide standard palette of colors, but many leading suppliers can provide custom color matching services to meet specific project aesthetics or branding guidelines. This allows designers to achieve precise visual continuity or unique design statements. In terms of size, WPC panels can be extruded into various lengths, widths, and thicknesses, significantly reducing waste and installation time on-site, particularly for large-scale projects. Custom profiles, including unique interlocking systems or decorative edge details, can also be developed to facilitate specific installation methods or to create distinct visual effects. Texture customization is another key area; panels can be produced with different surface finishes such as embossed wood grain, brushed, sanded, or smooth surfaces, each offering a different tactile and visual appeal. For enhanced performance, custom formulations incorporating specific additives can improve properties like fire resistance, anti-slip characteristics, or increased structural rigidity for specific load-bearing applications. This level of bespoke manufacturing ensures that wpc fence panels for sale are not merely off-the-shelf products but precisely engineered components tailored to the exact demands of any commercial or residential project, delivering both functional superiority and unparalleled aesthetic integration. This flexibility provides immense creative freedom for architects and designers, ensuring the final product perfectly aligns with their vision.

Conclusion: The Enduring Value of WPC Fence Panels in Modern Construction

The detailed exploration of wpc fence panels for sale reveals a material that stands at the intersection of innovation, sustainability, and high performance. From their sophisticated manufacturing processes, which meticulously blend recycled wood fibers and polymers, to their rigorous adherence to international quality standards such as ISO and ASTM, WPC panels represent a superior alternative to traditional building materials. Their technical parameters, including exceptional flexural strength, minimal water absorption, and robust UV resistance, ensure unparalleled durability and longevity across diverse applications. The inherent advantages of WPC—ranging from extreme resistance to rot, decay, and insect infestation to low maintenance requirements and significant environmental benefits due to recycled content—translate into compelling long-term value for B2B decision-makers. The versatility of wpc wall panel products, capable of being customized in terms of color, size, and texture, allows for seamless integration into any architectural design, from modern commercial facades to rustic residential fences. Furthermore, the commitment of reputable wpc wall panel wholesalers to comprehensive customer support, including detailed technical consultations, clear delivery schedules, and robust warranty programs, builds a foundation of trust essential for successful project execution. As the global construction industry increasingly prioritizes sustainable, durable, and aesthetically versatile solutions, WPC panels are poised to continue their trajectory as a material of choice. Their capacity to deliver both functional excellence and environmental responsibility ensures they remain a cornerstone in the evolution of modern, resilient, and eco-conscious building practices. Investing in WPC is not merely a material choice; it is a strategic decision for superior performance, reduced lifecycle costs, and enhanced sustainability, paving the way for a more resilient and aesthetically pleasing built environment for generations to come.

References

- ASTM International Standards for Wood-Plastic Composites. Available from: www.astm.org

- ISO Standards for Plastics and Polymer Composites. Available from: www.iso.org

- Forest Stewardship Council (FSC) Certification Standards for Forest Management. Available from: www.fsc.org

- European Committee for Standardization (CEN) Standards for Wood-Plastic Composites. Available from: www.cencenelec.eu

- Building Research Establishment (BRE) Guidelines for Sustainable Materials. Available from: www.bregroup.com

-

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >Aug 05 2025

-

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >Aug 05 2025

-

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >Aug 05 2025

-

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >Aug 05 2025

-

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >Aug 05 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com