Ultimate WPC Exterior Wall Cladding - Waterproof & Durable

In the age of innovative architecture, WPC exterior wall cladding is redefining standards for sustainable, aesthetically pleasing, and high-performance building envelopes. Integrating wpc wall panel outdoor, exterior wpc wall panel, wpc wall panel exterior, and wpc outdoor wall cladding, this technology leverages Wood-Plastic Composite (WPC) advancements to deliver a solution that withstands the rigors of outdoor environments while offering significant design flexibility.

Industry Trends: The Rise of WPC Exterior Wall Cladding

As environmental sustainability and maintenance-free solutions dominate construction priorities, WPC exterior wall cladding has seen a compound annual growth rate (CAGR) of 11% in the global market (2021-2026, Markets and Markets). Architects, developers, and engineers are increasingly choosing WPC panels for their weather resistance, color retention, and eco-friendly credentials.

- Annual installations in Europe up by 18% since 2020

- Expected global market size: $6.5 billion by 2026

- Key drivers: Urbanization, renovation trends, durability mandates

Technical Specifications and Industry Parameters

WPC exterior wall cladding is engineered by blending wood fibers and high-density polyethylene (HDPE) or polyvinyl chloride (PVC), reinforced with UV stabilizers. Key technical performance parameters are crucial for ensuring optimal performance, which include mechanical strength, colorfastness, dimensional stability, and fire resistance.

| Property | WPC Exterior Wall Cladding | Aluminum Panel | Fiber Cement | Natural Timber |

|---|---|---|---|---|

| Density (kg/m³) | 1,200 - 1,450 | 2,700 | 1,400 | 500 - 700 |

| Water Absorption (%) | < 1.2 | < 0.1 | 12 - 15 | 8 - 16 |

| UV Resistance | Excellent (ASTM G154) | Very Good | Good | Poor |

| Fire Rating | B1 (EN13501-1) | A2 | A1 | Not Rated |

| Lifespan (years) | > 25 | > 30 | 20 - 30 | 10 - 15 |

| Maintenance | Minimal | Powder Coating | Painting Required | Annual Staining |

| Eco-Friendliness | High (Recycled) | Recyclable | Low to Medium | Variable |

- ISO 9001 Quality Management

- EN 15534 for WPC products in exterior applications

- ASTM G154 – Accelerated Weathering Tests

- EN 13501-1 – Fire Rating for Cladding

WPC Exterior Wall Cladding Manufacturing Process

The WPC exterior wall cladding from Sothink Decor follows a meticulously controlled production process. It ensures optimal blend consistency, structural integrity, and surface finish required for demanding outdoor applications.

Raw Material Selection

Wood Fiber (60%)

HDPE/PVC (30%)

Additives (10%)

Compounding & Mixing

Twin-Screw Extrusion

Extrusion Shaping

CNC Calibration

Surface Texturing

Brushing/Embossing

Cooling & Cutting

Precision Sawing

Quality Inspection

ISO/ASTM/EN Tests

Packing & Logistics

Customization

Watch the manufacturing process video: WPC Cladding Production Walkthrough (YouTube)

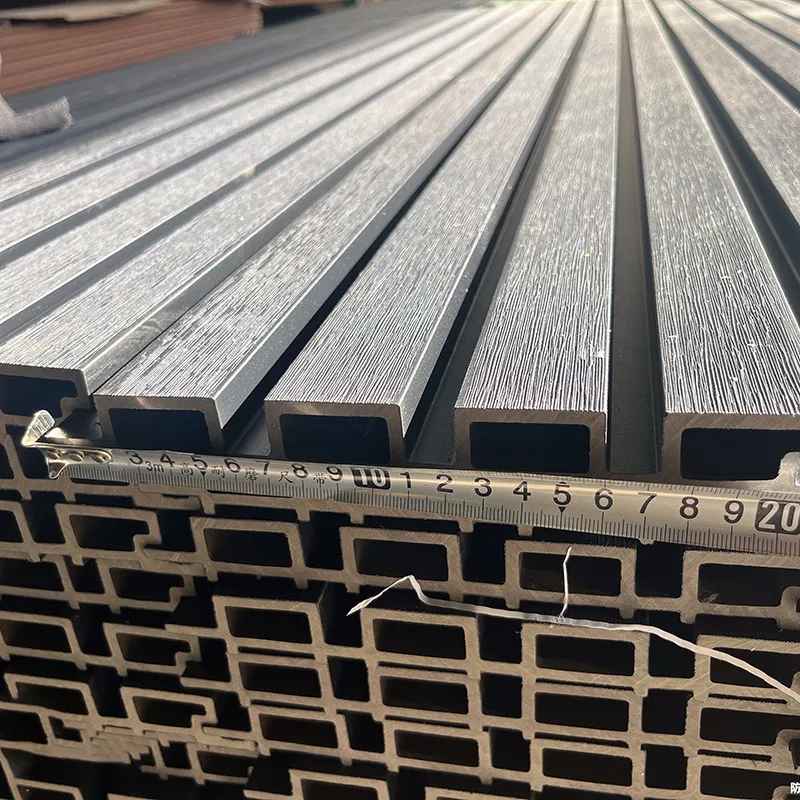

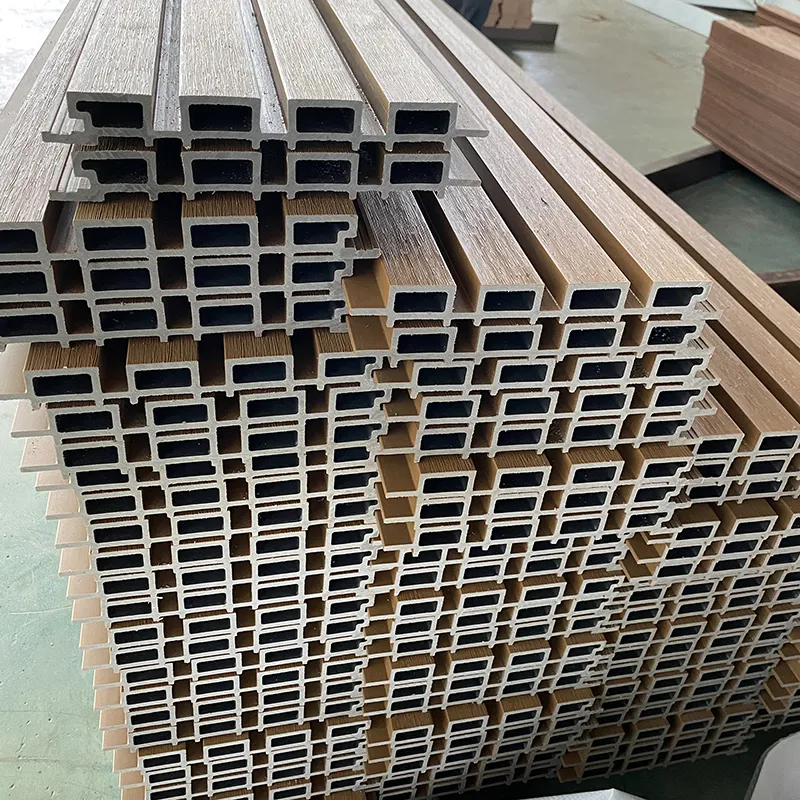

WPC Exterior Wall Cladding: Product Data & Specification Table

| Parameter | Typical Value | Standard / Test Method |

|---|---|---|

| Dimensions (L x W x T) | 2200 x 150 x 21mm (Customizable) |

EN 15534-1 |

| Density | 1,350 kg/m³ | ISO 1183 |

| Bending Strength | > 30 MPa | EN 310 |

| Water Absorption (24h) | < 1.0% | EN 317 |

| UV Resistance | ΔE < 5 (after 2,000 h) | ASTM G154 |

| Fire Classification | B1 (hardly inflammable) | EN 13501-1 |

| Thermal Expansion | 0.04 mm/m·K | EN 15534-1 |

| Expected Service Life | > 25 years | ISO 14001 |

Data Visualization: Performance Analysis

Application Scenarios & Industry Use Cases

Sothink Decor’s WPC exterior wall cladding is engineered for the most demanding outdoor applications where safety, durability, and visual quality are paramount. Industry usage spans a variety of demanding sectors:

- Commercial office complexes (energy-efficient renovation projects)

- Public buildings (schools, libraries – improved fire and impact safety)

- Hospitality resorts (weather-resistant, anti-fade beachfront facades)

- Industrial facilities (chemical, petrochemical, metallurgy)

- Residential high-rises and villas (aesthetic, low-maintenance exteriors)

- Infrastructure projects (transport hubs, airports, sports venues)

Example: In a 2022 retrofit of a Shanghai commercial center, Sothink’s WPC cladding reduced annual exterior maintenance costs by 72%, while extending facade service life by 19+ years compared to painted timber.

Technical Advantages: Why Choose WPC Exterior Wall Cladding?

- Engineered Durability: Composite matrix and high-quality pigments resist UV, cracking, delamination, and corrosion in severe weather zones.

- Fire Safety: B1 fire classification limits flame spread, suitable for public/commercial builds.

- Low Maintenance: Requires only periodic rinsing, outperforming timber (no rot, termites, or warping).

- Design Flexibility: Multiple finishes (embossed wood grains, sleek modern lines), custom profiles/colors upon request.

- Eco-Friendly: High recycled content, formaldehyde- and lead-free, certified to EN 15534.

- Thermal & Acoustic Insulation: Provides enhanced building envelope performance, reduces energy loss (thermal conductivity ≈0.20 W/m·K).

- Consistency: CNC-controlled extrusion ensures precisely repeatable dimensions for modular construction.

Manufacturers Comparison: Top Brands in WPC Exterior Wall Cladding

| Manufacturer | Raw Material | Standard Certifications | Warranty | Customization | Major Markets |

|---|---|---|---|---|---|

| Sothink Decor | Recycled HDPE + Pine Fiber | EN15534, ISO9001 | 15 Yr | Finish/Color/Dim | Asia, EU, NA |

| Fiberon | PVC + Maple Fiber | ASTM, Intertek | 25 Yr | Color/Format | NA, EU |

| Trex | Recycled PE + Oak Fiber | ISO14001, EN13501 | 20 Yr | Texture/Dim | NA, EU |

| Techwoodn | PVC+Teak Fiber | EN15534, CE | 15 Yr | Finish/Dim | Asia, ME |

Customization Options & Delivery Commitment

Sothink Decor provides flexible customization for wpc exterior wall cladding projects:

- Profile shapes: Flat, grooved, louvered

- Surface: Deep-embossed, brushed, exotic wood imitation

- Dimensions: Lengths from 1.8m-4.5m, widths 120-215mm, thicknesses 16-30mm

- Colors: 12 standard, 180+ optional (including RAL/Pantone matching)

Lead time: Standard models 10-14 days | Custom runs 18-28 days

Warranty: Minimum 15 years (with Sothink Decor extended warranty program)

Selected Application Cases & Client Feedback

"We retrofitted our seafront hotel with wpc wall panel exterior cladding from Sothink Decor. In 20 months, there’s no fading or warping. Maintenance costs dropped from $42/m²/year (timber) to less than $9/m²/year." – Mr. Zhao, Project Manager, Hainan Gold View Hotel

- Case 1: City Commercial Plaza, Guangzhou: 5,800m² cladding, energy cost cut by 13%

- Case 2: Industrial Park, Qingdao: Acid-resistant WPC panels used for chemical warehouse elevations

- Case 3: Sports Arena, Germany: Custom extrusion for dynamic facade design with brushed surface finish

Professional FAQ: Top Technical Questions on WPC Exterior Wall Cladding

After-Sales Support, Quality Commitment, and Customer Service

- Fast Response: Technical support within 2h

- Delivery Guarantee: Late shipments penalized per contract. Online order tracking available.

- Extended Warranty: Up to 20 years for color retention and structural integrity (consult Sothink Decor)

- On-site Guidance: Installation guidance, CAD detail drawings, and ongoing technical support

Conclusion & Industry References

The evolution of wpc exterior wall cladding is transforming the landscape of facade engineering, fusing advanced composites technology with design innovation and environmental stewardship. For architects, builders, and facility managers seeking long-term performance, reduced operational costs, and sustainable beauty, WPC cladding stands as an industry-leading solution.

-

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >

WPC Wall Panel Outdoor Weather ResistanceModern exterior design solutions increasingly utilize WPC exterior wall cladding for its exceptional durability and aesthetic appeal.Read More >Aug 05 2025

-

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >

WPC Wall Panel for Wine CellarsThe ideal wine cellar requires specialized wall solutions that perfectly balance functionality and aesthetics.Read More >Aug 05 2025

-

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >

WPC Wall Panel Expansion GapsProfessional installation of WPC wall cladding requires meticulous attention to expansion gap requirements to ensure long-term durability and aesthetic performance.Read More >Aug 05 2025

-

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >

SPC Flooring Stone Look Outdoor UseOutdoor living spaces now benefit from durable and stylish SPC floor tiles that combine the beauty of natural stone with exceptional performance.Read More >Aug 05 2025

-

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >

Marble Effect PVC Panels Color OptionsModern interior design increasingly utilizes marble effect PVC panels for their luxurious appearance and practical benefits.Read More >Aug 05 2025

+86 31185293045

+86 31185293045  qian@ss711.com

qian@ss711.com